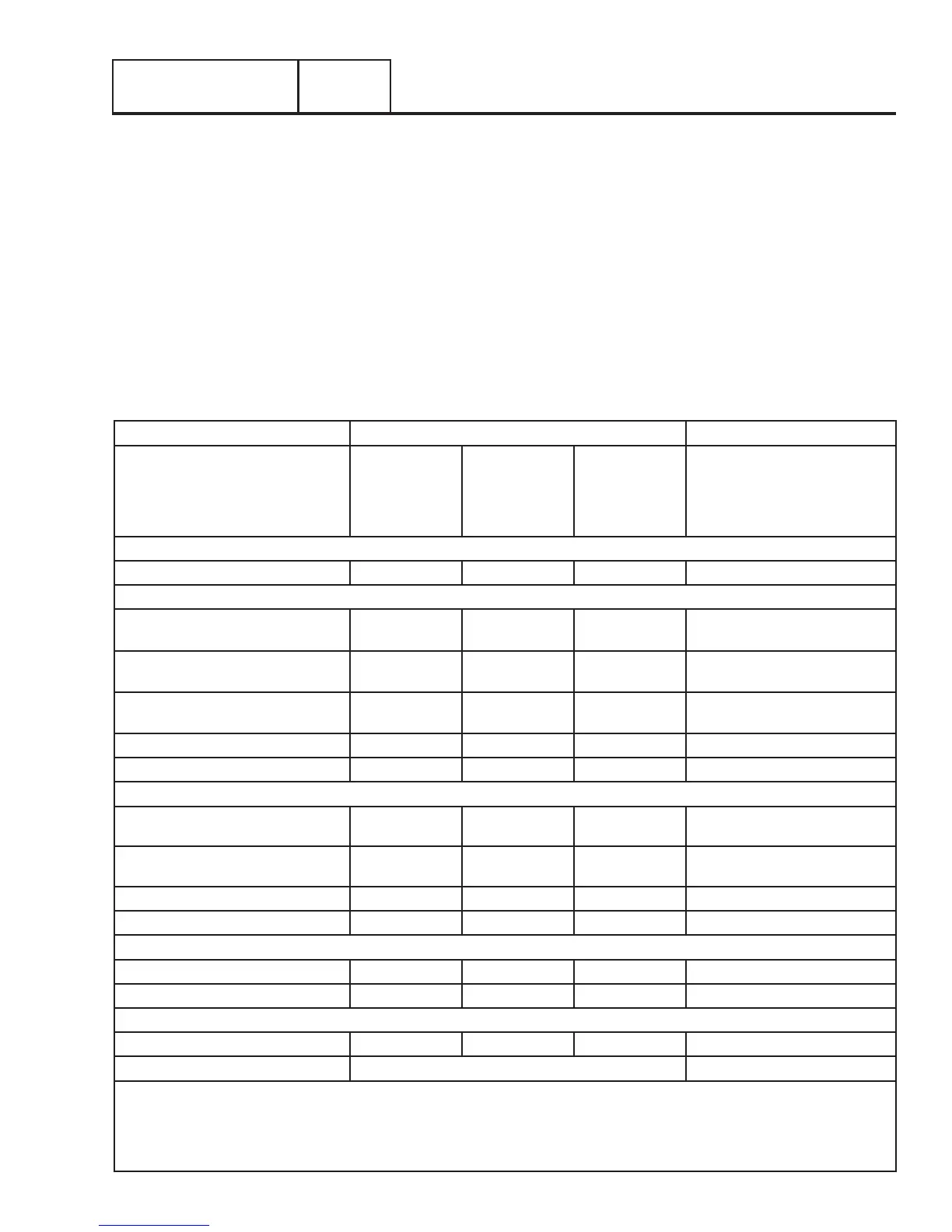

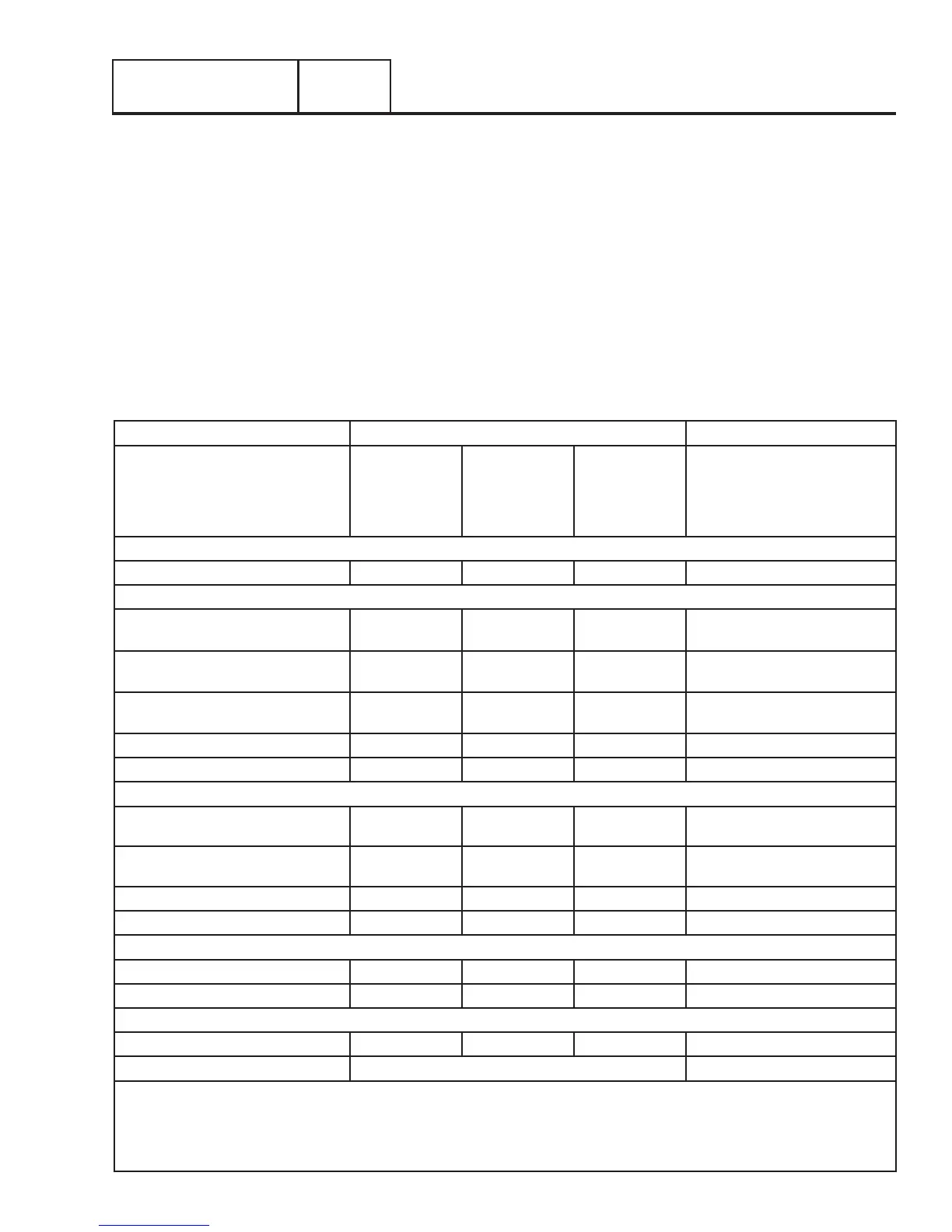

Table 1. Service Schedule

SYSTEM/COMPONENT PROCEDURE FREQUENCY

X = Action

R = Replace as Necessary

* = Notify Dealer if Repair is

Needed.

Inspect Change Clean

W = Weekly

M = Monthly

Y = Yearly

FUEL

Fuel lines and connections*

X M

LUBRICATION

Oil level

X M or 24 hours of

continuous operation.

Oil

X 1Y or 100 hours

of operation.**

Oil filter

X 1Y or 100 hours

of operation.**

COOLING

Enclosure louvers

X X W

BATTERY

Remove corrosion, ensure

dryness

X X M

Clean and tighten battery

terminals

X X M

Check charge state

X R EVERY 6 M

Electrolyte level

X R EVERY 6 M

ENGINE AND MOUNTING

Air cleaner

X R 1Y or 200 hours

Spark plug

X R 1Y or 200 hours

GENERAL CONDITION

Vibration, Noise, Leakage, Temperature*

X M

COMPLETE TUNE-UP* TO BE COMPLETED BY A DEALER 1Y or 200 hours

* Contact the nearest dealer for assistance if necessary.

** Change oil and filter after first eight (8) hours of operation and then every 100 hours thereafter, or 1 year, whichever occurs first.

Change sooner when operating under a heavy load or in a dusty or dirty environment or in high ambient temperatures.

GENERAL INFORMATION

PART 1

Page 21

Section 1.6

General Maintenance

BATTERY

Performing proper battery maintenance at the required intervals

will allow for proper starting of the Generator during a power

outage. Some common things to look for and check during

maintenance are:

•Inspect the battery posts and cables for tightness and

corrosion. Tighten and clean as necessary.

•Check the battery fluid level of unsealed batteries and, if nec-

essary, fill with Distilled Water only. Do not use tap water in

batteries.

•Have the state of charge and conditions checked. This should

be done with an automotive-type battery hydrometer.

Note: See Test 56 for further testing the state of a battery.

Loading...

Loading...