PART 2

AC GENERATORS

Page 32

Section 2.4

Diagnostic Tests

21. Set the AUTO-OFF-MANUAL switch to the MANUAL

position.

22. Measure and record the running DC amperage.

23. Set the AUTO-OFF-MANUAL switch to the OFF position

and reconnect the wires to the voltage regulator.

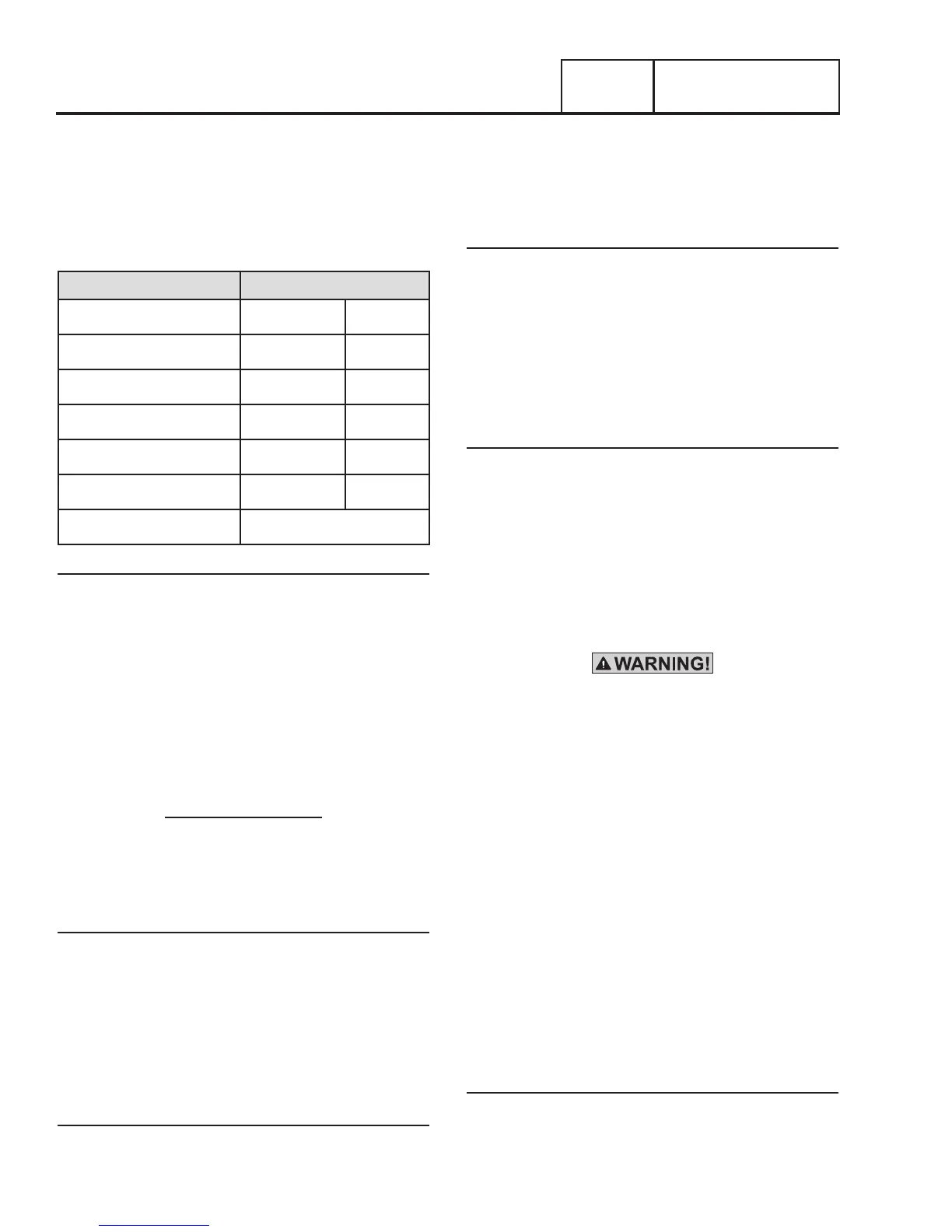

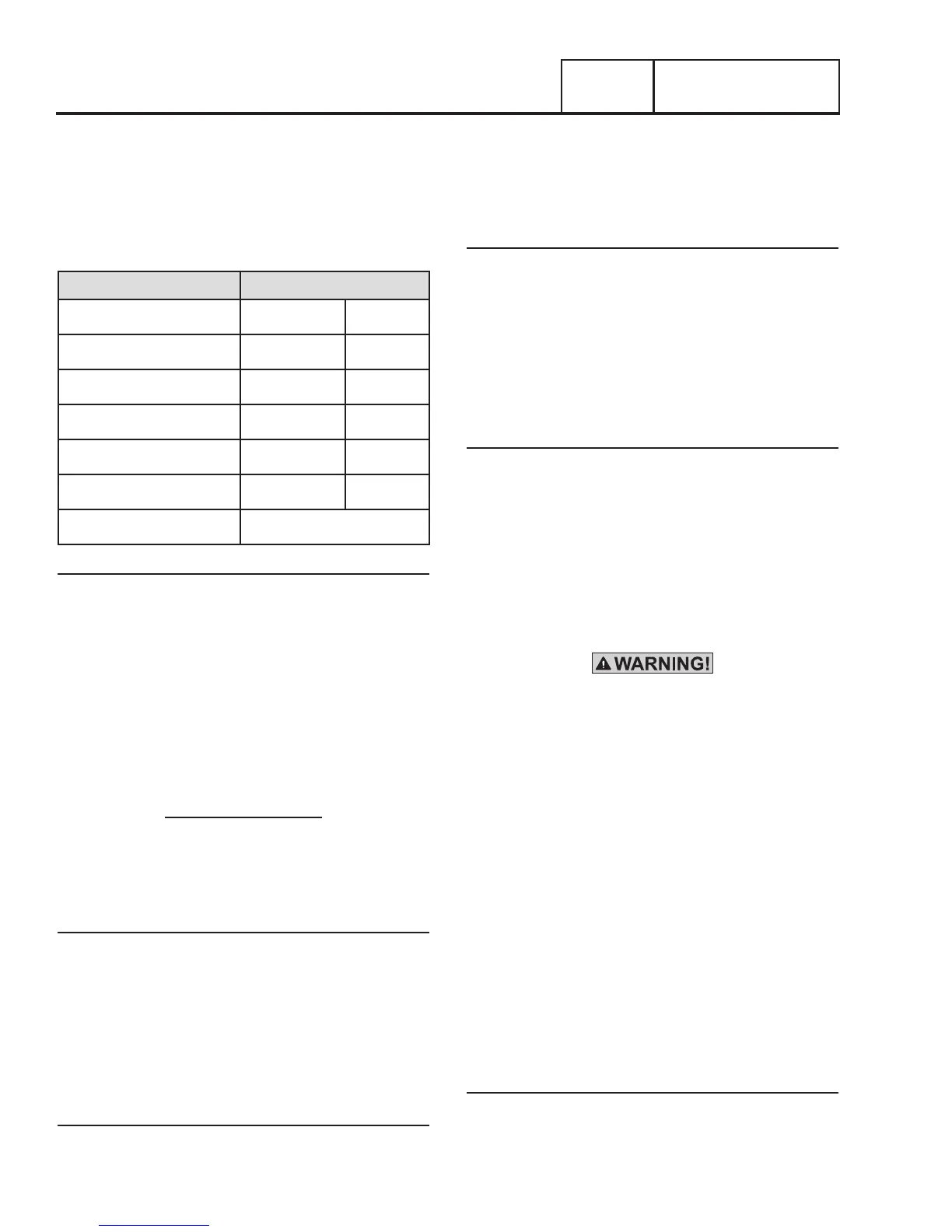

Table 3. Test 4 Results Worksheet

Test Point Results

Rotor Resistance

Ohms

Battery Voltage

VDC

Blue to Blue Voltage

VAC

White and Blue Voltage

VAC

Static Rotor Amp Draw

Amps

Running Rotor Amp Draw

Amps

Column Identified

Results

1. Using the values recorded in the above procedures,

compare the results to Table 2 “Test 4 Results – Fixed

Excitation Test”. Determine the appropriate lettered

column to use and refer back to the flow chart. The

rotor amp draws are a calculated amp draw and actual

amperage readings may vary depending on the resistance

of the rotor and battery voltage.

Note: To calculate rotor amp draw take the battery voltage

applied, divided by the actual resistance reading of the

rotor. Rotor resistance can be measured between the RED

and BLACK wires going to the voltage regulator.

12.9VDC

50 Ohms x .258 DC Amps

TEST 6 – RESISTANCE CHECK OF ROTOR

CIRCUIT

Procedure

1. Locate and disconnect the Red and Black wires from the

voltage regulator.

2. Set a Volt-Ohm-Milliammeter (VOM) to measure

resistance.

3. Connect meter test leads across the female Red and Black

wires at connector disconnected in Step 1. Measure and

record the resistance.

Results

1. If the VOM indicate a resistance of approximately 40

ohms ± 20 ohms, verify rotor amp draw.

2. If the VOM did not indicate the proper resistance, refer

back to flow chart.

TEST 7 – CHECK BRUSHES AND SLIP RINGS

Discussion

The brushes and slip rings function to provide an electrical

connection for excitation current from the stationary

components to the rotating rotor. Made of a special long

lasting material, brushes seldom wear out or fail. However,

slip rings can develop a tarnish or film that can inhibit or offer

a resistance to the flow of current. Such a non-conducting

film usually develops during non-operating periods. Broken or

disconnected wiring can also cause loss of excitation current

to the rotor.

Procedure

1. Disassemble the Generator until the brushes and slip rings

are exposed. Refer to Section 5.1 “Major Disassembly.”

2. Inspect the brush wires and verify they are secured and

properly connected.

3. Inspect the brush assembly for excessive wear, or

damage.

4. Inspect the rotor slip rings. If their appearance is dull or

tarnished, polish with a fine grade abrasive material.

Do not use metallic grit to polish slip rings. This may

cause irreversible damage to the rotor.

5. The Black Wire, located on the negative brush terminal,

provides an electrical connection to the voltage regulator.

To test this wire for an OPEN condition, remove the Black

Wire from the brush assembly.

6. Set Volt-Ohm-Milliammeter (VOM) to measure resistance.

7.

C

onnect one meter test lead to the Black Wire at the brush

assembly and connect the other meter test lead to the

Black wire at the voltage regulator.

•If the VOM indicated INFINITY, repair or replace the Black

Wire between the negative slip ring and the voltage regulator.

•If the VOM indicated CONTINUITY, continue to Step 8.

8. Disconnect the Red Wire from the brushes.

10. Connect one meter test lead to the Red Wire disconnected

at the brushes and the other meter test lead to the Red

wire disconnected at the voltage regulator.

Results

1. Repair, replace, or reconnect wires as necessary.

2. Replace any damage slip rings or brush holder.

3. Clean and polish slip rings as required.

Loading...

Loading...