ENGINE/DC CONTROL

PART 4

Page 69

Section 4.5

Diagnostic Tests

TEST 62 – CHECK FUEL SOLENOID

Discussion

In Test 61, if battery voltage was delivered to Wire 14, the

fuel solenoid should have energized open. This test will verify

whether or not the fuel solenoid is operating.

Fuel Solenoid FS1 Nominal Resistance – 14-16 ohms.

Procedure

1. Install a manometer to Port 2 on the fuel regulator. See

Figure 47.

2. Set the AUTO-OFF-MANUAL Switch to MANUAL.

3. Proper gas pressure should be measured during cranking.

If gas pressure is measured, the fuel solenoid is operating.

If gas pressure is not measured, repair or replace the fuel

solenoid.

Results

Refer to flow chart.

TEST 63 – CHECK CHOKE SOLENOID

Discussion

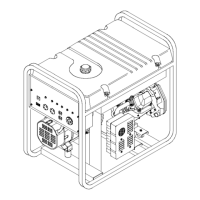

The automatic choke cycles open and closed during cranking

and remains de-energized in the open position during running.

Procedure

1. Turn off the fuel supply to the generator.

2. Set the AUTO-OFF-MANUAL Switch to the MANUAL

position.

3. While cranking the choke solenoid should energize and

pull the choke plate closed and release back to the open

position as the solenoid cycles during cranking. If the

choke solenoid does not cycle, verify that the choke

can be manually closed. There should be no binding or

interference.

Figure 48. Choke Solenoid and Choke Valve Plate

4. Disconnect the Choke Solenoid Connector.

5. Set a VOM to measure DC voltage.

6. Connect the positive (+) test lead to Wire 56 (Pin 1)

of the connector going to the controller (Female Side)

Connect the negative (-) test lead to Wire 90 (Pin 2).

7. Set the AUTO-OFF-MANUAL Switch to MANUAL. While

cranking, battery voltage should be measured . If battery

voltage was not measured, verify continuity of Wire 90

between the Choke Solenoid Connector and J2-15 (Wire

90) at the controller. Verify continuity of Wire 56 between

the Choke Solenoid Connector Wire 56 and J2-11 (Wire

56). Repair or replace any wiring as needed.

8. Set a VOM to measure resistance.

9. Connect the positive (+) test lead to Wire 56 (Pin 1) of

Choke Solenoid Connector going to the choke solenoid

(Male Side). Connect the negative (-) test lead to Wire 90

(Pin 2). Approximately 3.7 ohms should be measured.

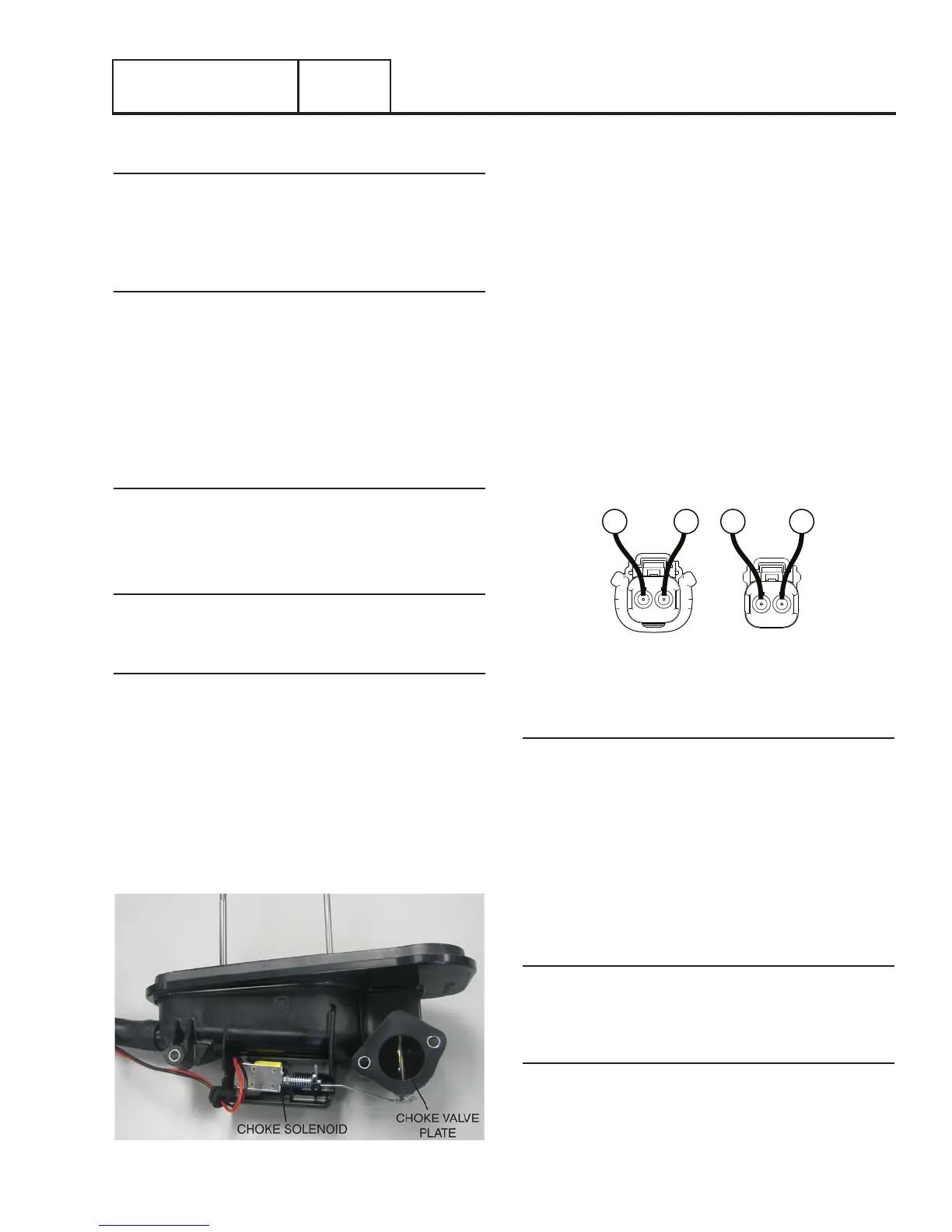

FEMALE SIDE

MALE SIDE

2 1

1 2

90

9056

56

Figure 49. Choke Solenoid Connector

Results

1. If battery voltage was not measured in Step 7 and wire

continuity is good, replace the controller.

2. If Choke Solenoid coil resistance is not measured in Step

9, replace the Choke Solenoid.

3. If battery voltage was not measured in Step 4, replace the

controller.

TEST 64 – CHECK FOR IGNITION SPARK

Discussion

If the engine cranks but will not start, perhaps an ignition

system failure has occurred. A special “spark tester” is required

to check for ignition spark.

Procedure

1. Remove spark plug lead from the spark plug.

2. Attach the clamp of the spark tester to the engine

cylinder head.

3. Attach the spark plug lead to the spark tester terminal.

Loading...

Loading...