PART 4

ENGINE/DC CONTROL

Page 72

Section 4.5

Diagnostic Tests

•Blown or leaking cylinder head gasket

•Improperly seated or sticking-valves

•Worn piston rings or cylinder. ( This will also result in a high

oil consumption)

The minimum allowable compression pressure for a cold engine

is 60 PSI. Compression values are difficult to obtain accurately

without special equipment. For this reason, compression

values are not published for the larger engines. However,

testing has proven that an accurate indication of compression in

the cylinder can be obtained by using the following procedure.

Note: Refer to Manufacturer's instructions for variations of

this procedure.

Procedure

1. Remove the spark plug.

2. Insert a compression gauge into the cylinder.

3. Crank the engine until there is no further increase in

pressure.

4. Record the highest reading obtained.

5. Repeat the procedure for the remaining cylinder and

record the highest reading.

Results

The minimum allowable compression pressure for a cold

engine is 60 PSI. If compression is poor, look for one or more

of the following causes:

•Loose cylinder head bolts

•Failed cylinder head gasket

•Burned valves or valve seats

•Insufficient valve clearance

•Warped cylinder head

•Warped valve stem

•Worn or broken piston ring(s)

•Worn or damaged cylinder bore

•Broken connecting rod

•Worn valve seats or valves

•Worn valve guides

TEST 67 – CHECK IGNITION COIL

Discussion

The ignition system is a solid-state (breakerless) type. The

system utilizes a magnet on the engine flywheel to induce a

relatively low voltage into an ignition coil assembly. Ignition

coil internal components increase the voltage and deliver the

resulting high voltage across the spark plug gap.

The ignition coil houses a solid-state circuit that controls

ignition timing. Timing is fixed, air gap is non-adjustable and

spark advance is automatic.

Major components of the ignition system include (a) the ignition

coil assembly, (b) the spark plug, and (c) the engine flywheel.

Solid-state components encapsulated in the ignition coil are not

accessible and cannot be serviced. If the coil is defective, the

entire assembly must be replaced. The air gap between the coil

and the flywheel magnet is fixed and non-adjustable.

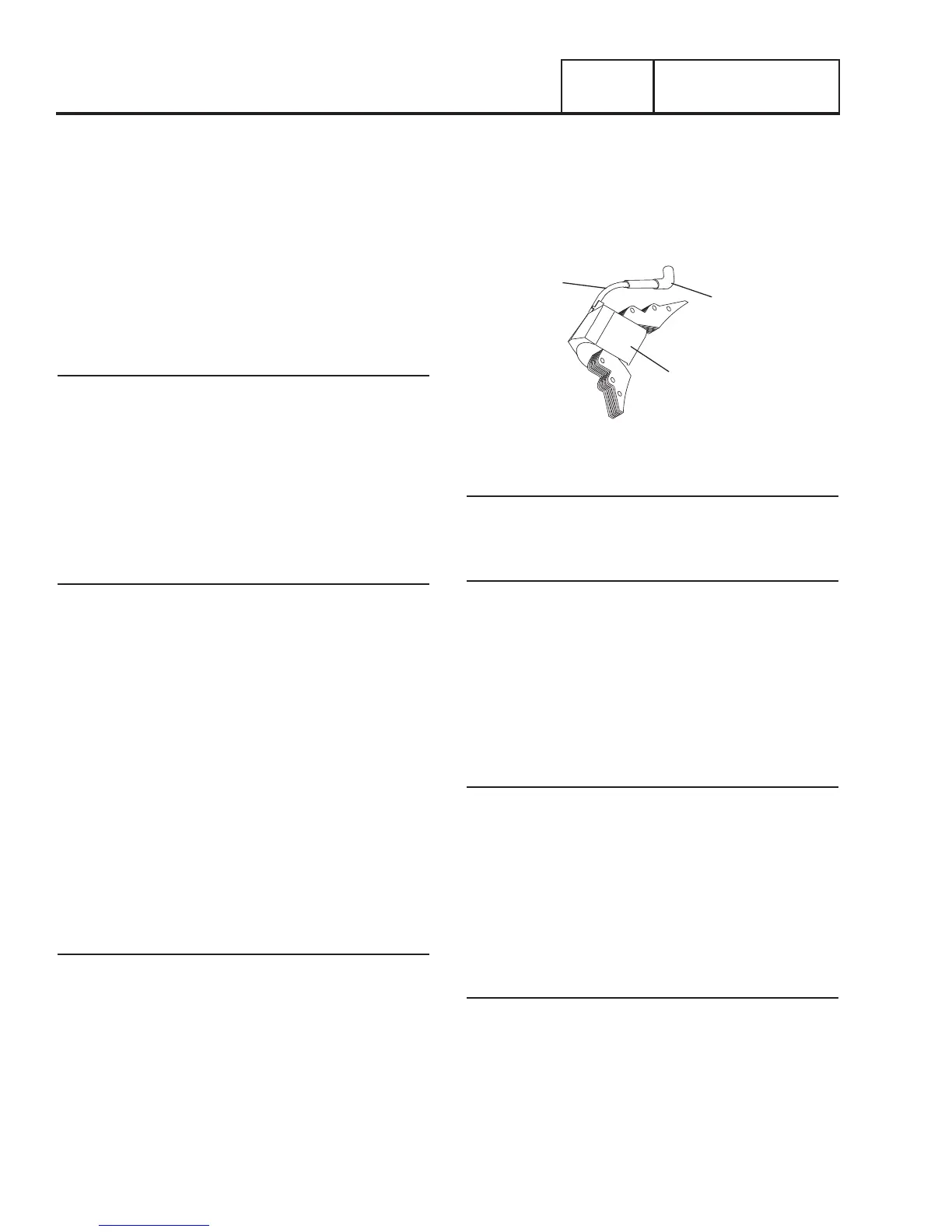

The ignition coil assembly (Figure 56) consists of (a) ignition

coil, (b) spark plug high tension lead and (c) spark plug boot.

SPARK PLUG

HIGH TENSION

LEAD

SPARK

PLUG

BOOT

IGNITION COIL

Figure 56. Ignition Coil

Procedure

1. Disconnect Wire 18 at the bullet connector and repeat

Test 67.

Results

1. If unit was able to produce spark after disconnecting Wire

18 then a short to ground is supplying Wire 18 with a

ground that is inhibiting the engine from producing spark.

2. If the Ignition Coil failed to produce spark with Wire 18

disconnected, verify integrity of Wire 18 under cover, then

replace ignition coil.

Note: Before replacing the Ignition Coil, check the flywheel

key.

Flywheel Key

In all cases, the flywheel’s taper is locked on the crankshaft

taper by the torque of the flywheel nut. A keyway is provided for

alignment only and theoretically carries no load.

If the flywheel key becomes sheared or even partially sheared,

ignition timing can change. Incorrect timing can result in hard

starting or failure to start.

TEST 68 – CHECK OIL PRESSURE SWITCH

AND WIRE 86

Discussion

If the oil pressure switch contacts have failed in their closed

position, the engine will probably crank and start. However,

shutdown will then occur within about 5 (five) seconds. If the

engine cranks and starts, then shuts down almost immediately

with a LOP fault light, the cause may be one or more of the

following:

•Low engine oil level.

•Low oil pressure.

•A defective oil pressure switch.

Loading...

Loading...