PART 4

ENGINE/DC CONTROL

Page 70

Section 4.5

Diagnostic Tests

4. Crank the engine while observing the spark tester. If spark

jumps the tester gap, you may assume the engine ignition

system is operating satisfactorily.

NOTE: The engine flywheel must rotate at 350 rpm (or high-

er) to obtain a good test of the solid state ignition system.

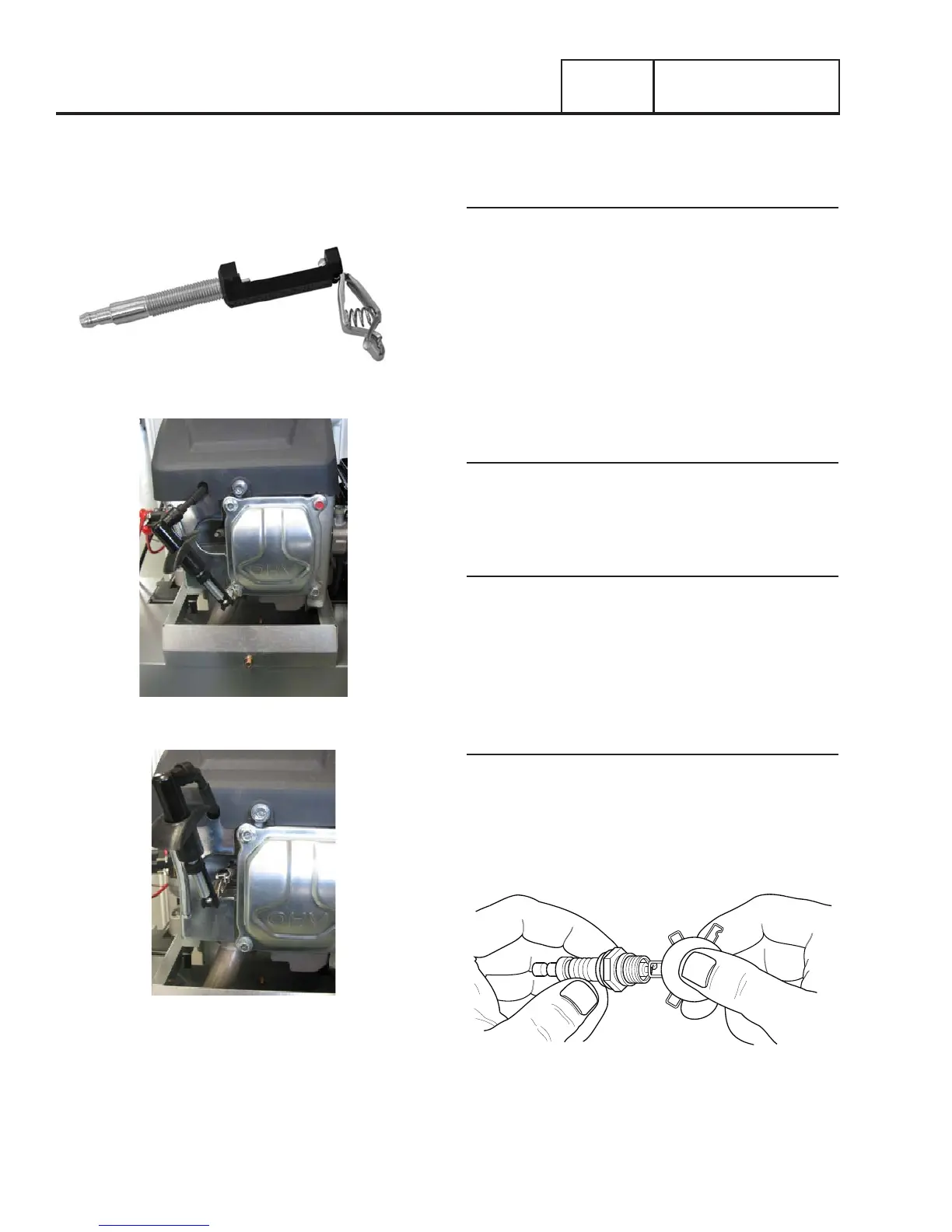

Figure 50. Spark Tester

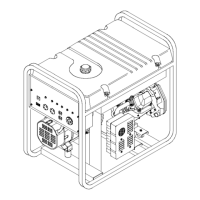

Figure 51. Checking Ignition Spark

Figure 52. Checking Engine Miss

To determine if an engine miss is ignition related, connect the

spark tester in series with the spark plug wire and the spark

plug (Figure 51). Then, crank and start the engine. A spark

miss will be readily apparent. If spark jumps the spark tester

gap regularly but the engine miss continues, the problem is in

the spark plug or in the fuel system.

NOTE: A sheared flywheel key may change ignition

timing but sparking will still occur across the spark

tester gap.

Results

1. If no spark or very weak spark occurs, go to Test 79.

2. If sparking occurs but engine still won’t start, go to Test

65.

3. When checking for engine miss, if sparking occurs at

regular intervals but engine miss continues, go to Test 57.

4. When checking for engine miss, if a spark miss is readily

apparent, go to Test 67.

TEST 65 – CHECK SPARK PLUGS

Discussion

If the engine will not start and Test 64 indicated good ignition

spark, perhaps the spark plug(s) are fouled or otherwise

damaged. Engine miss may also be caused by defective spark

plug(s).

Procedure

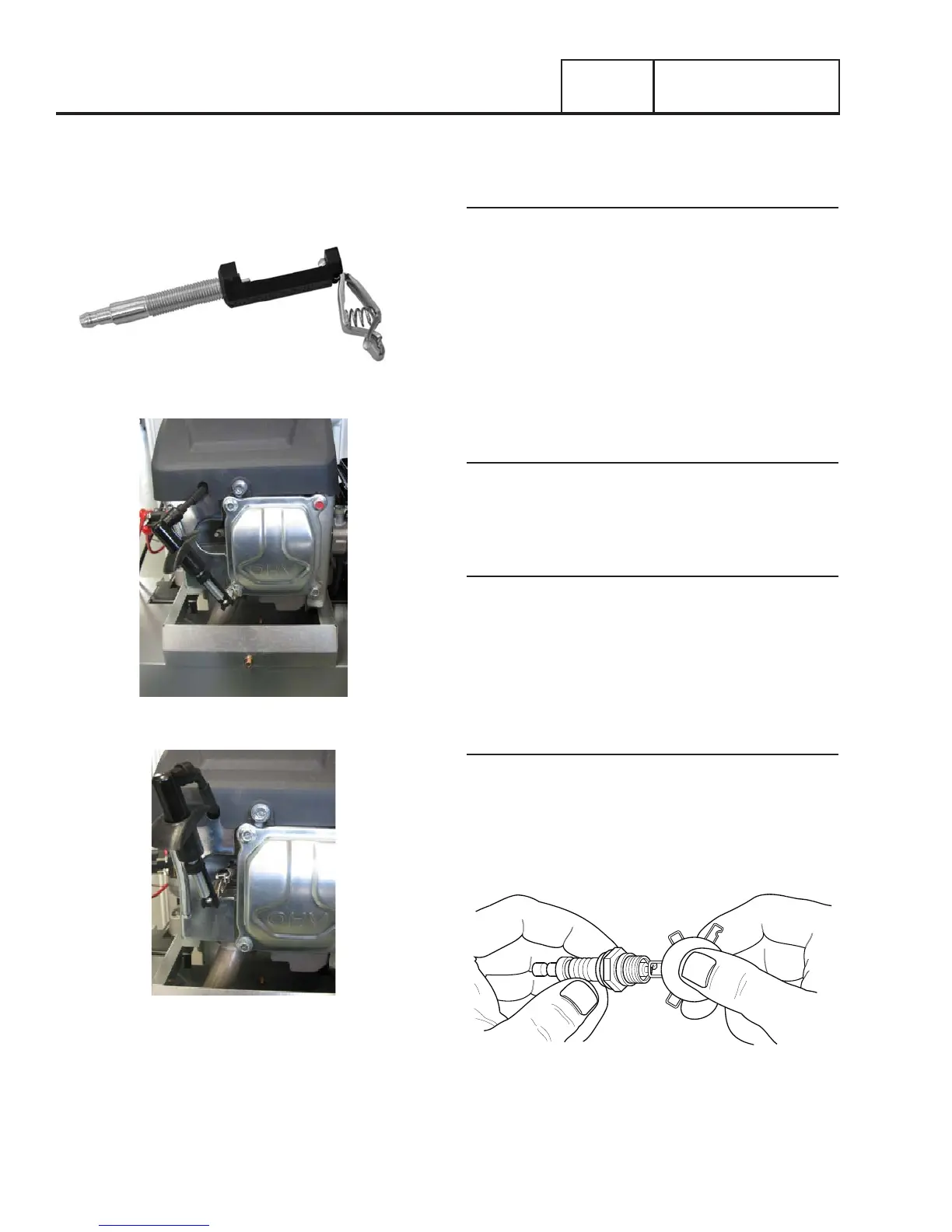

1. Remove spark plugs and clean with a penknife or use a

wire brush and solvent.

2. Replace any spark plug having burned electrodes or

cracked porcelain.

3. Set gap on new or used spark plugs to 0.76 mm (0.030

inch).

Results

1. Clean, re-gap or replace spark plugs as necessary.

2. If spark plugs are good, refer back to flow chart.

Figure 53. Checking Spark Plug Gap

Loading...

Loading...