PART 2

AC GENERATORS

Page 24

Section 2.1

Description and Components

INTRODUCTION

The alternator contained within the generator is a revolving field

(rotor) type with a stationary armature (stator), and excitation

to the field provided through brushes and slip rings (direct

excitation). The generator may be used to supply electrical

power for the operation of the 120 and/or 240 VAC, 1-phase,

60 Hz, AC loads.

ENGINE-GENERATOR DRIVE SYSTEM

The air-cooled engine is directly coupled to the rotor internally.

Both the engine and the rotor operate at 3600 rpm to provide a

60 HZ AC output.

ALTERNATOR ASSEMBLY

The standard alternator consists of three basic components;

a rotor, stator, and brush assembly. The rotor assembly

provides the magnetic field which will induce a voltage into the

stator assembly. The brush assembly provides the electrical

connection to the rotor, which allows for excitation voltage and

current to create the needed magnetic field.

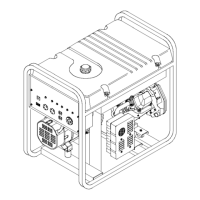

Rotor

Operating the 2-pole rotor at 3600 rpm will supply 60 HZ AC.

The term “2-pole” means the rotor has a single north and a

single south magnetic pole. Held in place with a single through

bolt, the tapered rotor shaft mounts to the tapered crankshaft

of the engine. As the rotor rotates its lines of magnetic flux cut

across the stator windings and induce a voltage into the stator

windings. The rotor shaft has a positive and negative slip ring,

with the positive slip ring nearest the lower bearing carrier. The

bearing is pressed onto the end of the rotor shaft.

Figure 14. Rotor

Stator

The stator houses a dual power winding and an excitation

winding. Coming from the stator there are eight stator leads as

shown in Figure 15.

An adapter molded into the engine block and a rear-bearing

carrier support the stator can. Four stator bolts connect the

rear bearing carrier and the stator can to the engine.

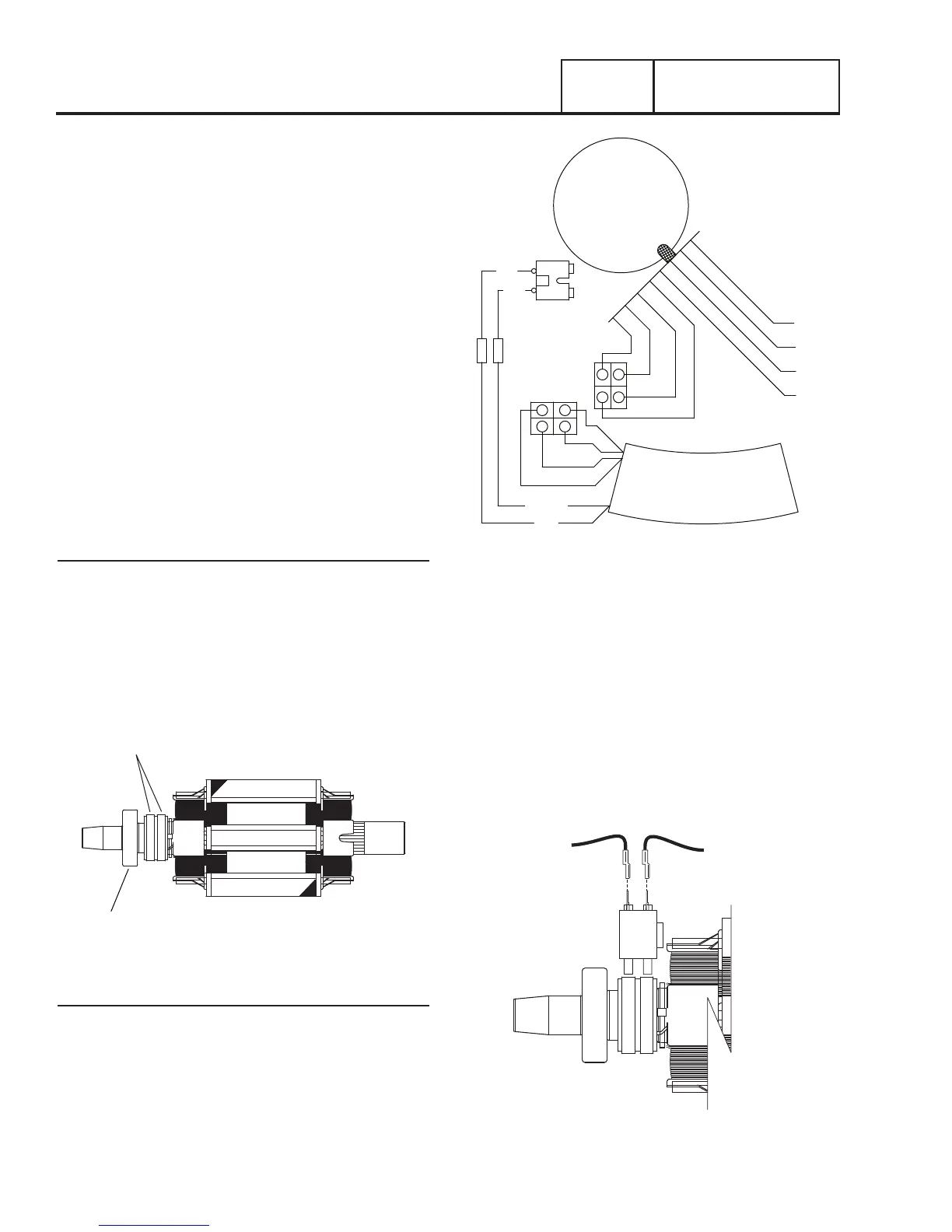

BLK

WHT

WHT

BLU

STATOR

RED

BLK

BA

RED(+)

WHT

AVR

C1

IC

IC

-

+

Figure 15. Stator Leads

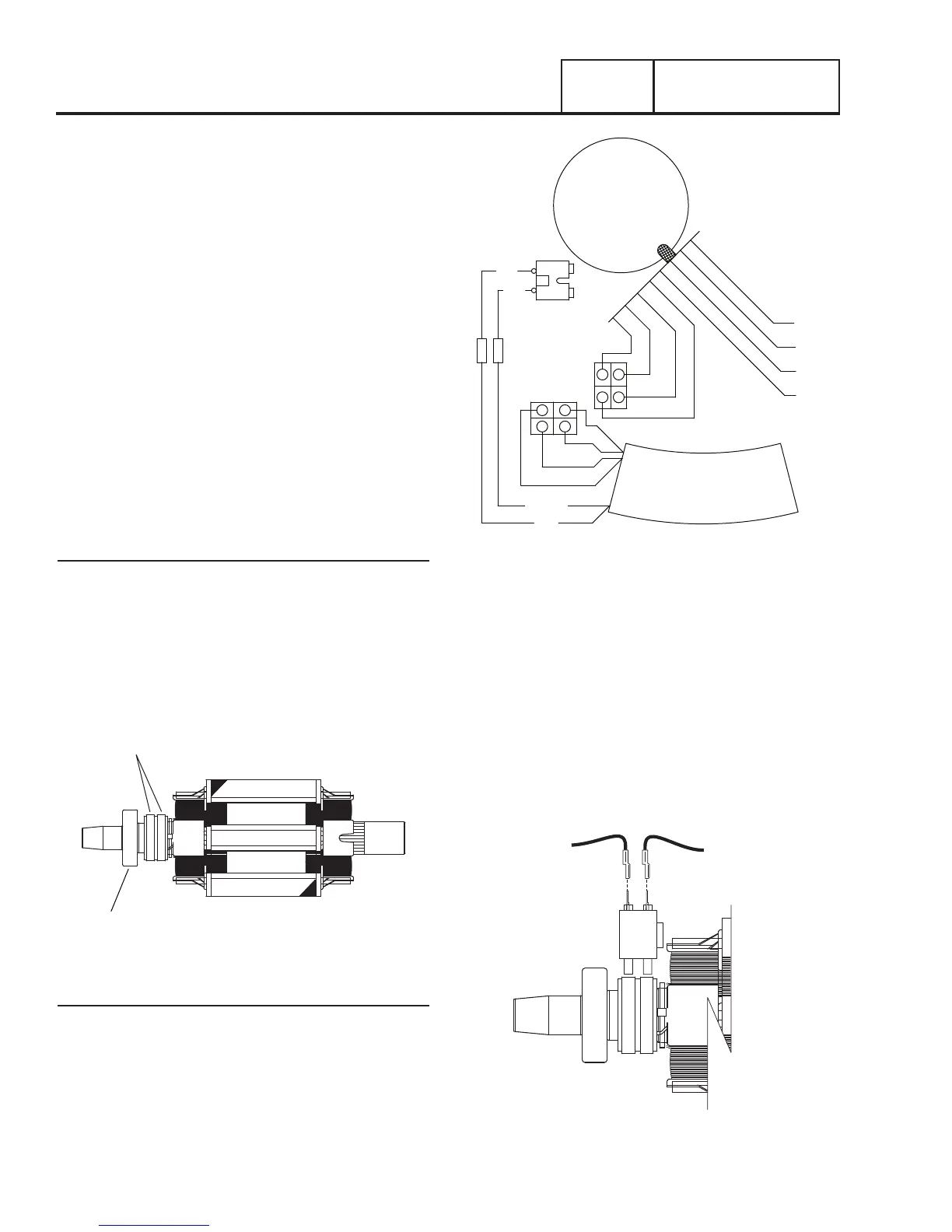

BRUSH HOLDER AND BRUSHES

Attached to the lower bearing carrier, the brush holder and

brushes allow for electrical connection to the rotor. Positive

and negative brushes are retained in the brush holder, with the

positive brush riding on the slip ring nearest the rotor bearing.

The Red wire connects to the positive brush and the Black

Wire to the negative brush. The rotor windings receive rectified

and regulated field excitation voltage (DC) through the Red and

Black Wires. The current flow creates a magnetic field around

the rotor having a flux concentration that is proportional to the

amount of current flow on the Red and Black Wires.

BLACK

RED

-

+

Figure 16. Brush Holder and Brushes

Loading...

Loading...