ENGINE/DC CONTROL

PART 4

Page 71

Section 4.5

Diagnostic Tests

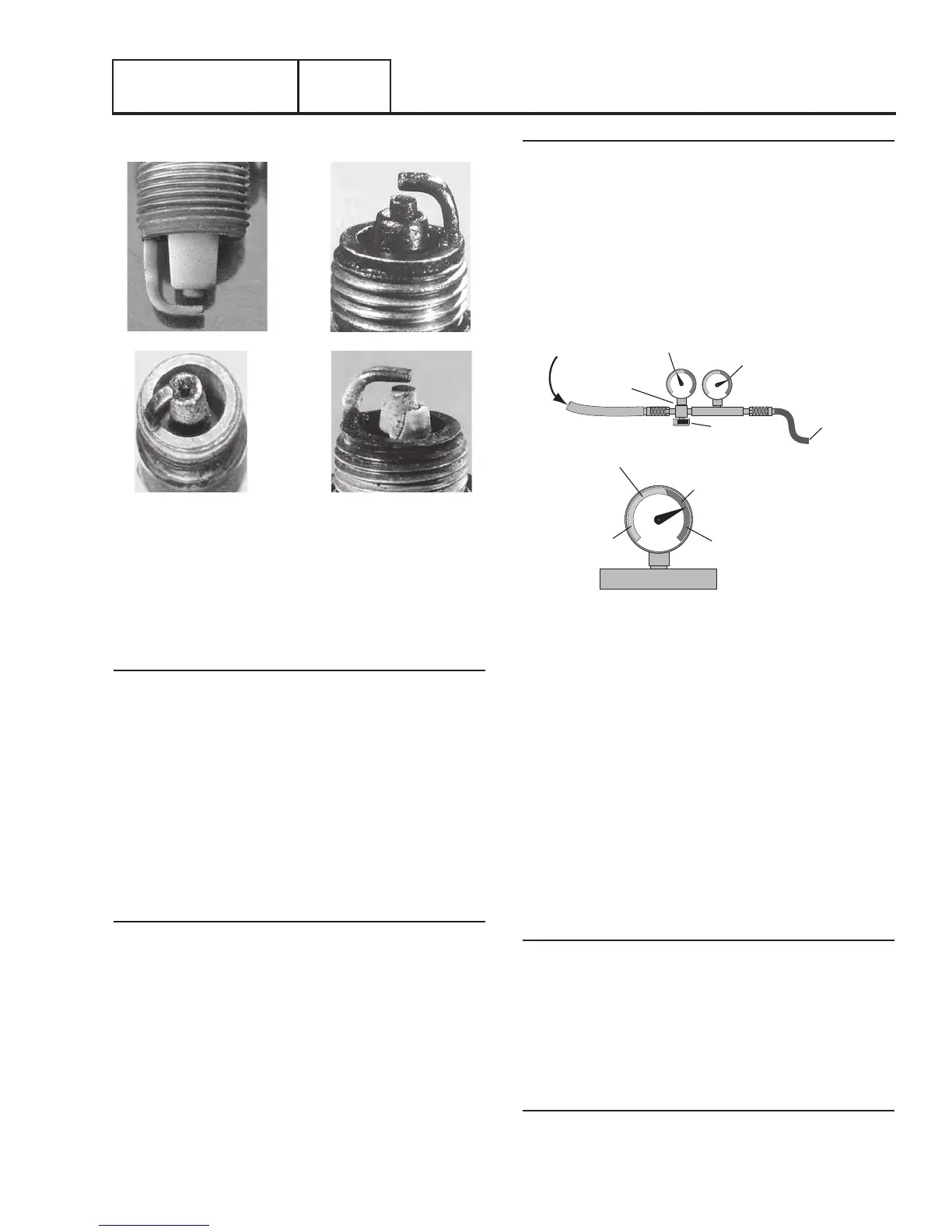

NORMAL MISFIRES

PRE-IGNITION DETONATION

Figure 54. Spark Plug Conditions

TEST 66 – CHECK ENGINE / CYLINDER LEAK

DOWN TEST / COMPRESSION TEST

Introduction

Performing the following test procedures will accurately

diagnose some of the most common problems:

•Will not start

•Lack of power

•Runs Rough

•Vibration

•Overheating

•High Oil Consumption

CYLINDER LEAK DOWN TEST

Discussion

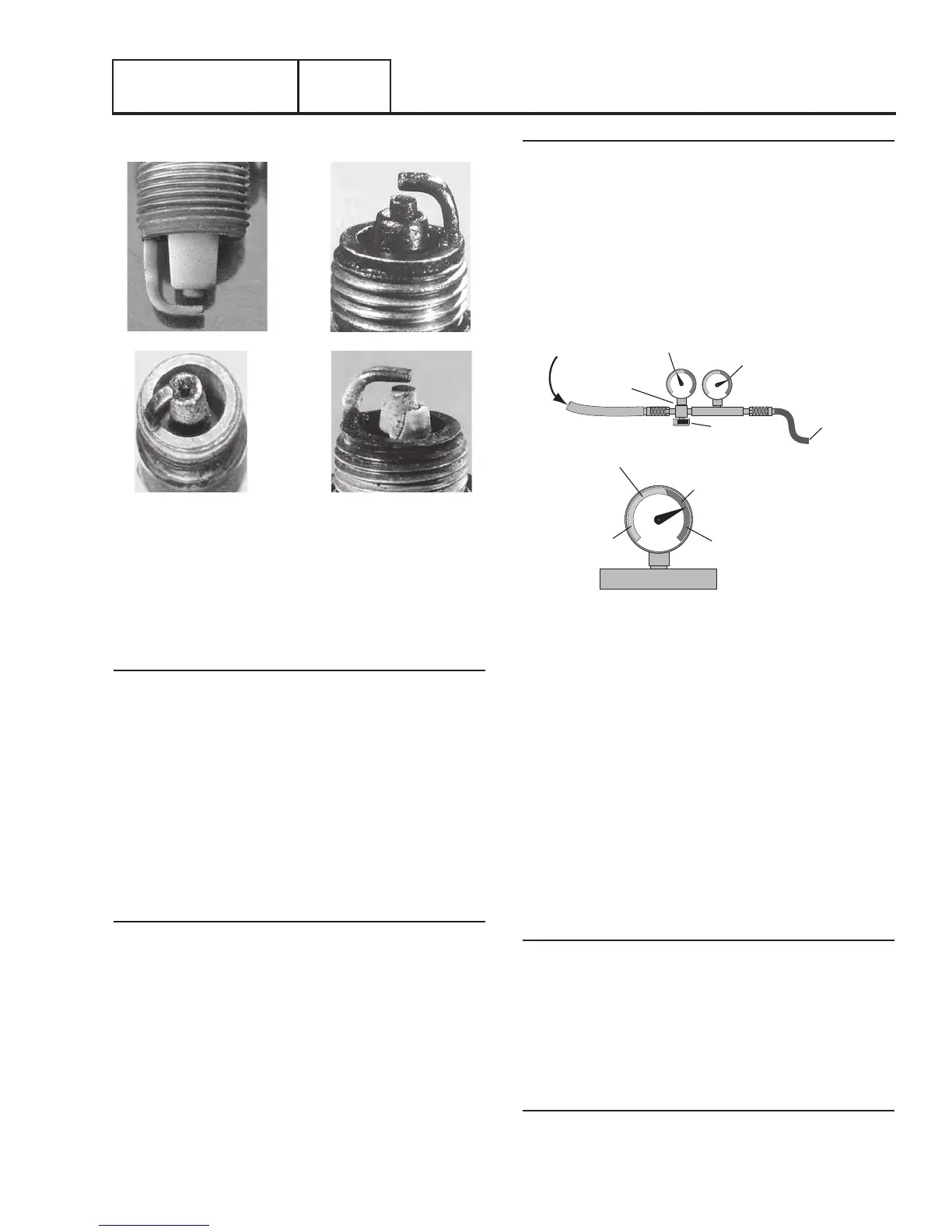

The Cylinder Leak Down Tester checks the sealing

(compression) ability of the engine by measuring air leakage

from the combustion chamber. Compression loss can present

many different symptoms. This test is designed to detect the

section of the engine where the fault lies before disassembling

the engine. Figure 55 represents a standard Tester available on

the market.

Note: Refer to Manufacturer's instructions for variations of

this procedure.

Procedure

1. Remove the spark plug from the front cylinder.

2. Gain access to the flywheel. Remove the valve cover.

3. Rotate the engine crankshaft until the piston reaches top

dead center (TDC). In this position, both the intake and

exhaust valves will be closed. If the engine is not properly

position at TDC the results of the test may be inaccurate

at diagnosing a problem.

INLET GUAGE

PRESSURE SET

POINT

RED RANGE INDICATES

UNACCEPTABLE LEAKAGE

GREEN RANGE INDICATES

ACCEPTABLE LEAKAGE

NEEDLE INDICATES

MINIMAL AIR LEAKAGE

AIR PRESSURE

REGULATOR

REGULATOR

ADJUSTMENT

KNOB

COMPRESSED

AIR IN

OUTLET GUAGE

PRESSURE

TO SPARK

PLUG HOLE

OUTLET

GUAGE

0

0

0

Figure 55. Cylinder Leakdown Tester

4. Lock the flywheel at top dead center.

5. Attach cylinder leak down tester adapter to spark plug

hole.

6. Connect an air source of 90 PSI to the cylinder leak down

tester.

7. Adjust the regulated pressure on the gauge to 80 PSI.

8. Read the right hand gauge on the tester for cylinder

pressure. A leakage of 20 percent is normally acceptable.

Use good judgment, and listen for air escaping at the

carburetor (air intake), the exhaust, and the crankcase

breather. This will determine where the fault lies.

9. Repeat Step 1 through 8 on remaining cylinder.

Results

•Air escapes at the carburetor (air intake)– check intake valve

•Air escapes through the exhaust – check exhaust valve

•Air escapes through the breather – check piston rings

•Air escapes from the cylinder head – the head gasket should

be replaced.

CHECK COMPRESSION

Discussion

Lost or reduced engine compression can result in a failure of

the engine to start, or a rough operation. One or more of the

following will usually cause loss of compression:

Loading...

Loading...