PART 4

ENGINE/DC CONTROL

Page 74

Section 4.5

Diagnostic Tests

Testing High Oil Temperature Switch

6. Remove the High Oil Temperature Switch.

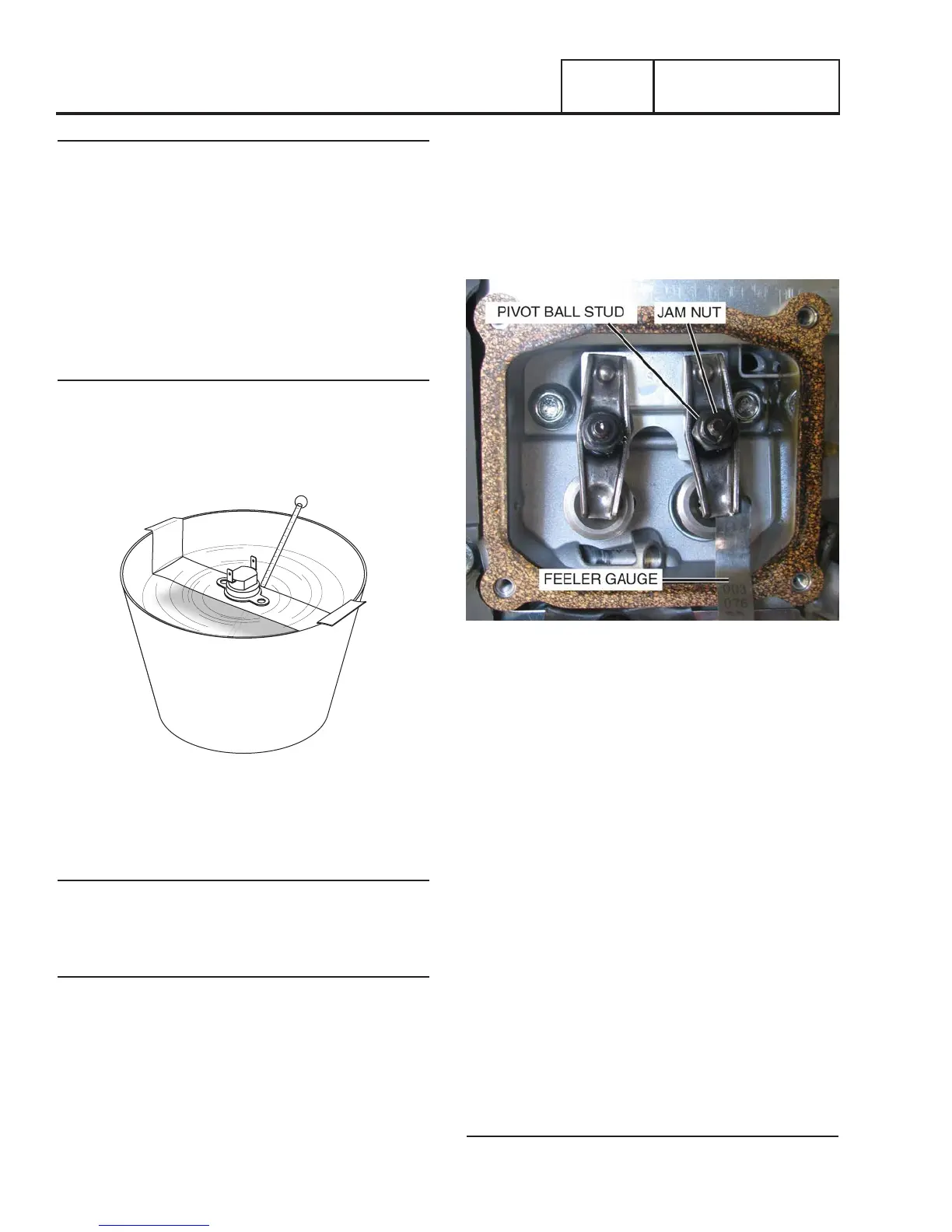

7. Immerse the sensing tip of the switch in oil as shown in

Figure 58, along with a suitable thermometer.

8. Set a VOM to measure resistance. Then, connect the VOM

test leads across the switch terminal and the switch body.

The meter should read INFINITY.

9. Heat the oil in the container. When the thermometer reads

approximately 283°-305° F. (139°-151° C.), the VOM

should indicate CONTINUITY.

Results

1. If the switch fails Step 4, or Steps 8-9, replace the switch.

2. If INFINITY was NOT measured in Step 5, repair or

replace Wire 85 between the controller and the High Oil

Temperature Switch.

Figure 58. Testing the Oil Temperature Switch

TEST 70 – CHECK AND ADJUST VALVES

Discussion

Improperly adjusted valves can cause various engine related

problems including, but not limited to, hard starting, rough

running and lack of power.

Procedure

1. The engine should be cool before checking. If valve

clearance is 0.006"-0.008" (0.15-0.20mm), adjustment is

not needed.

2. Remove spark plug wire and position wire away from

plug.

3. Remove spark plug.

4. Make sure the piston is at Top Dead Center (TDC) of

its compression stroke (both valves closed). To get the

piston at TDC, remove the intake screen at the top of the

engine to gain access to the flywheel nut. Use a large

socket and socket wrench to rotate the nut and hence the

engine in a clockwise direction. While watching the piston

through the spark plug hole. The piston should move up

and down. The piston is at TDC when it is at its highest

point of travel.

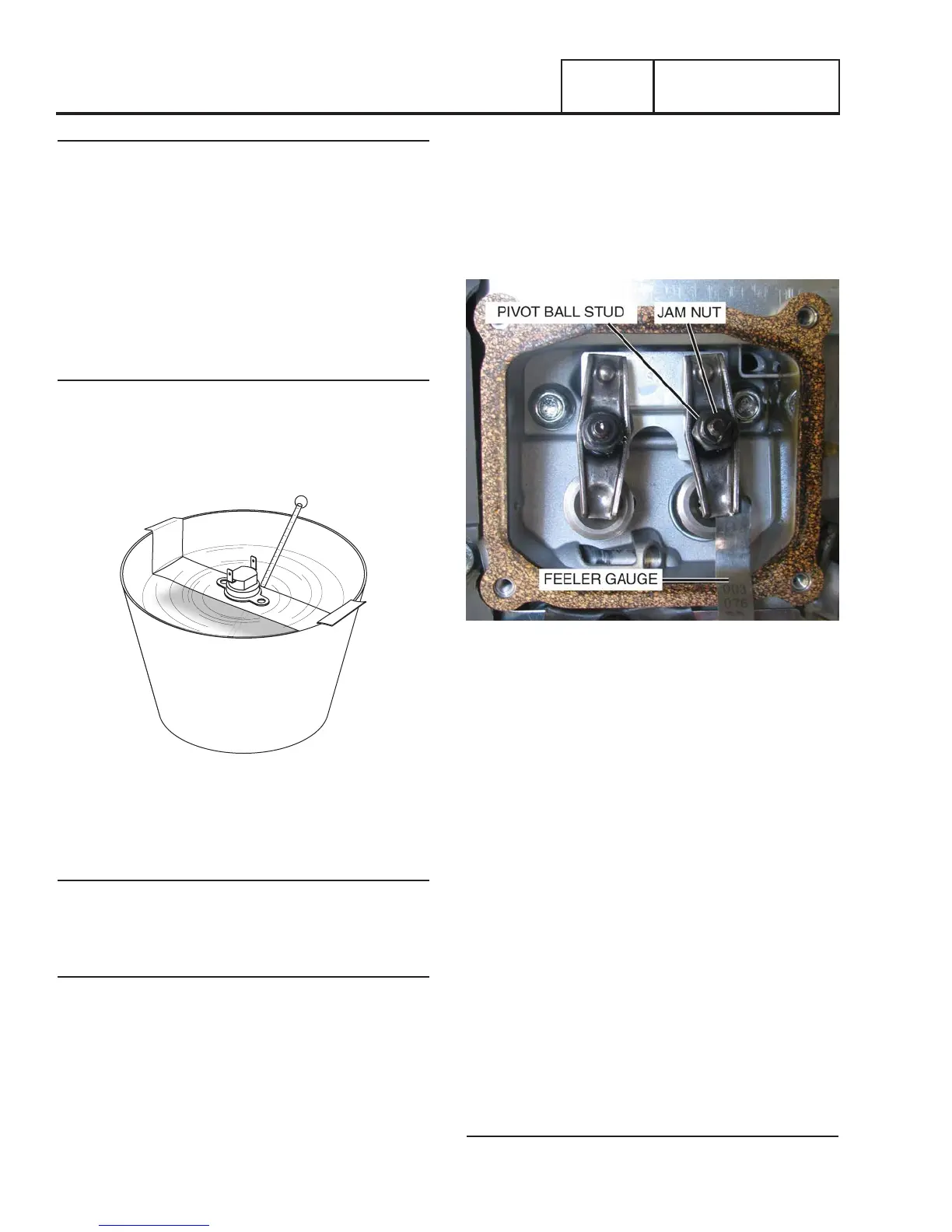

Figure 59. Valve Train

5. Remove the four screws attaching the valve cover.

6. Loosen the rocker jam nut. Use a wrench to turn the pivot

ball stud while checking clearance between the rocker

arm and the valve stem with a feeler gauge. Correct

clearance is:

Intake — 0.005-0.007 inch (0.13-0.17 mm)

Exhaust — 0.007-0.009 inch (0.18-0.22 mm)

NOTE: Hold the rocker arm jam nut in place as the pivot

ball stud is turned.

7. When valve clearance is correct, tighten the rocker arm

jam nut. Tighten the jam nut to 70 to 106 in-lbs. torque.

After tightening the jam nut, recheck valve clearance to

make sure it did not change.

8. Install new valve cover gasket.

9. Re-attach the valve cover.

NOTE: Start all four screws before tightening or it will not

be possible to get all the screws in place. Make sure the

valve cover gasket is in place.

10. Install spark plug.

11. Re-attach the spark plug wire to the spark plug.

Results

Adjust valve clearance as necessary, then retest.

Loading...

Loading...