PART 4

ENGINE/DC CONTROL

Page 64

Section 4.5

Diagnostic Tests

Procedure

A. Inspect Battery Cables:

1. Visually inspect battery cables and battery posts.

2. If cable clamps or terminals are corroded, clean away all

corrosion.

3. Install battery cables, making sure all cable clamps are

tight. The red battery cable from the starter contactor (SC)

must be securely attached to the positive (+) battery post;

the black cable from the frame ground stud must be tightly

attached to the negative (-) battery post.

4. Disconnect both negative and positive cables.

*Note: Disconnect negative battery cable first.

5. Using a DC Volt meter, measure DC volts on the battery.

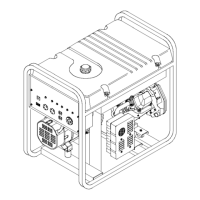

B. Perform a load test on the Battery:

(Maintenance Free Battery)

1. Using a lead acid battery load tester test the load

capability of the battery.

2. Follow the load tester’s manufacturer’s instructions carefully.

Figure 37. A Typical Battery Load Tester

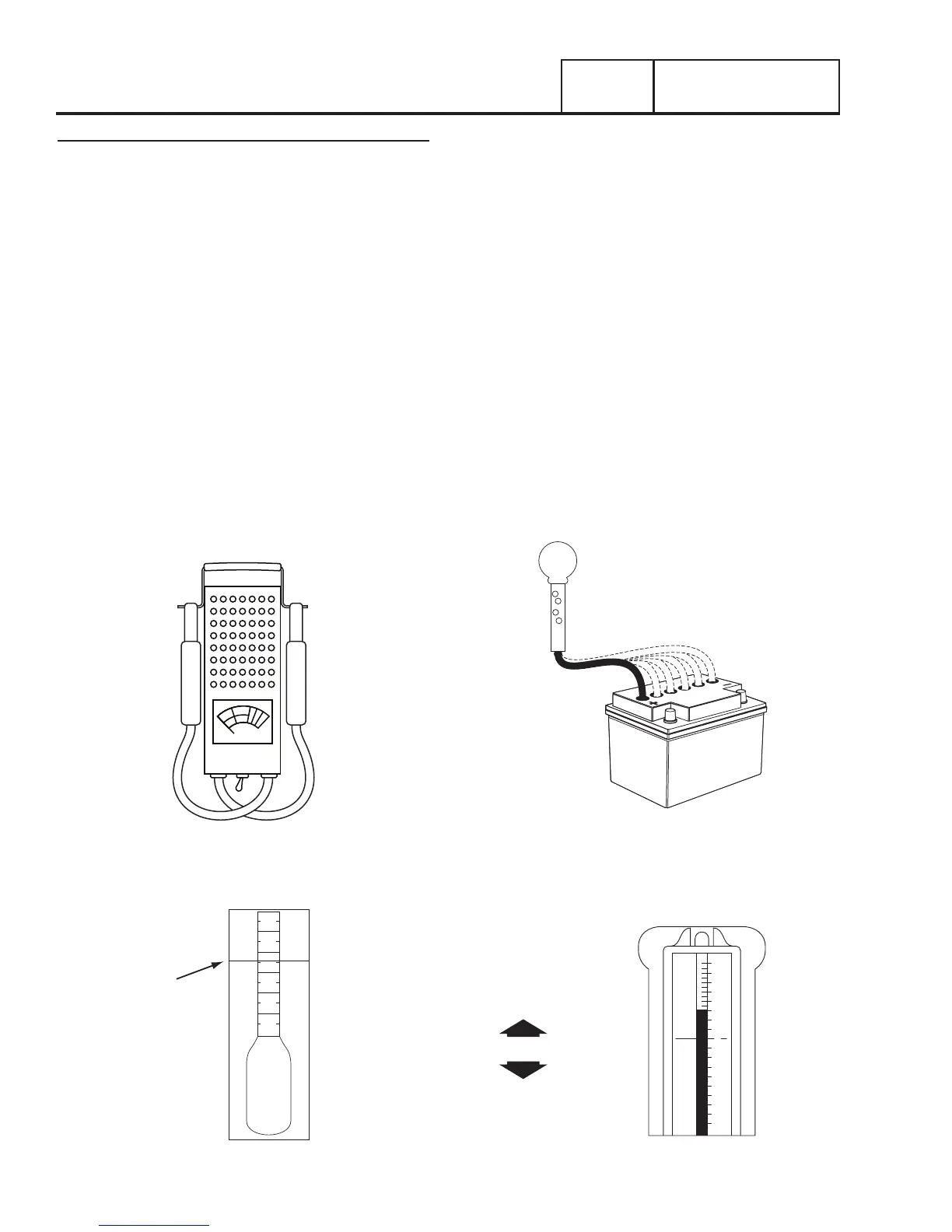

C. Test Battery State of Charge:

(Non-Maintenance Free Battery)

1. Use an automotive type battery hydrometer to test

battery state of charge.

2. Follow the hydrometer manufacturer’s instructions

carefully. Read the specific gravity of the electrolyte fluid

in all battery cells.

3. If cells are low, distilled water can be added to refill cell

compartment.

4. If the hydrometer does not have a “percentage of charge”

scale, compare the reading obtained to the following:

a. An average reading of 1.260 indicates the battery is

100% charged.

b. An average reading of 1.230 means the battery is 75%

charged.

c. An average reading of 1.200 means the battery is 50%

charged.

d. An average reading of 1.170 indicates the battery is

25% charged.

CHECK EACH CELL

AFTER CHARGING

USE A TEMPERATURE

COMPENSATED

HYDROMETER

Figure 38. Using a Battery Hydrometer

LIQUID

LEVEL

1220

1230

1240

1250

1260

1270

80°

0

4

8

12

16

20

24

28

32

4

8

12

16

20

24

28

32

26.6°

Cell # Specific Gravity

1 1.255

2 1.260

3 1.235

4 1.250

5 1.240

6 1.225

HIGH READING

LOW READING

35 POINTS DIFFERENCE

Figure 39. Reading a Battery Hydrometer

Loading...

Loading...