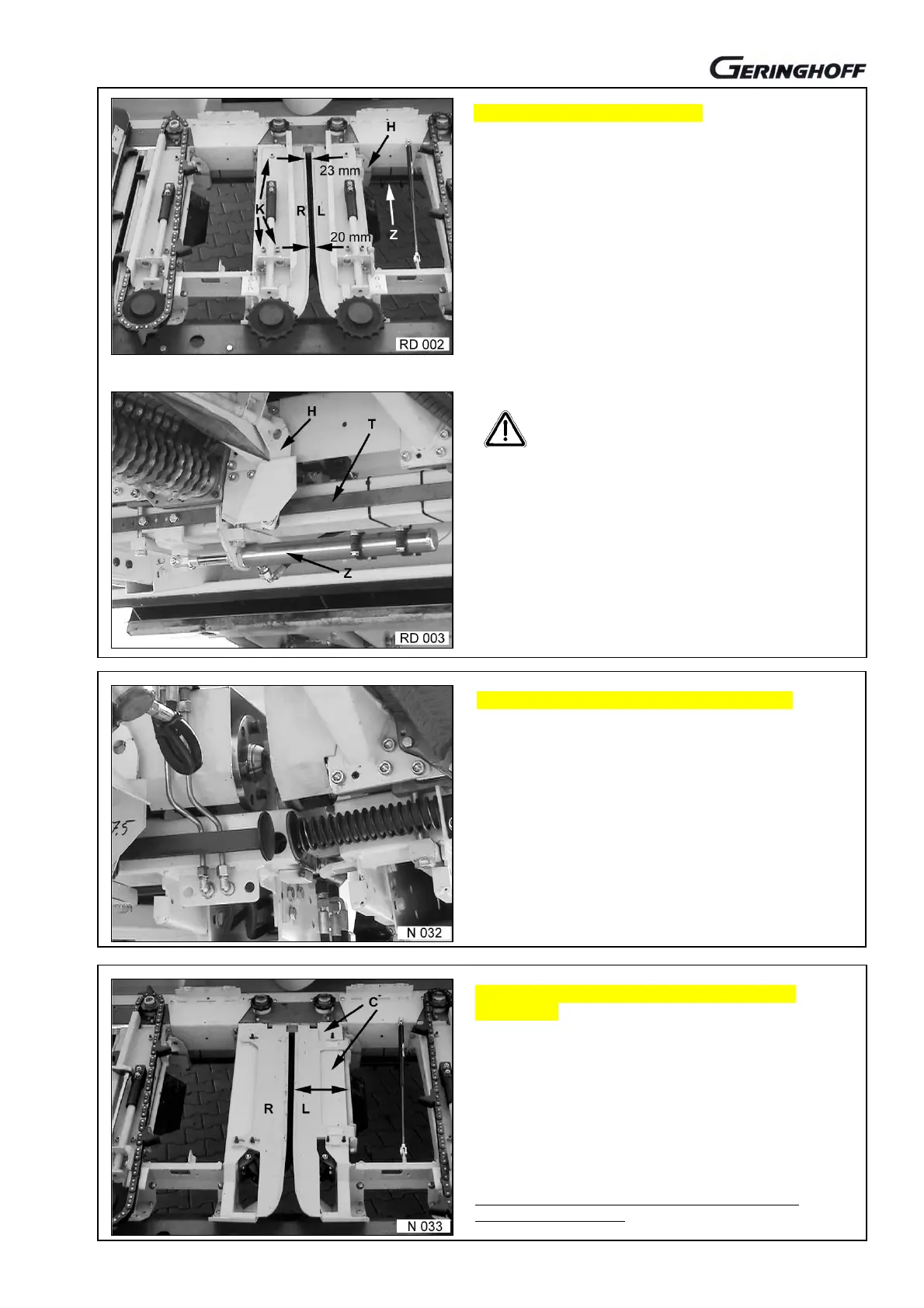

Stripping plate adjustment

09 / 480

Function and basic adjustment

The basic front adjustment is 20 mm and the rear one

23 mm in position „ narrow “. That means, the stripping

plates are pushed together as far as possible.

The wedge-shaped adjustment is of essence for the

function of the header.

These values are set via the screwed down stripping plate

(R) and the screws (K).

For the harvest, the stripping plates are operated

hydraulically via „reel to lift and lower“.

The average corn ear diameter is important for the setting

of the stripping plate distance. For this reason, the plates

for the harvest works should be opened as far as possible,

ust as far as to prevent cob losses.

Prior to checking, Diesel motor

to turn off!

Header to secure against unwanted

lowering!

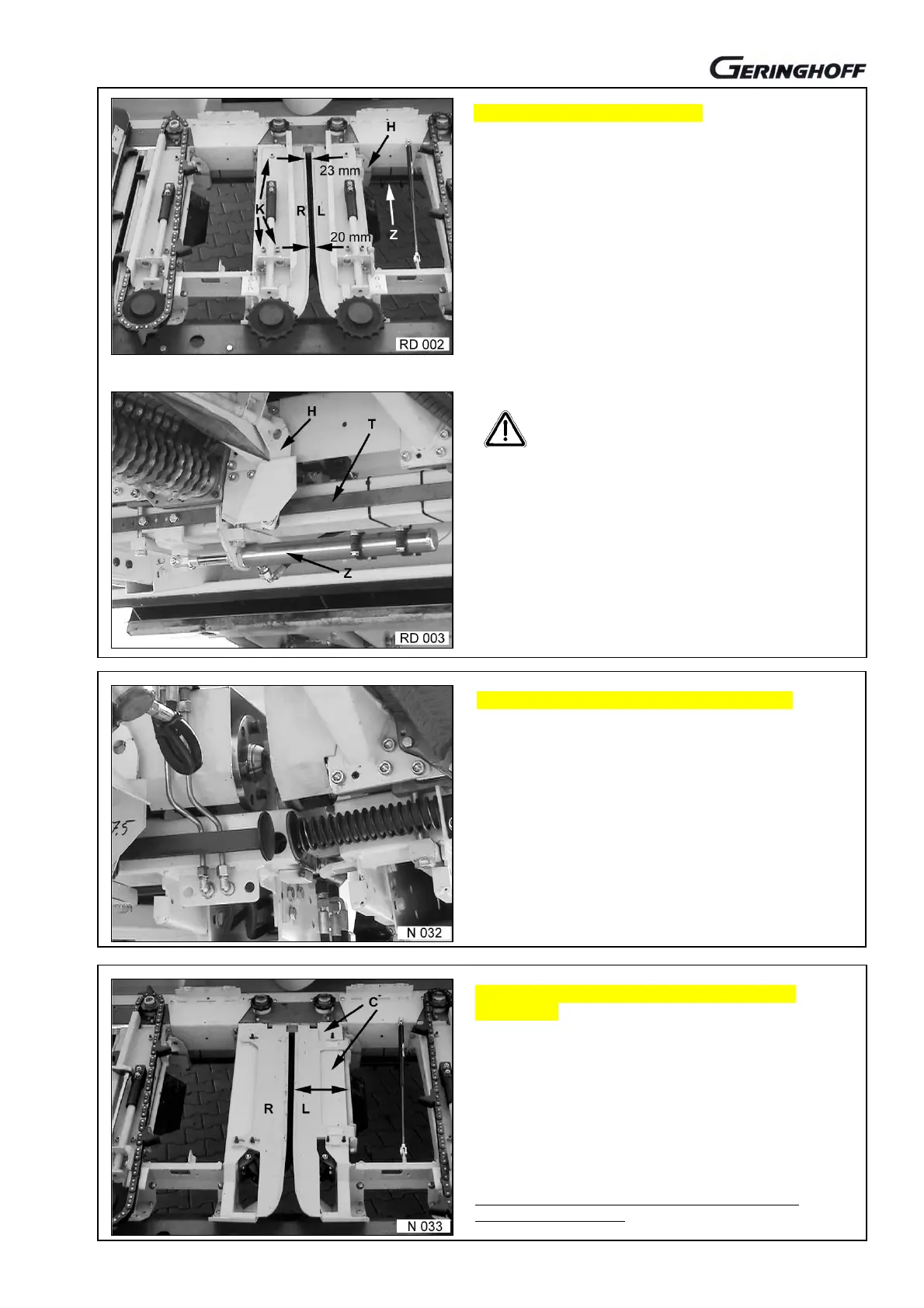

Via the shifting cylinder (Z) the left stripping plates are

opened by the sliding bar (T) and lever (H). The plates are

closed again by one or several restoring springs.

The regulation of the uniform setting of all stripping plates

on the different rows is made by shifting the levers (H) on

the sliding bar (T).

Before going to make a readjustment, it is recommended to

check the basic adjustment „in front 20 mm, rear 23 mm“.

Stripping plate adjustment folding headers

The function and layout is identical to the unfolding

machines.

The stripping plates on the folding parts are actuated via

the spring-loaded sliding bar contact. Additional, right and

left differently mounted restoring springs open the plates

on activation of the folding process.

Pressure plates should well overlap.

djustment and setting to be made in working position and

adequate locking only.

Maintenance and care of the stripping plate

adjustment

Impurities are not to exclude. For that reason, at least once

the day the stripping plates (L) to open and close several

times to assure the free floating and to remove impurities.

Joints to oil every 100 h. Restoring springs to clean.

Once finished the harvest works, bearing (C) of the

adjustable stripping plate (L) to clean and to protect

against corrosion using adequate means.

Check that the cut-off block is centrically arranged in

central working position.

Loading...

Loading...