Cross conveying auger/ Feeding

09 / 720

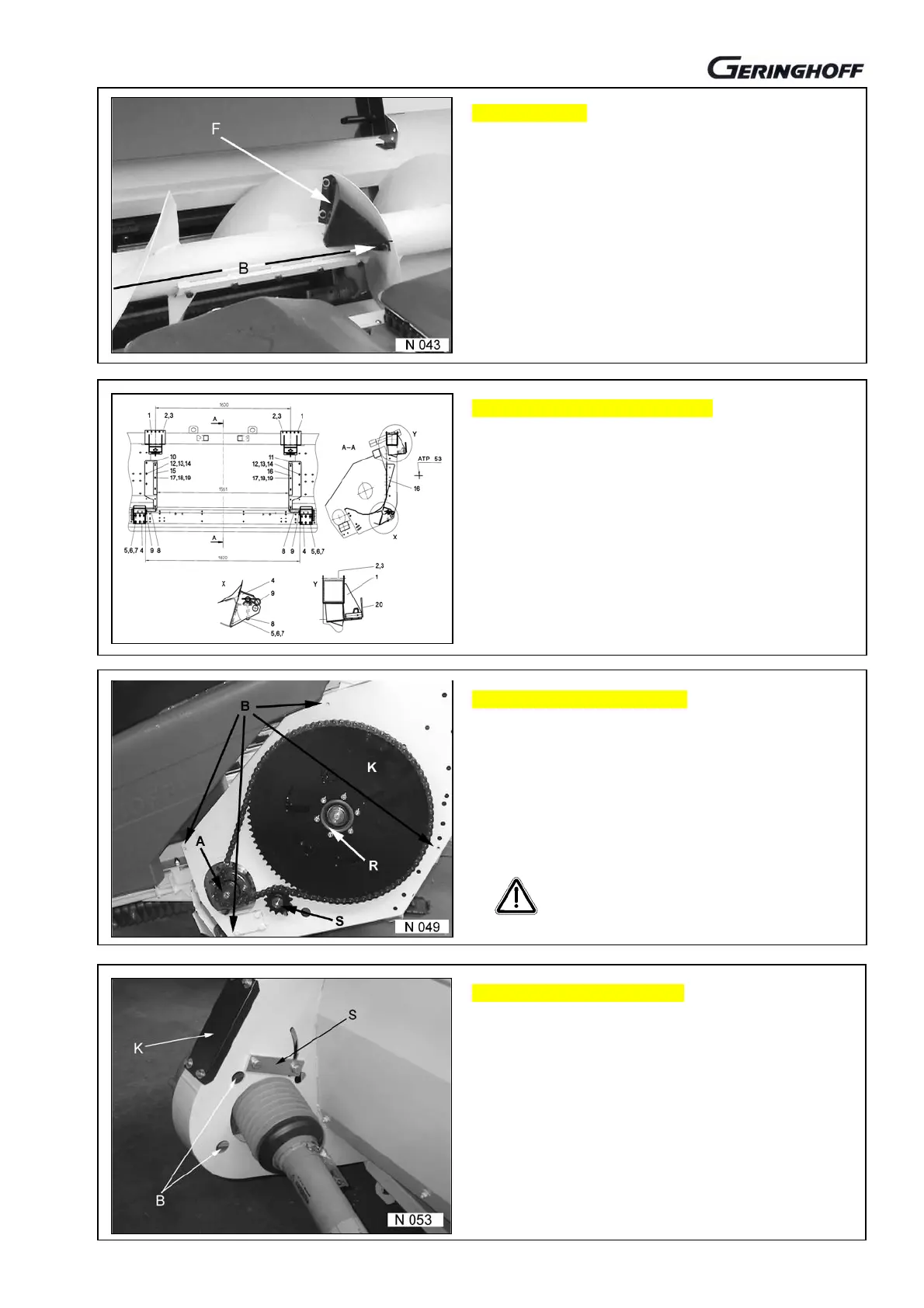

Conveying aids

The conveying aids (F) are mounted as standard on the

cross conveying auger.

On option, these conveying aids can be enclosed

unpacked and mounted on the site.

In the event of a not uniform feeding all over the combine

width, the conveying aid (size B) is to mount 40 mm

narrower than the inside gathering channel width is.

That means the size (B) must be 40 mm smaller than the

channel opening of the combine.

Feed opening of the corn header

Certain opening sizes of the header for all combine makes

and models are determined for the feeding to the gathering

channel of the combine.

The exact opening width to be learnt from the sketches in

the spare part catalogue from picture table 60/.. .

For standardization reasons, slight variations from the rated

size are allowed.

In particular when working on slopes a regular feeding is of

essence for the harvest material to be distributed evenly

within the machine.

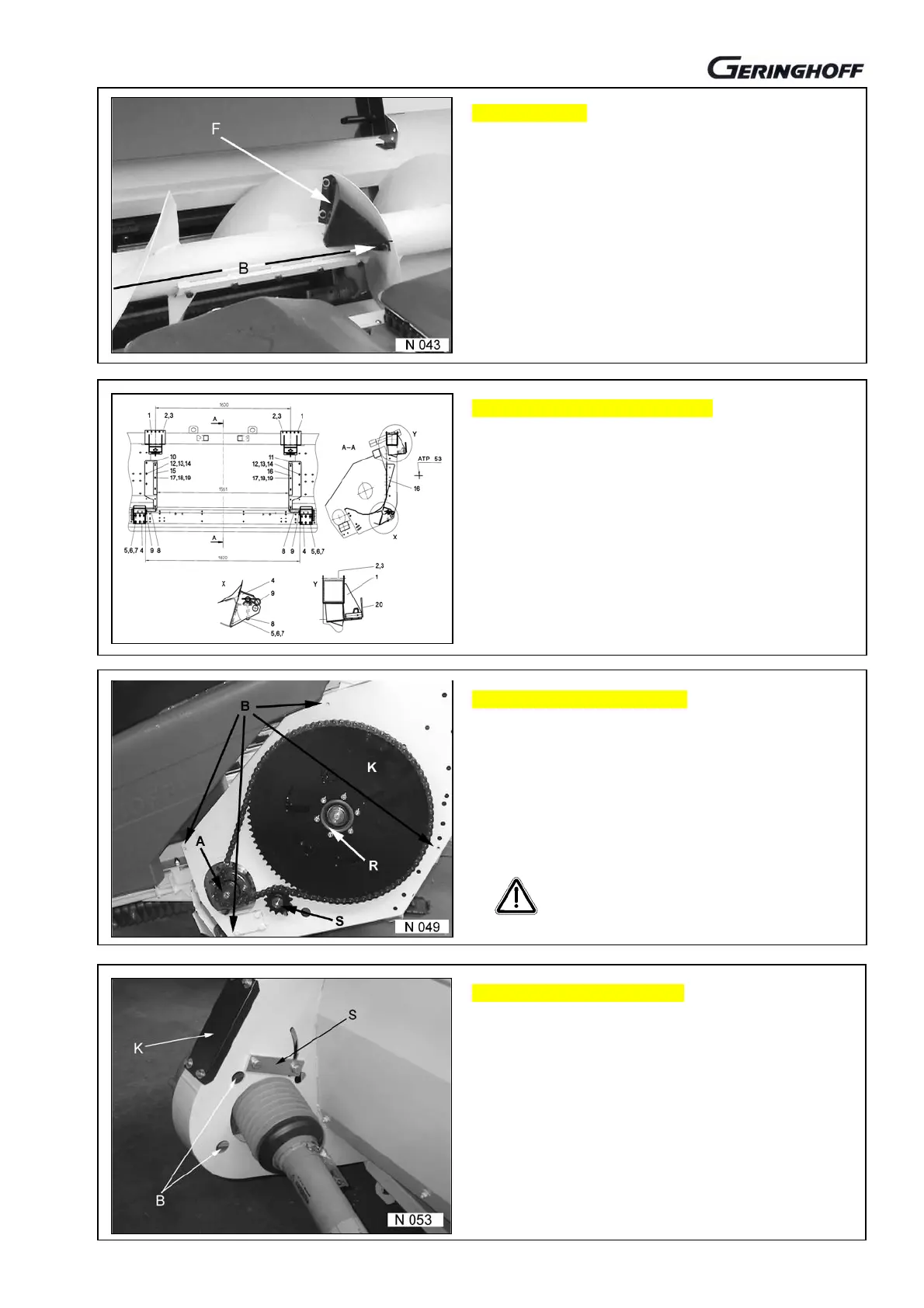

Auger drive up to 6 row units

The auger is driven from the side opposite to the main

drive. The speed is subject to the main shaft of the header

and thus preset.

Chain tension to check in regular intervals, if required, to

readjust via the idler (S).

Chain to oil in regular intervals.

Protection box to clean in regular intervals.

Corn header never to operate without

guards mounted and closed!

Auger drive from 8 row units

The auger is driven from the feed shaft of the contrate gear

transmission and is not subject to the speed of the header.

Maintenance and care of the chain drive to be made via the

flap (K)

The chain tension is adjusted by shifting the tension lever

(S) downwards.

ll bearings of the cross conveying auger are maintenance-

free.

The bores (B) serve to fasten the contrate gear

transmission.

Loading...

Loading...