Couplings between the row units

09 / 640

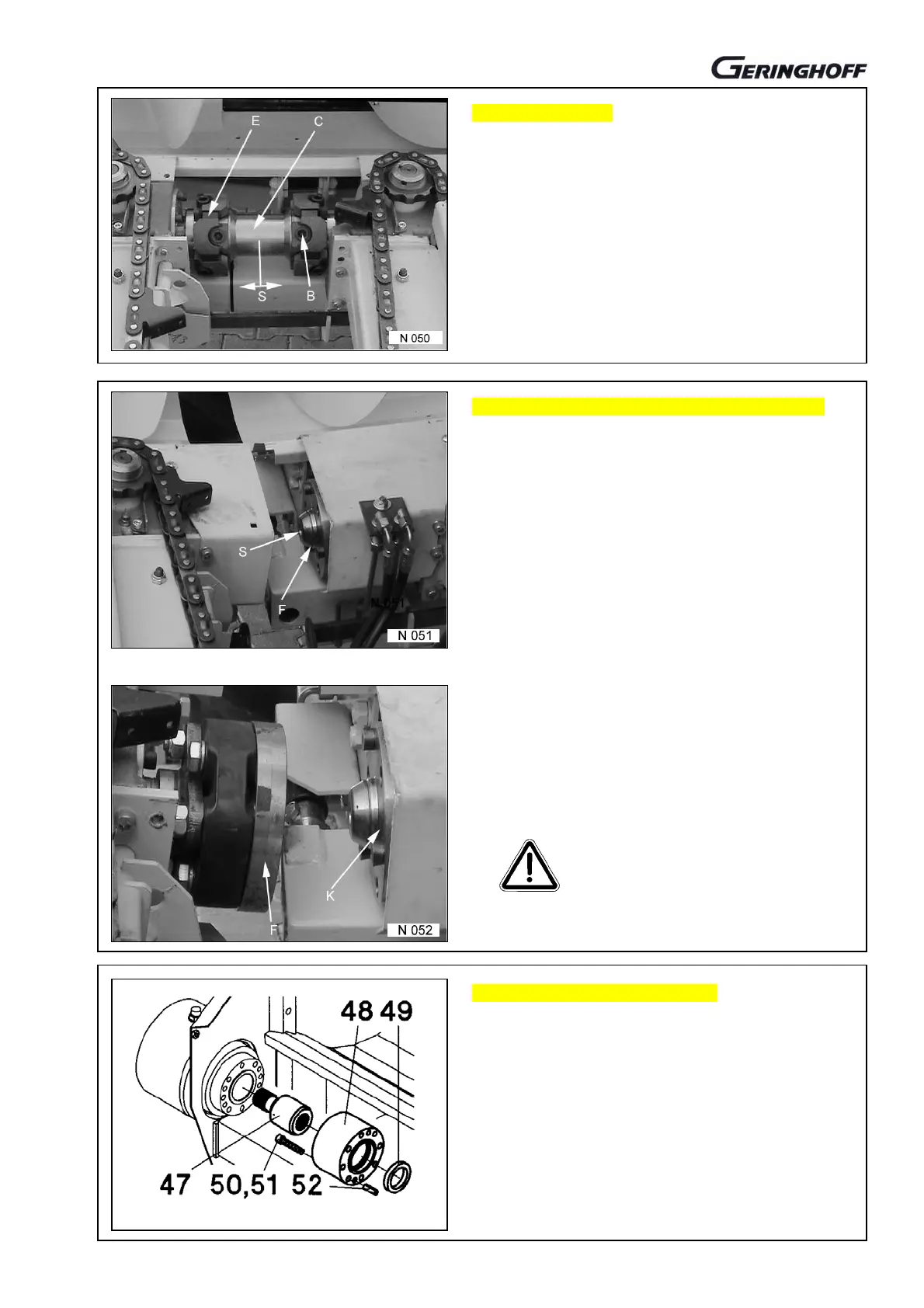

Centaflex-couplers

Centaflex-couplers (C) to be checked in regular intervals

for the state of the flexible elements (E) and engaging

dogs.

Worn parts to replace immediately.

xial clearance (S) of 2 mm for the center part (C)

absolutely to keep.

Hexagon socket screws (B) to tighten with 140 Nm.

Row unit drive connections on the folding parts

The axial movability of the coupling half (F) to be checked

in regular intervals by mounting lever to be pressed in.

If required, axial safety bolt (S) to unscrew, coupling half to

pull off, splined shaft section to clean and grease.

The parallel position of the cam plate (K) towards the

punched disk (F) to be checked in regular intervals with the

machine put out of operation and the coupler engaged.

Radial differences are to be compensated by

readjustments made on the pivot of the folding part

suspension.

Drive couplers to get engaged

only at minimum speeds.

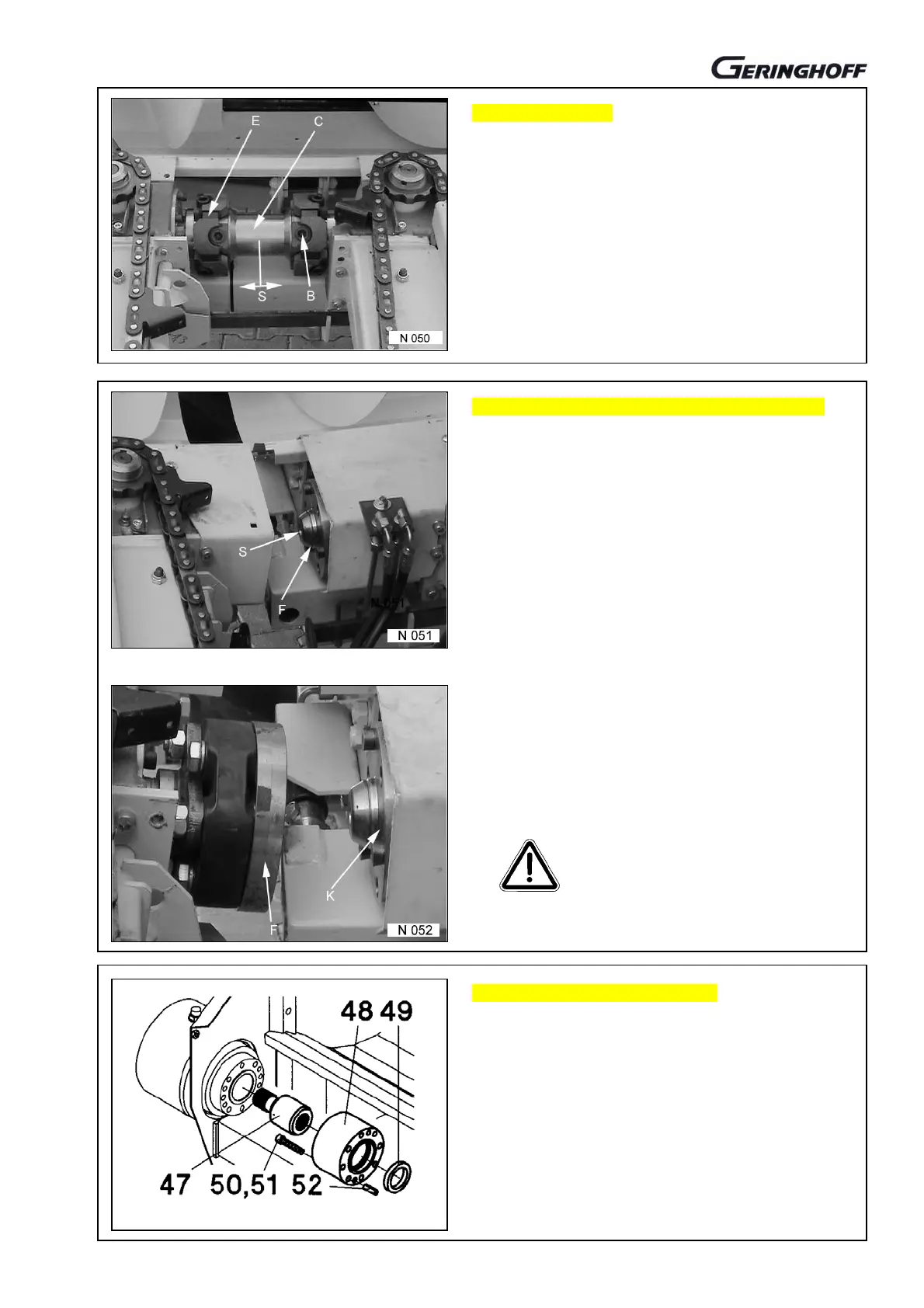

Corn header with shaft extension (optional)

Corn headers with certain row distances can be fitted with

a shaft extension on the drive side.

Flange (48) and intermediate shaft (47) are arranged

between angular gear and the row unit gear.

The intermediate shaft needs no maintenance at all.

Loading...

Loading...