Maintenance and care

10 / 300

Cleaning after the harvest season

Once finished quite a dry harvest season, a dry cleaning is

recommended using only compressed air.

If the machine was exposed to humidity with thus getting

strongly soiled, a high-pressure cleaner should be used.

First, the shields and gathering chains to take off and all

bearings lubricated.

Greasing points

The greasing points are located as follows: ( hours)

Stripping rows: on front bearing ( 15)

PTO-shafts: general (100)

PTO-shafts: tubes and sliders

(200)

Folding mechanisms: joints and pivots (100)

Shaft coupler: sliders / flange (200)

The brackets show the greasing intervals in hours.

fter each cleaning, the machine should be greased again

and put into operation for short time.

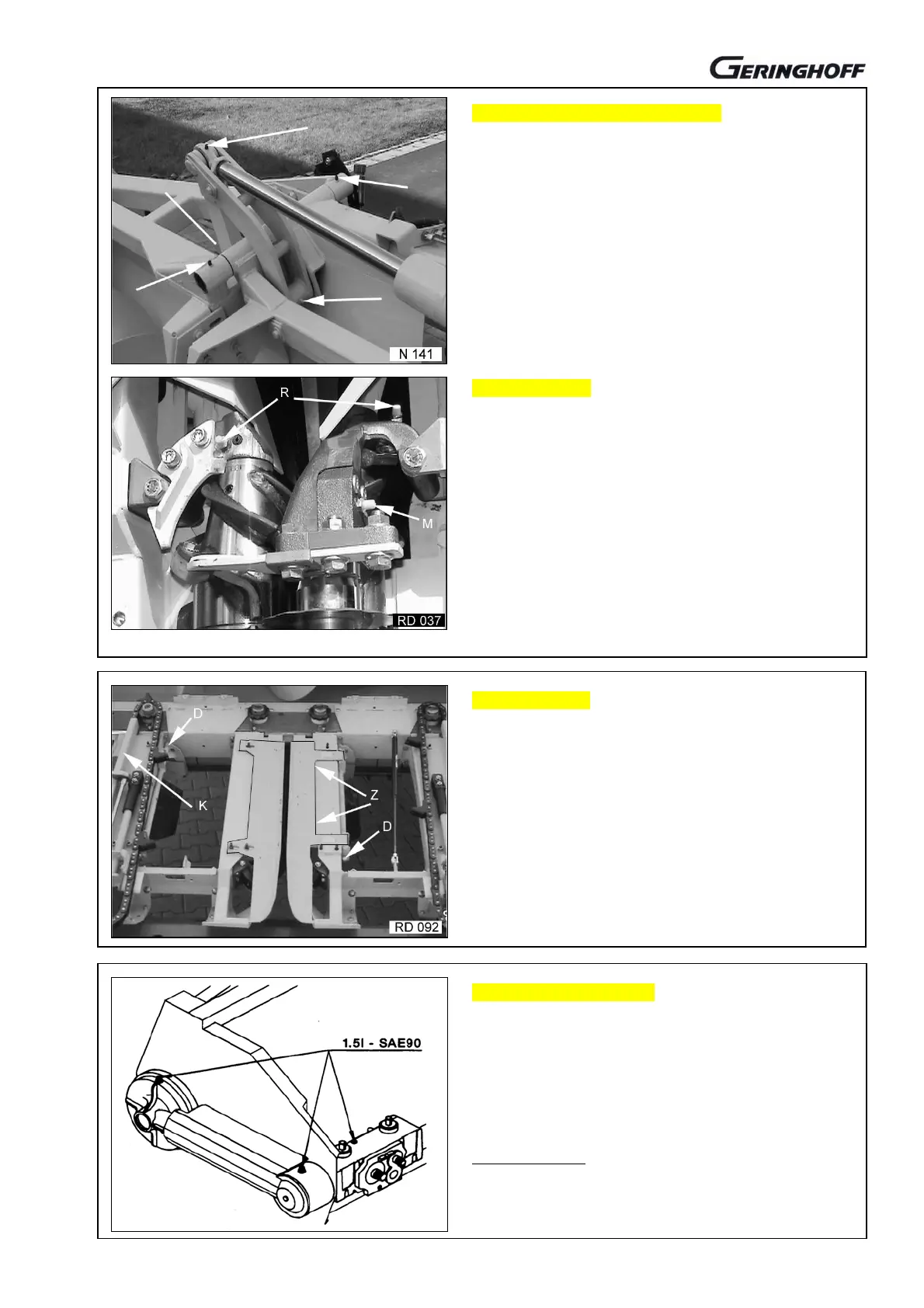

Stripping plates

When cleaning the machine, the stripping plates must be

moved quite often for removing dust and corn remainders

out of the pushing channels (Z).

If the machine is cleaned with water, the chain guides (K)

to remove and the pushing area (Z) of the stripping plates

to clean and protect against corrosion.

The pivots (D) should be oiled or greased.

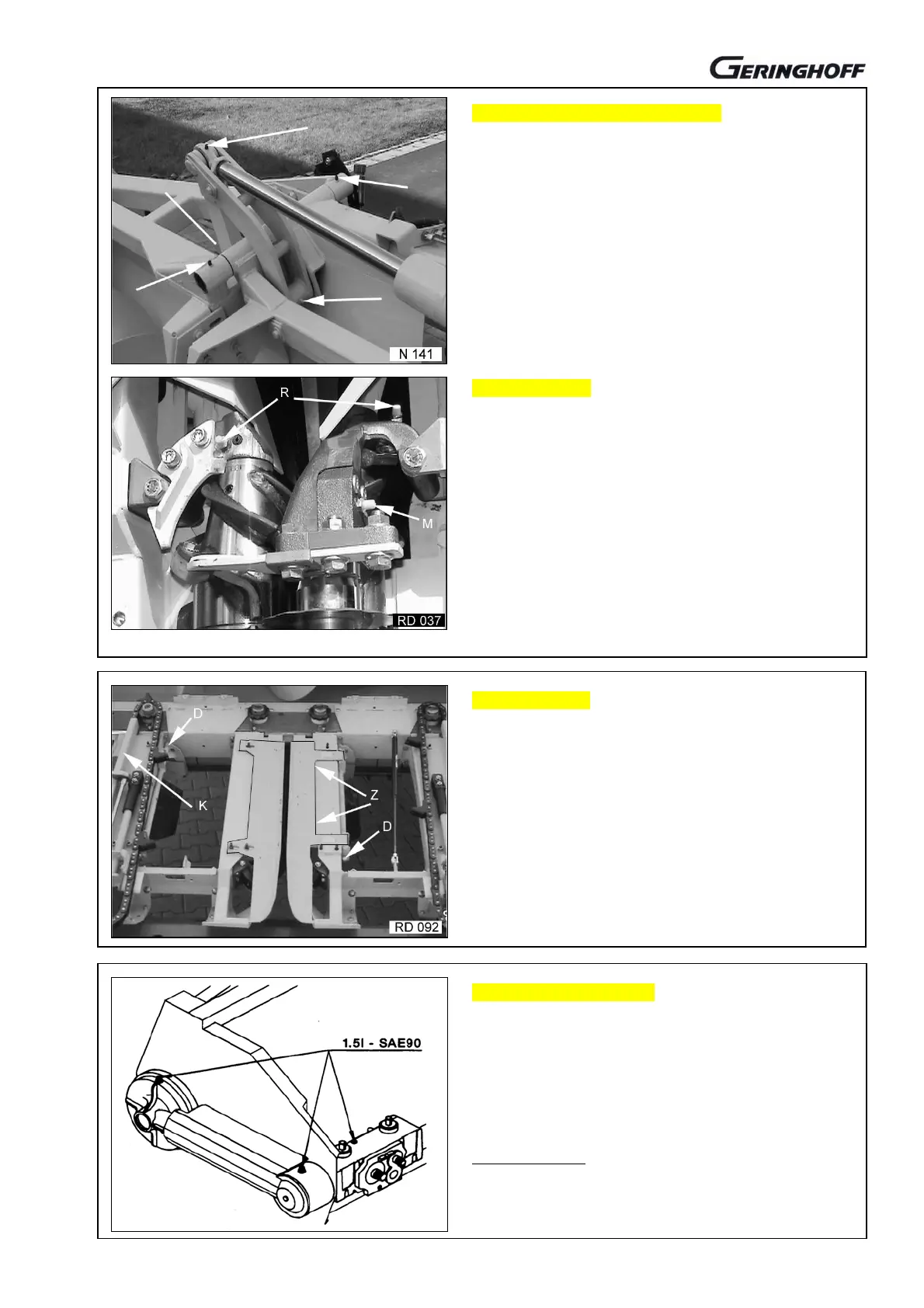

Gear (see also page 09 / 560)

Filling quantity: 1,5 l gear oil SAE 90 (commercial quality)

To fill up to the escape on gauge opening and/or according

to dip stick indicator.

Change intervals: 50 h from start-up, then once before

each harvest, but at latest after 200 h.

Oil drain plug (A) is fitted with magnet, which must be

cleaned on each oil change.

Oil level to check !

Prior to winterizing the header, vent screws on the folding

elements to be checked for tightness.

Loading...

Loading...