Row unit RD

10 / 210

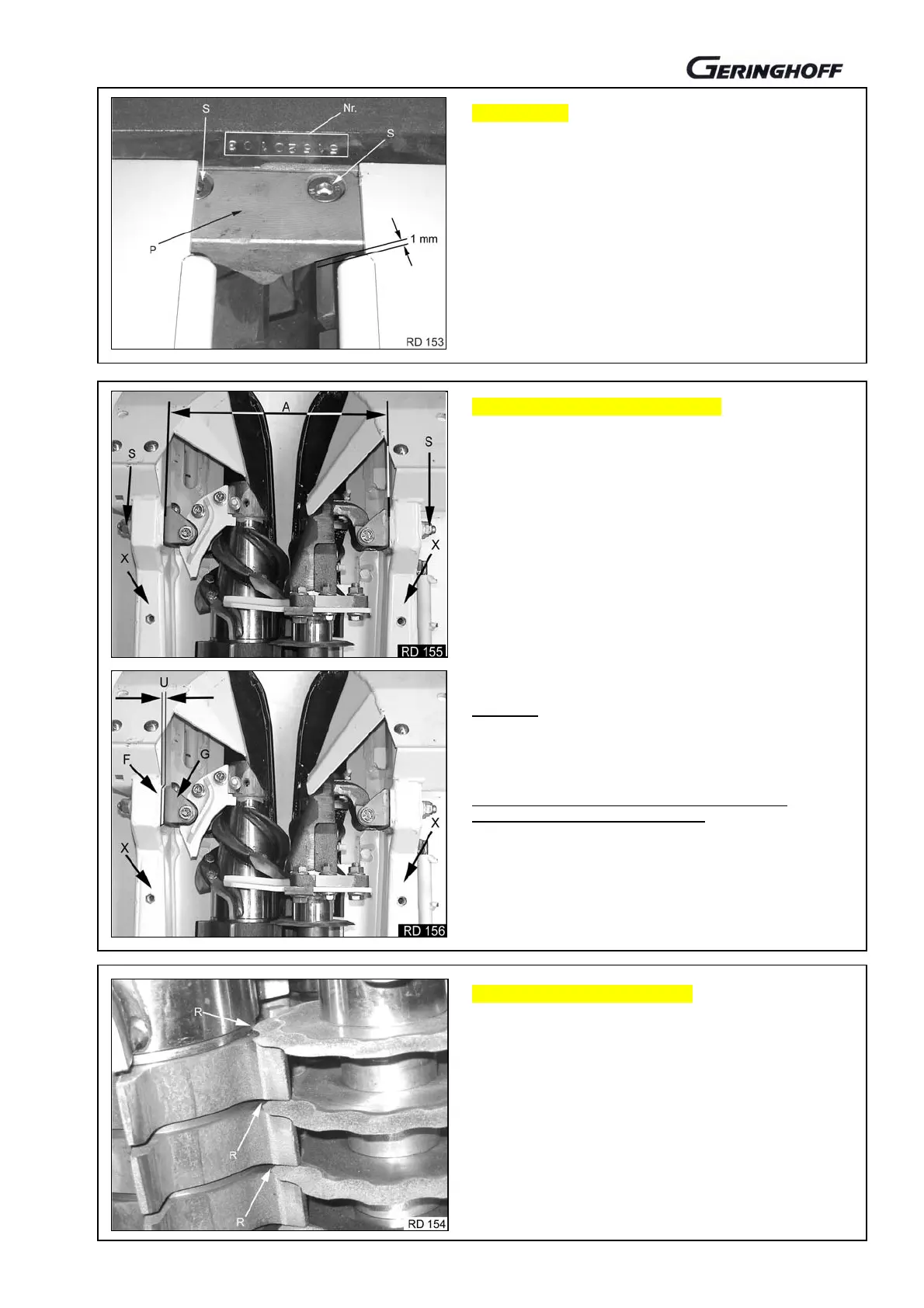

Cut-off block

The cut-off block (P) is mounted with screws (S) beneath

the stripping plates in front of the gearbox.

If required, the spacing (A) to the rotors (max. 1 mm) is to

be adjusted via spacers put between the cut-off block and

the row unit gear.

If the spacing is more than mm, in particular on humid

conditions, the rotor runs into the risk of blocking in this

area.

Note: The individual number of each row unit is indicated

on the pos. (no.).

Control dimension row unit frame

The correct frame carrier spacing (X) in the frontal zone (A)

is of essence for the function of the corn header.

This spacing can be changed by collisions. In particular on

the outer rows (right and left) the carrying arms may

become bent because there aren’t further rows for support.

In the event of a collision or when starting a faulty operation

of a row unit, the spacing (A) 317,5 which may vary +/- 0,5

mm, is to be checked. The variance mentioned is to be

strictly maintained.

To be able to isolate which carrying arm (X) is bent, the

screws (S) must be loosened at least once by hand without

any harvest material building up. The resultant gap (U)

indicates the bent side. Slight differences of up to 4 mm

can be compensated via slotted washers put between the

fork (G) and the area (F).

Attention!

If a spacer is mounted below the fork (G), the stripping

plate attached must be readjusted separately to

reestablish the basic setting (see page 09 / 480).

In the event of greater damage, the carrying arm in

question must be aligned or replaced!

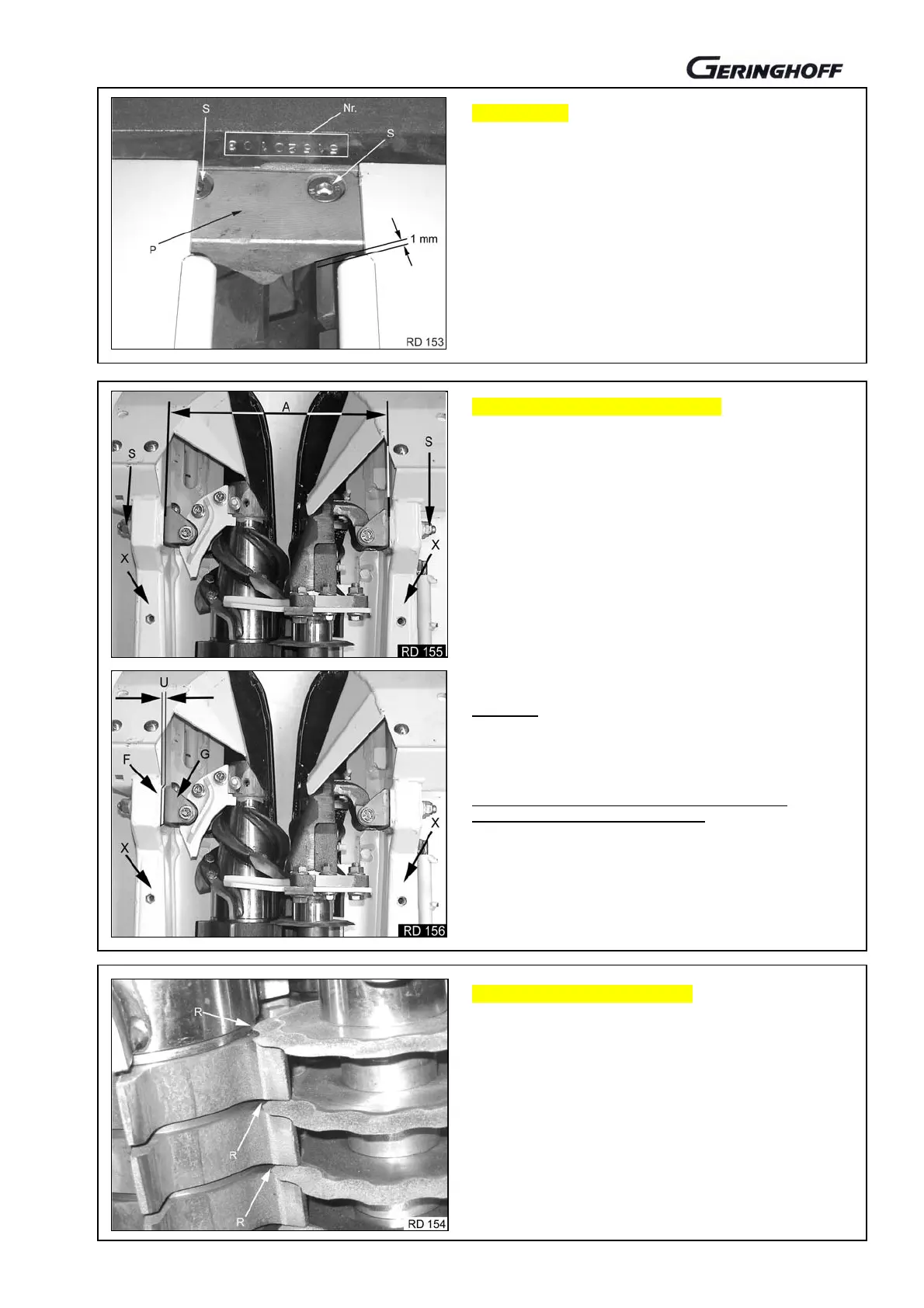

View of knife disks and rotors

It is a sure sign damage to the carrying arms of the row

units if the new knife disks do not engage deeply enough

into the grooves (R) of the rotors.

part from that, the stubble cutter does not allow for further

adjustment to the counter-knives (see page 10 / 000).

The row unit absolutely must be checked.

visual control of the row unit position for isolating any

problems is insufficient.

Loading...

Loading...