Gathering chains

09 / 520

Gathering chains

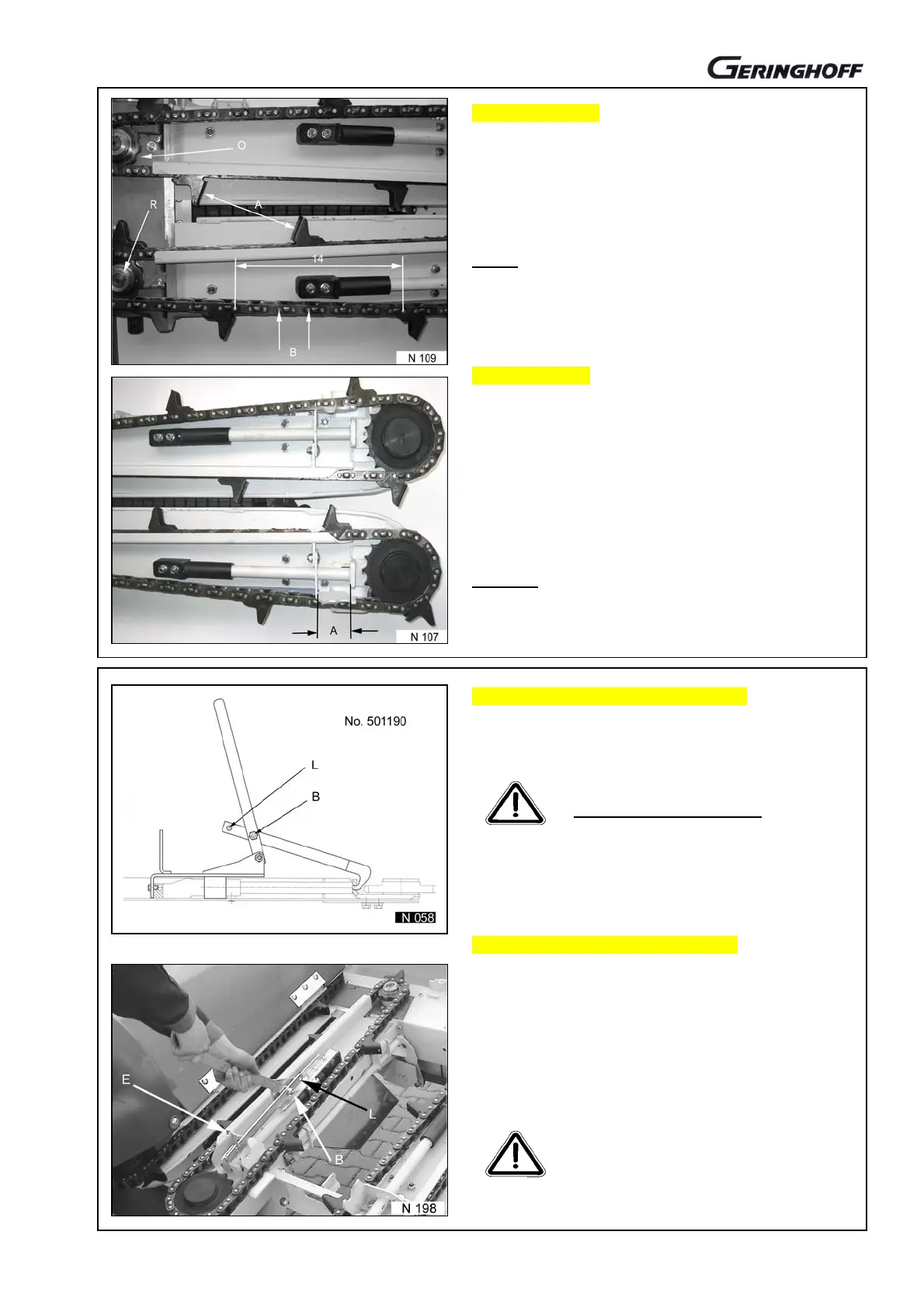

Special slipping wheels (R) are to secure the gathering

chains and to prevent the penetration of foreign substances.

The position of the gathering chain drivers (A) to each other

is permanently changing, even on normal harvest operation

by response of the slipping function.

When stating a chain elongation (ill. N 107), there is the

unique chance of shortening the chain by one outer and inne

link plate each (B). The shortening to be made in the area

(14) = 14 pces. link pin distance from driver to driver.

The plastic protective rings (O) beneath the slipping wheels

to be checked for good state.

Chain tensioner

The maintenance-free gathering chains are automatically

tensioned via constant spring pressure.

The preset chain tension is also to regulate the driving torque

of the gathering chain and thus the efficiency of the slipping

wheels.

When to change the gathering chains?

= 83 mm chain in new state

= 113 mm chain worn-out, replacement required.

Attention!

Consider also the wear of the frontal reversing wheels!

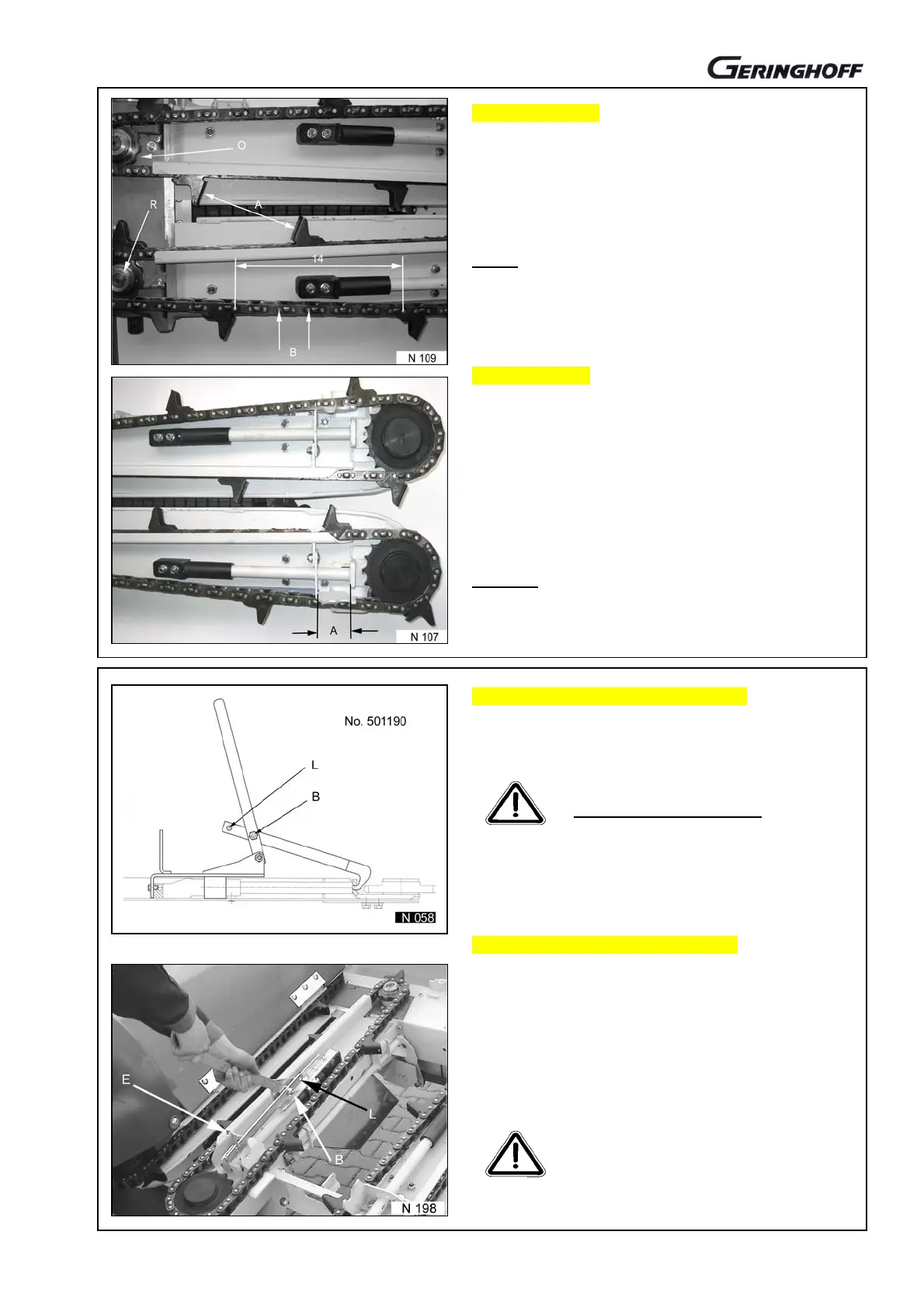

Dismounting of the gathering chains

The chains can be dismounted with ease by using a special

tool, spare part no.

501190 attached to the header.

Prior to working on the machine,

Diesel engine to turn off.

Special tool may jump back!

The gathering chains are recommended to be

changed once the year from right to left and

viceversa to ensure thus a uniform wear.

Frontal chain reversion to dismount

Tool for chain dismounting to place to pos. (B) as shown in

ill. N 058 and N 198 and to pull tight. Lever to secure under

hook (E).

The frontal reversing chain wheels to be dismounted in the

same way. Special tool to mount into bore (L). Lever to

secure under hook (E), then the fastening beneath the

reversing wheel to remove and tool slowly and carefully to

relieve.

Tool jumps back by !

spring pressure

Risk of accident!

Loading...

Loading...