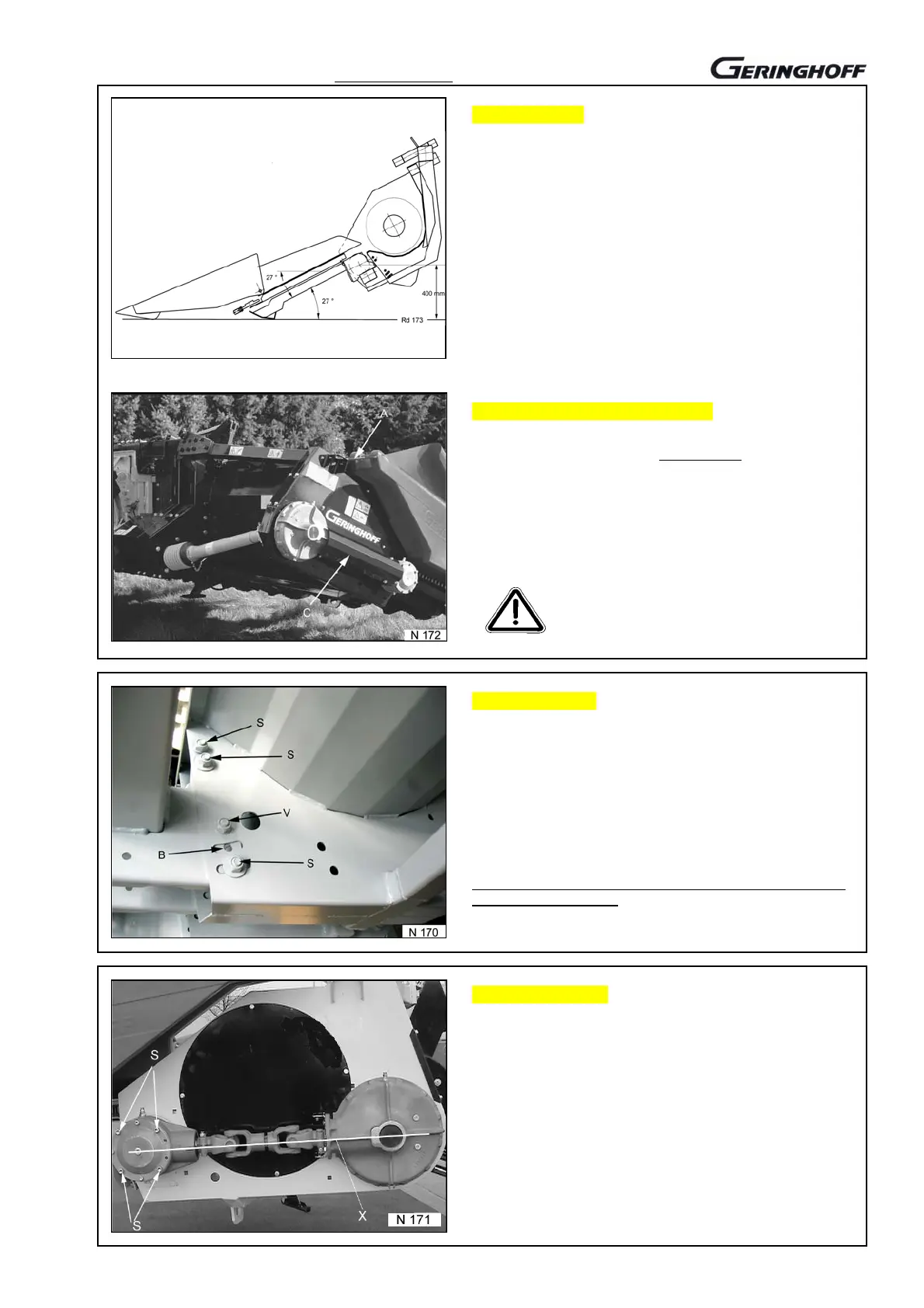

Rota –Disc* Working angle adjustment

Working angle (basic position)

working angle of 27° is factor

-set. If the combine is fitted

with larger or smaller tires than the series equipment, we

recommend checking the working angle. The same applies

also to crawlers.

The real angle is to be determined with ease by placing an

adjustable angle on the stripping plates in working position

and a bubble level.

This check should be made on real working conditions on

the field with the usual ground spacing.

When putting the header down to 27°, a control dimension

of about 400 mm of shaft spacing to the ground will result.

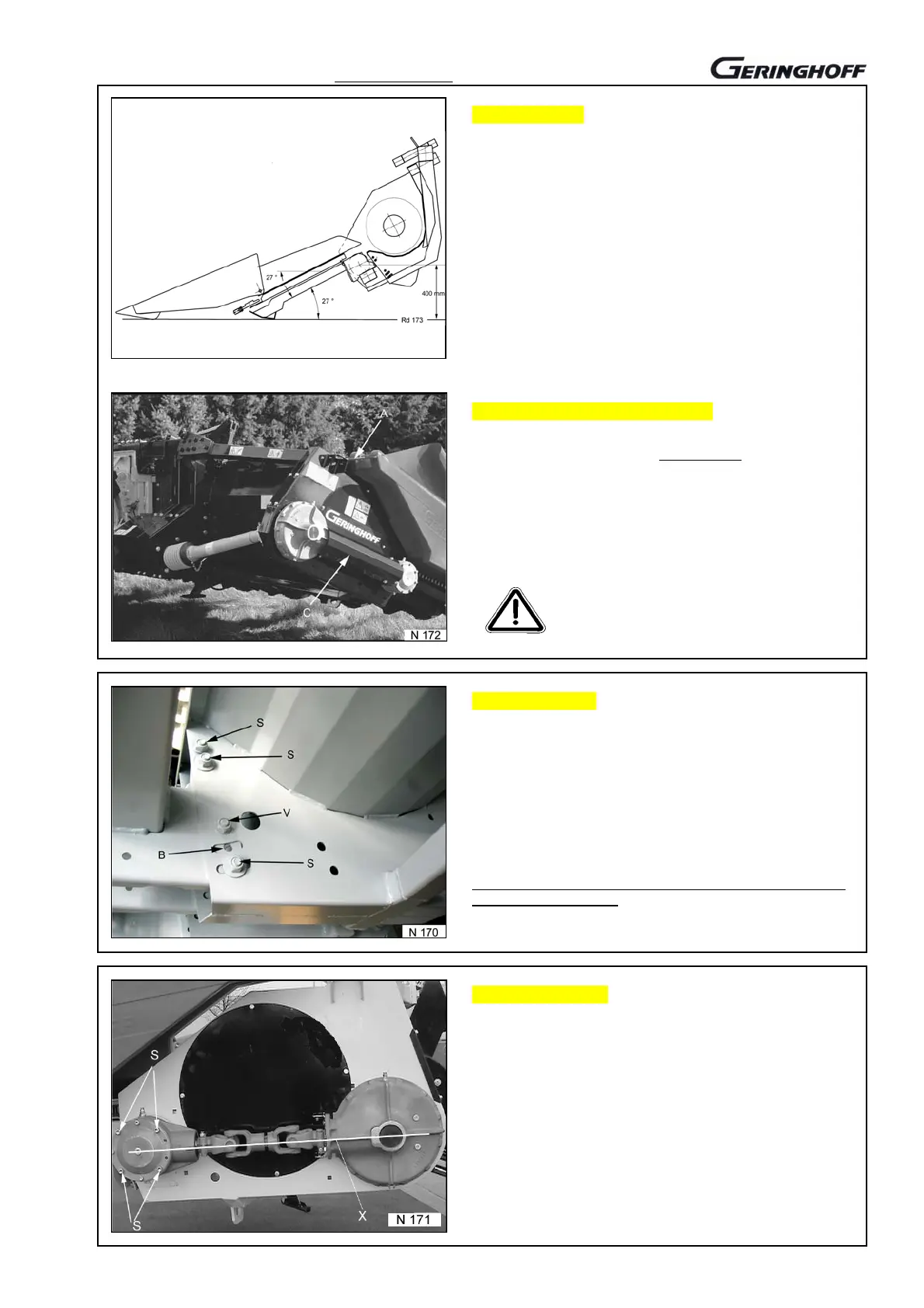

Adjustment of the working angle

Combine and corn header, completely mounted, to put

down in working position on a level surface.

Screwing of the outer bodywork suspension on the frame to

remove.

Guard (C) of the gear drive to remove.

On foldable headers, the locking must absolutely be

activated in working position (see 09/240).

Header, completely relieved but firmly

connected to the combine, to be put

down to the

round!

Adjusting device

When the machine has been put down, first the screw (V) to

remove from all frame connections and to put into the bore

(B).

Then, screws (S) on all frame connections, also on the

sidewalls, slightly to loosen for allowing the elements to be

moved to each other.

The required working angle to adjust via the lifting device of

the combine (header to lift and/or lower).

Then all screws of the frame connection to retighten with the

header being put down!

Drive gear to align

Corn header with the gathering channel to lift and secure

against unwanted lowering.

Only the four screws (S) Sw 8 of the angular gear and the

four screws of the contrate gear fastening on the backside

to loosen. Both the gears to turn until reaching the exact

alignment (see line X).

Gear to refasten and guard to remount.

Outer framework to be connected again. If required,

spacing to be compensated by spacers.

09 / 840

Loading...

Loading...