94

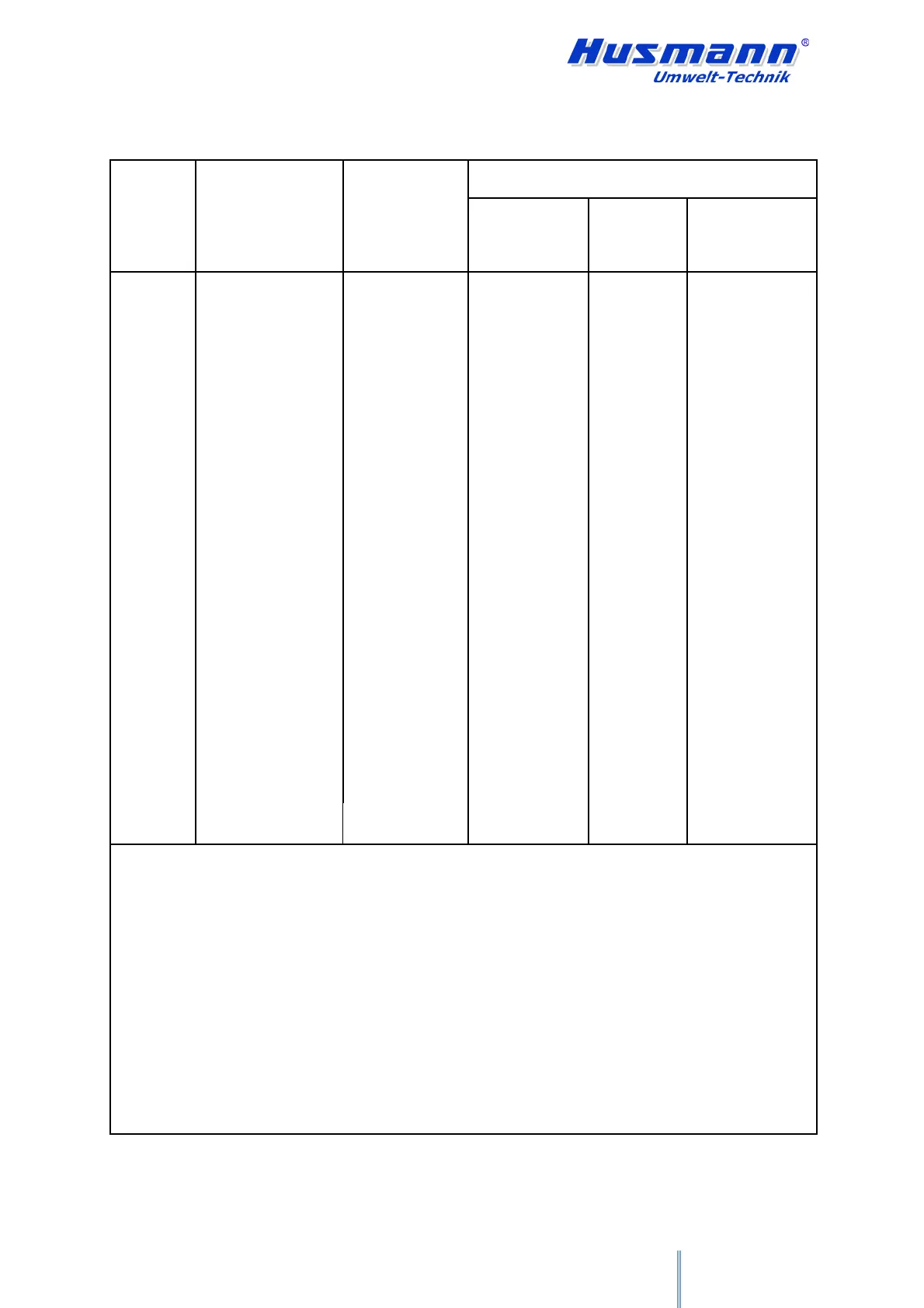

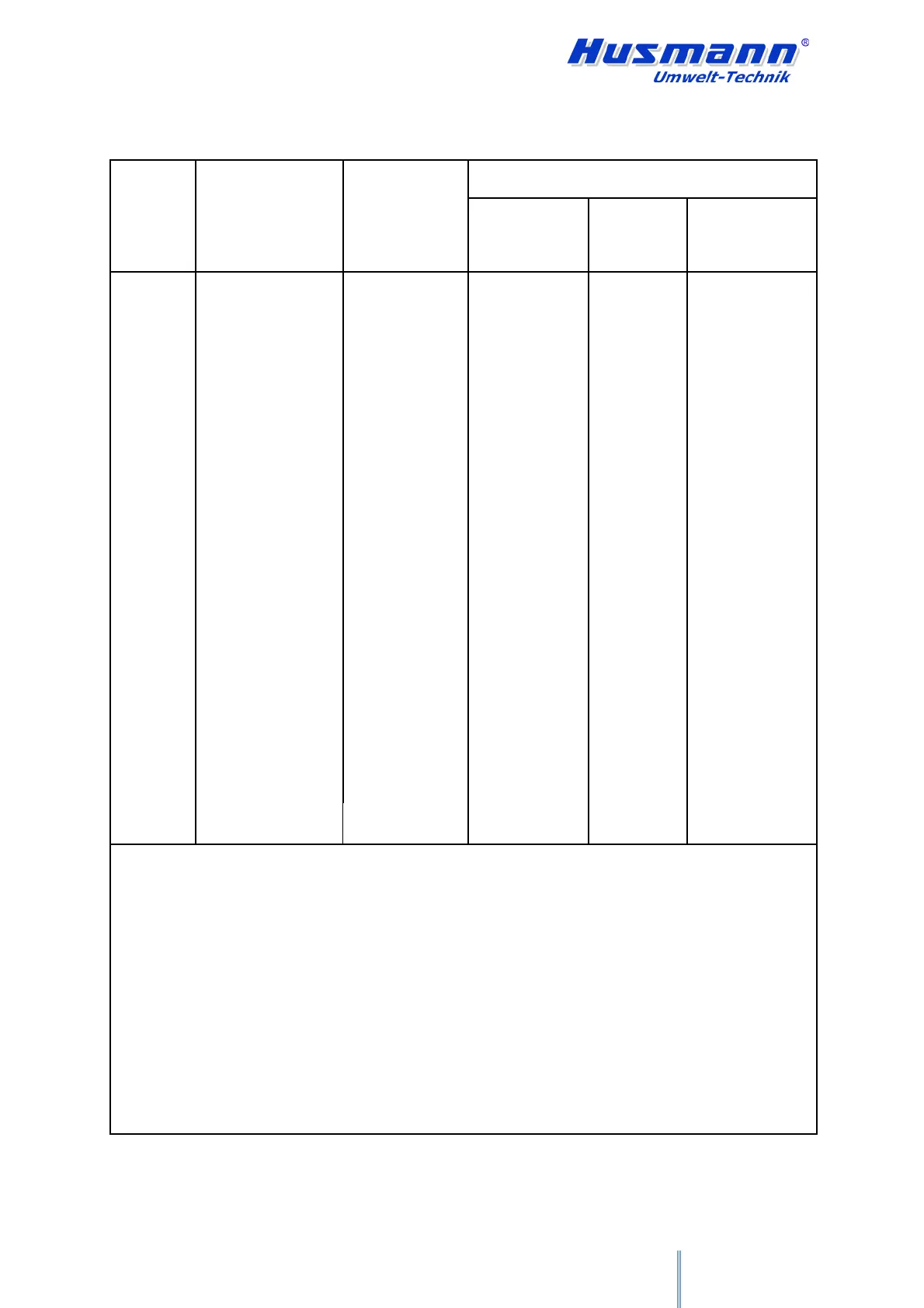

Lubrication instructions for portable compactor with pendulum ram

Time schedule

Pos. designation Part / condition

activity interval * remarks

01 door hinges - bearing KS # = ca. 500 grease nipple

02 container rollers

(rear)

- bearing S # = ca. 500 grease nipple

03 container ratchet - spindle KS # = ca. 500 apply with a brush

04 hydraulic power unit - oil level K *

(portable compactor) - tightness K *

- oil change

approx. 45 l 5,5

kW

approx. 100 l

7,5 kW

W # = ca. 2000

05 bearing shaft - bearing S # = ca. 500 grease nipple

06 compaction cylinder - bearing KS # = ca. 500 grease nipple

07

08

container rollers

cover above power

pack

- bearing

- door hinges

S

KS

# = ca. 500

# = ca. 500

grease nipple

grease nipple

* As needed, at the latest after interval. The inter-

vals refer to 8 working hours per day.

*

= daily

W=

change

&

= weekly

S = lubrication

$

= monthly

K = checking

§

= annually

R = cleaning

#

= about every .....

working hours

Loading...

Loading...