3.2 Screw fasteners

Metric threads are used on the product.

Some bolt fasteners are locked with screws treated

with Eslok

®

Nylon 180°. The screw threads have a

red coating. These screws can be retted 3 times

before they have to be replaced.

Always torque tighten screw unions as given in the

table, unless specied otherwise in the instruction.

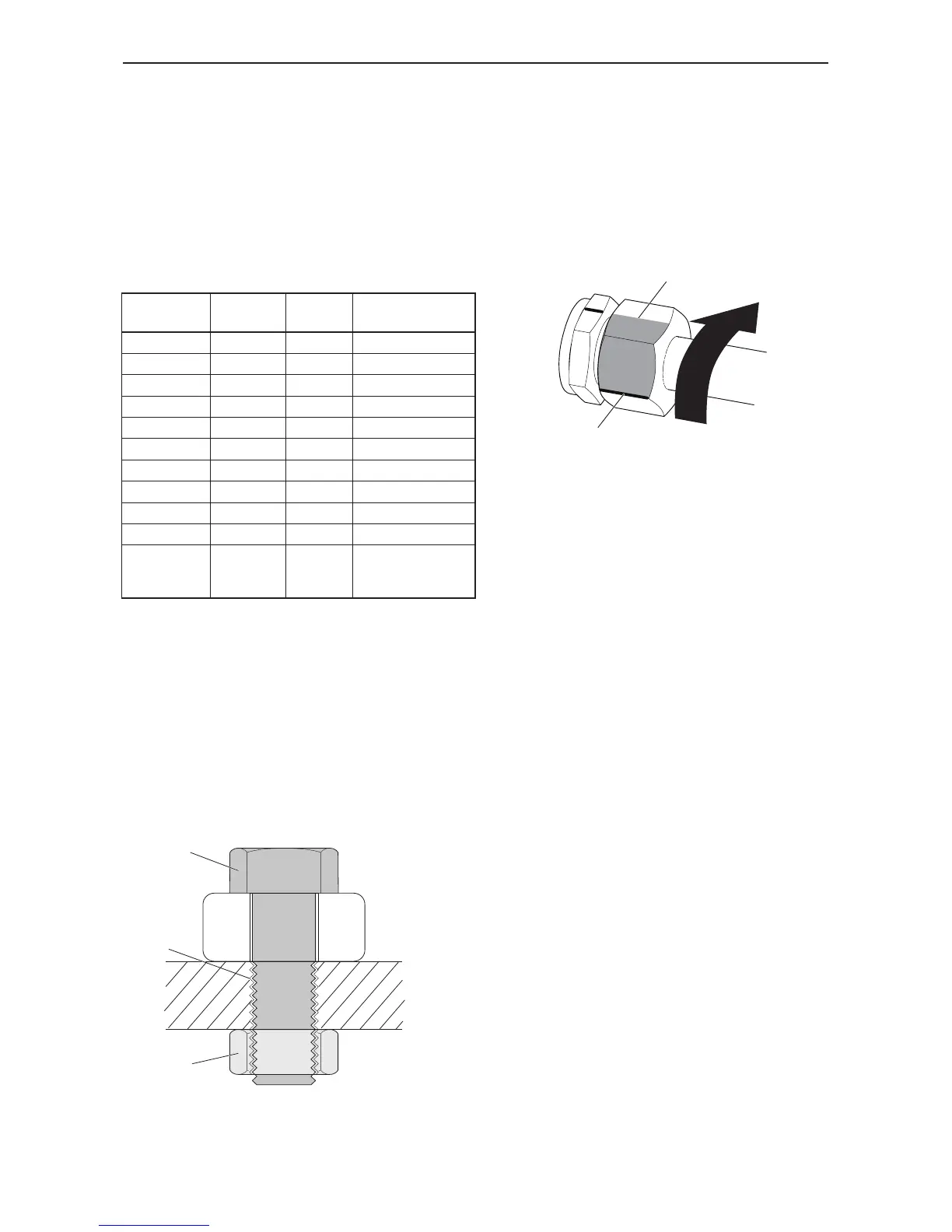

Spanner

size

Allen key Thread Tightening

torques

8 mm 4 mm M5 52 ft/lb (6 Nm)

10 mm 5 mm M6 52 ft/lb (10 Nm)

- - 3 mm M6 52 ft/lb (10 Nm)

13 mm 6 mm M8 52 ft/lb (24 Nm)

- - 4 mm M8 18 - 20 Nm

17 mm 8 mm M10 52 ft/lb (47 Nm)

17 mm - - M10 12.9 52 ft/lb (70 Nm)

18-19 mm 10 mm M12 52 ft/lb (81 Nm)

24 mm - - M16 80 ft/lb (110 Nm)

30 mm - - M20 52 ft/lb (200 Nm)

32 mm - - - - Hydraulic

couplings, see

separate chapter.

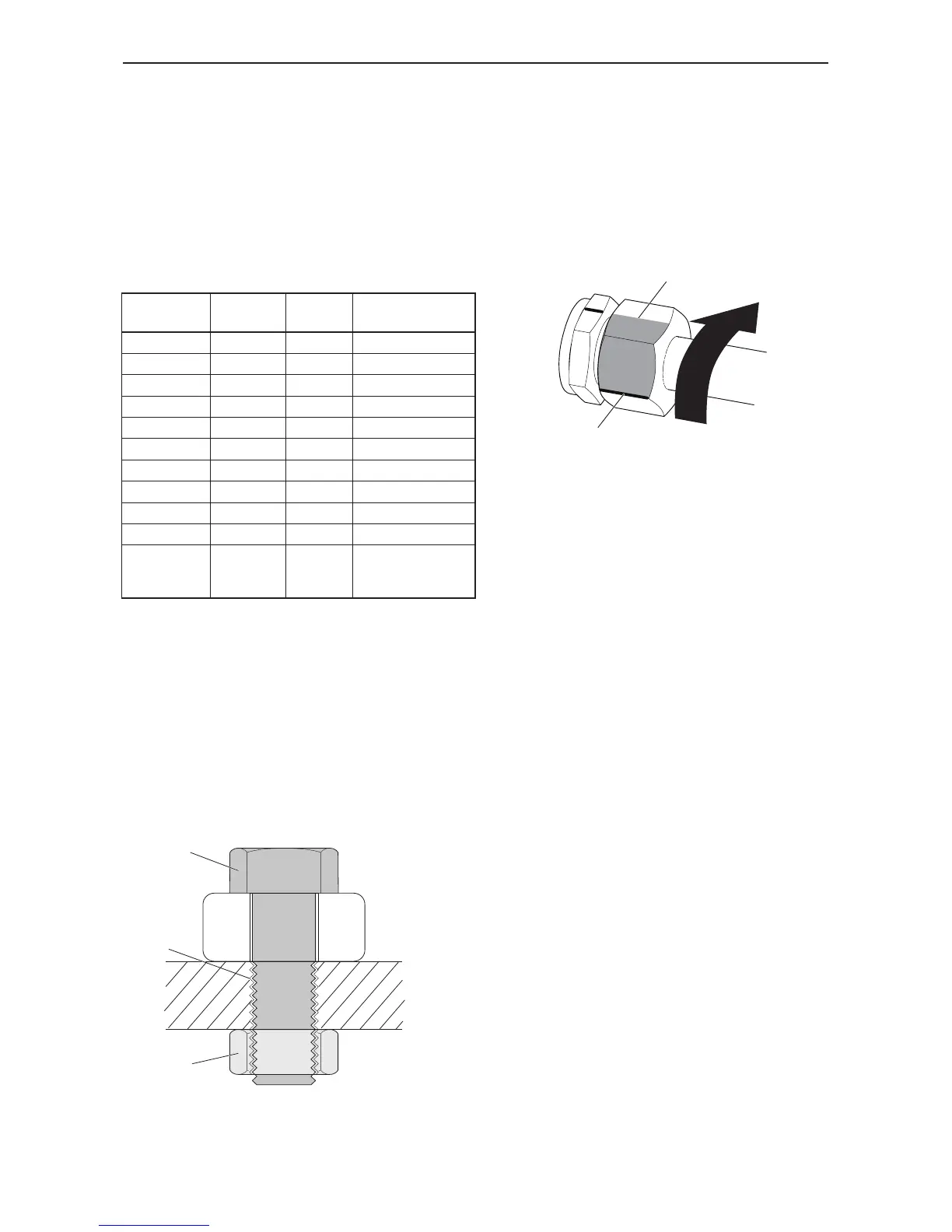

Certain unions are screwed into the goods with a

through screw and a locknut. The thread in the goods

is intended to take the eective torque and the

locknut is to secure the union during use.

Therefore, the main part of the torque - screw in the

goods - should always be tightened rst and then

secured with the locknut, which is tightened with less

torque. If the locknut is tightened with too high a

torque, the screw in the goods thread will be

unstressed and the bolt fastening will come loose

during use.

3.3 Hydraulic couplings

When hydraulic hoses and pipes that are NOT

specied on the next page, are assembled, rst

tighten their cap nuts by hand to a stop. Then tighten

a further 1½ ats of the wrench grip. This

corresponds to an approximate 90° turn.

Loading...

Loading...