English – 31

Propulsion

5.2.9 Hydrostatic cable

Tools Dimension

Combination wrench 10 mm

Flat-blade screwdriver

Hydrostatic cable adjustment

The hydrostatic cable may require adjustment.

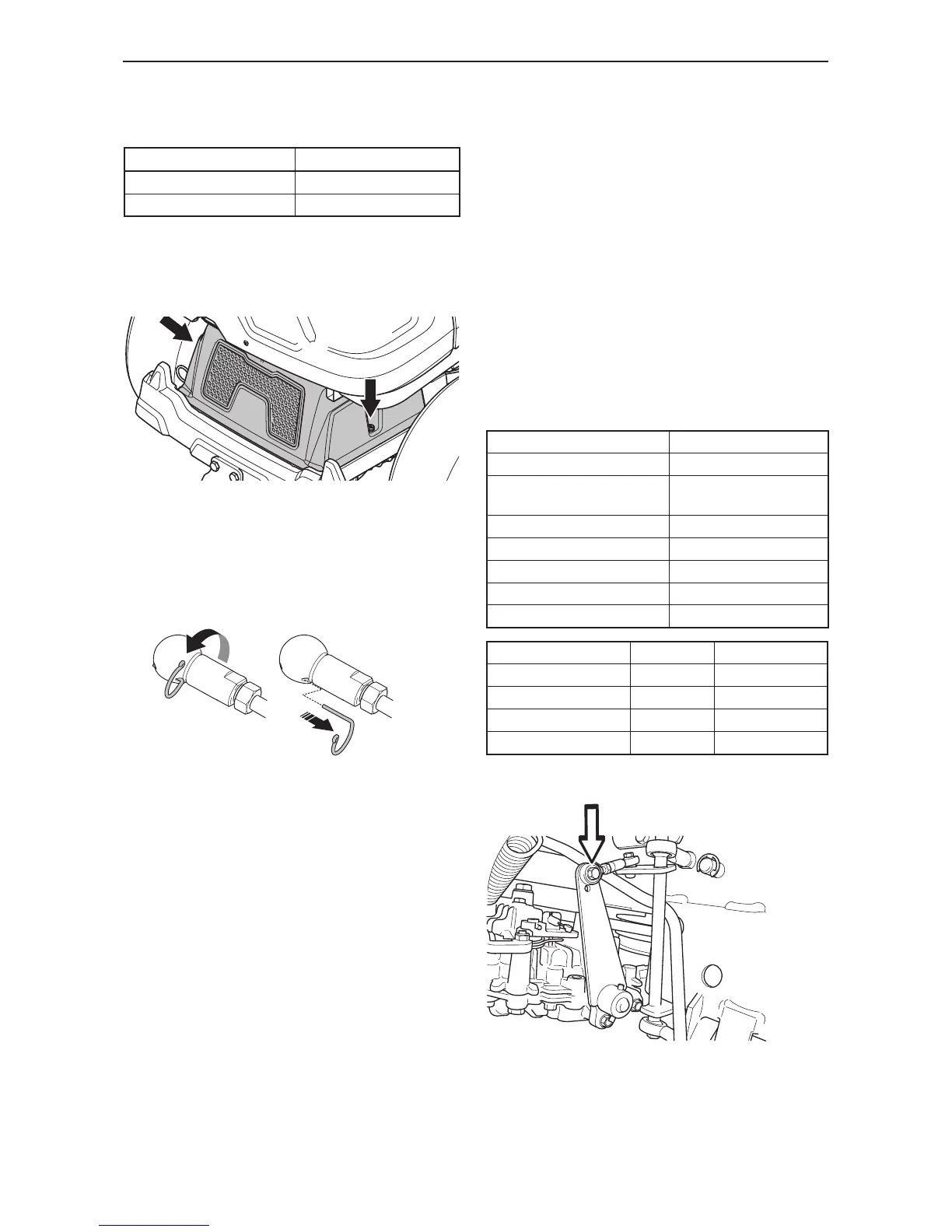

1. Remove the 2 screws that hold the transmission

cover, and lift o the cover.

2. Make sure that the front ball joint on the rod is

tted into the second hole from the top on the rear

control lever.

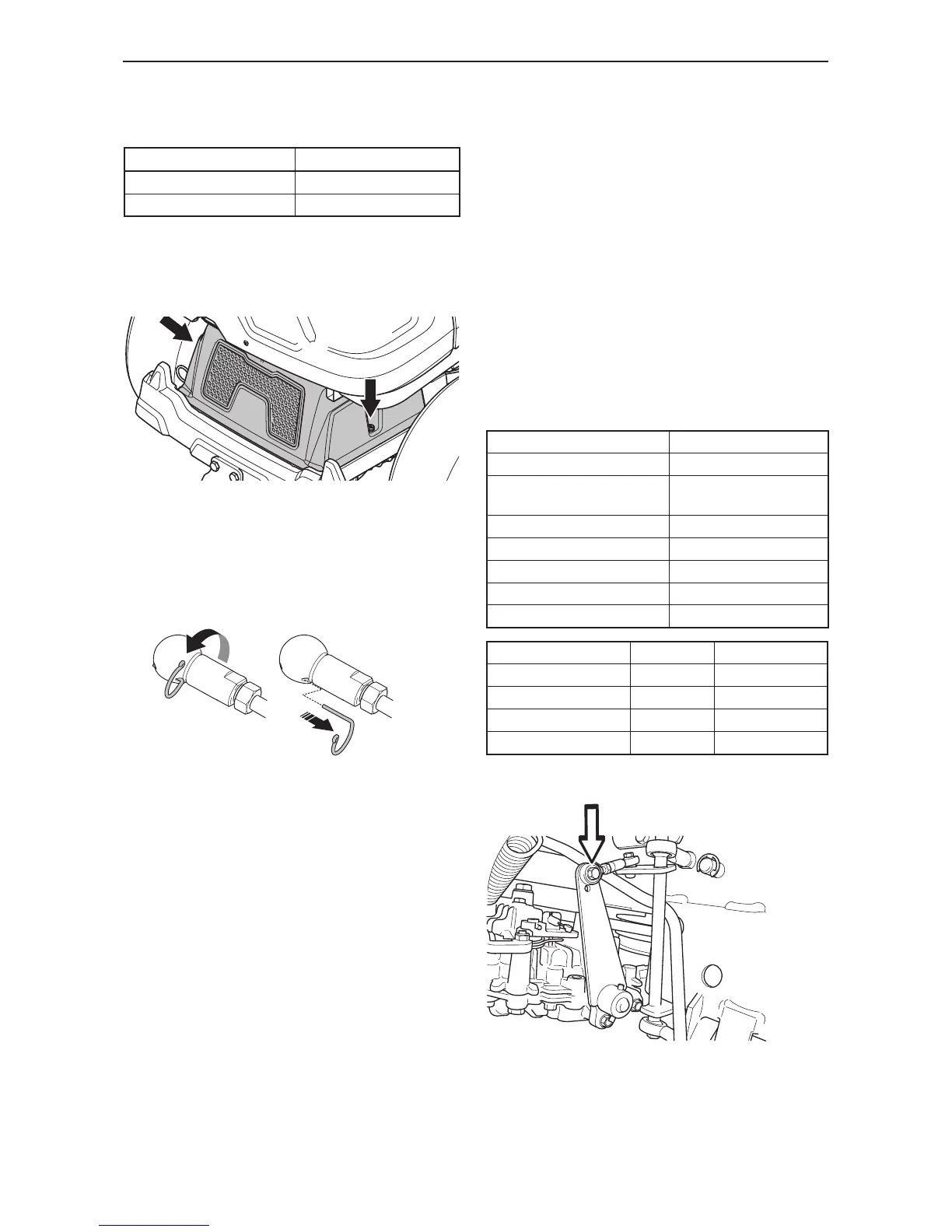

3. Separate the ball joint for the hydrostat cable, it is

secured with a lock spring.

1

2

4. Make sure that the forward drive pedal is

depressed fully.

5. Bend the arm to max position and check that the

ball and ball socket in the ball joint agree.

6. Adjust the ball socket on the cable as required so

that it ts precisely over the ball on the lever arm.

7. Screw in the ball socket a further 2 turns.

8. Assemble the ball joint.

9. Fit the ball joint lock spring.

10. Tighten the locknut for the ball socket on the

cable.

11. Attach the transmission cover.

NOTE: Make sure that the locking spring goes

through both holes in the ball socket.

5.2.10 Wheel speed

Front and rear wheel drives must be adjusted so that

the speed between the front and rear wheels is

correct when cornering. In order to prevent

measurement error due to rollback on the dierntial

wheels, 2 of the wheels of the product must make

contact with the ground.

Make sure that the steering wheel postion does not

change while work is in progess.

Measure with the Husqvarna optical revolution

counter. Front wheel speed should be 0.95-1.0 of the

rear wheel speed. Note that the variation between the

wheel speeds is dierent on delivery. See table

below.

Synchronising front and rear wheel drives

Tools Dimension

Torx T30

Tool for measuring wheel

speed

--

Laser meter --

Reective tape --

Combination wrench 14 mm x2

Combination wrench 15 mm

Combination wrench 17 mm x2

Time Action Value

Production -- 0.92-0.95

8h Check 0.95-1.0

25h Check 0.95-1.0

Every 25h Check 0.95-1.0

1. Check that the lower synchronisation is tted in

the upper hole as shown in the illustration.

Loading...

Loading...