TroubleshooTing and sysTem TesTs

powermax

65/85

Service Manual 5-35

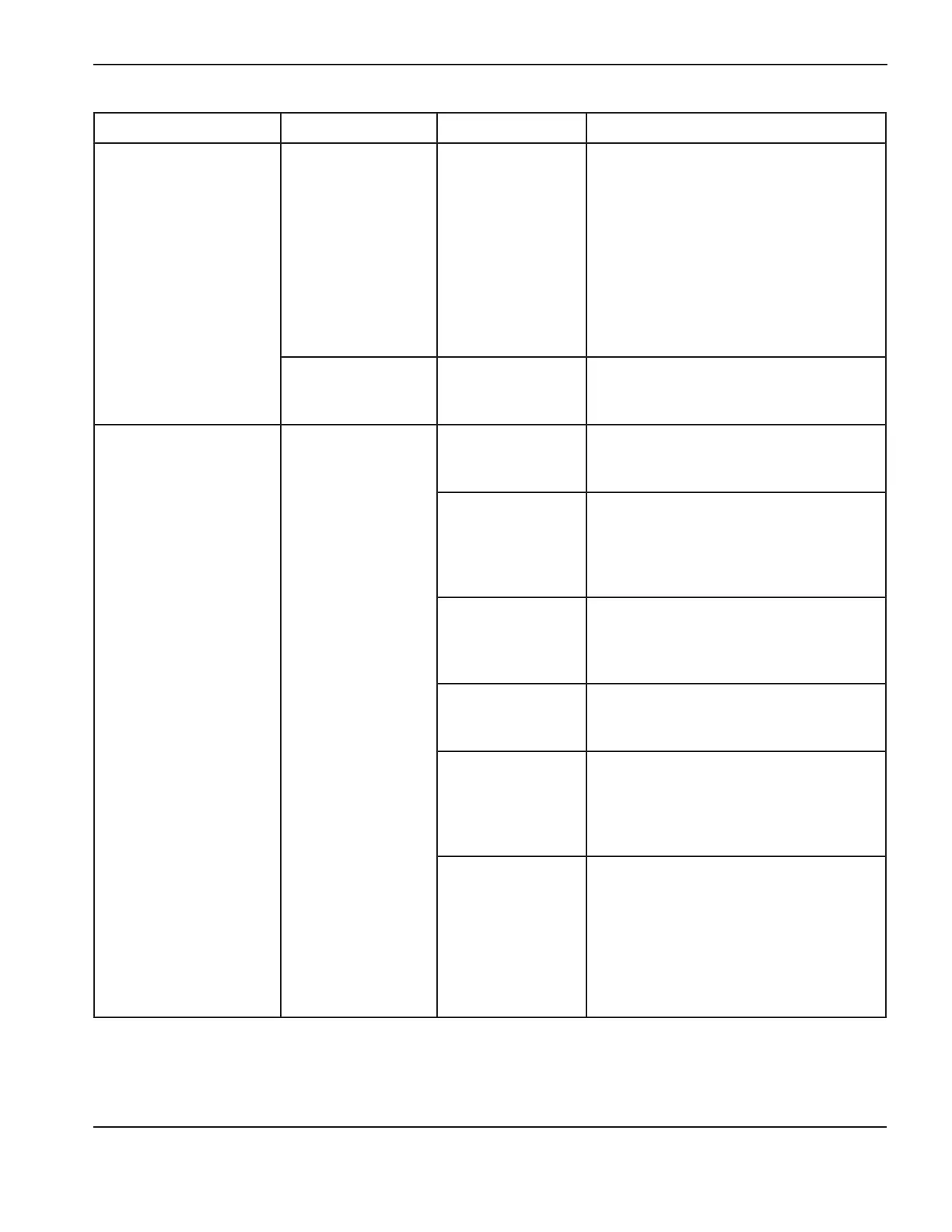

Problem Meaning Causes Solution

Arc goes out while

cuttingor intermittently

willnot fire.

The arc lost contact

with the workpiece.

• The work lead

or work lead

connection may

be faulty.

• The material

being cut may

require the use of

continuous pilot

arc mode.

• If you are cutting expanded metal, grate,

or any metal with holes, set the mode

switch to continuous pilot arc mode.

• Check for loose connections at the work

clamp and at the power supply.

• Reposition the work lead on the

workpiece.

• Clean the cutting surface to ensure a

better connection with the work lead.

Faulty fan.

• The fan could be

overloading the

flyback circuit.

• Perform Tests 5 and 11.

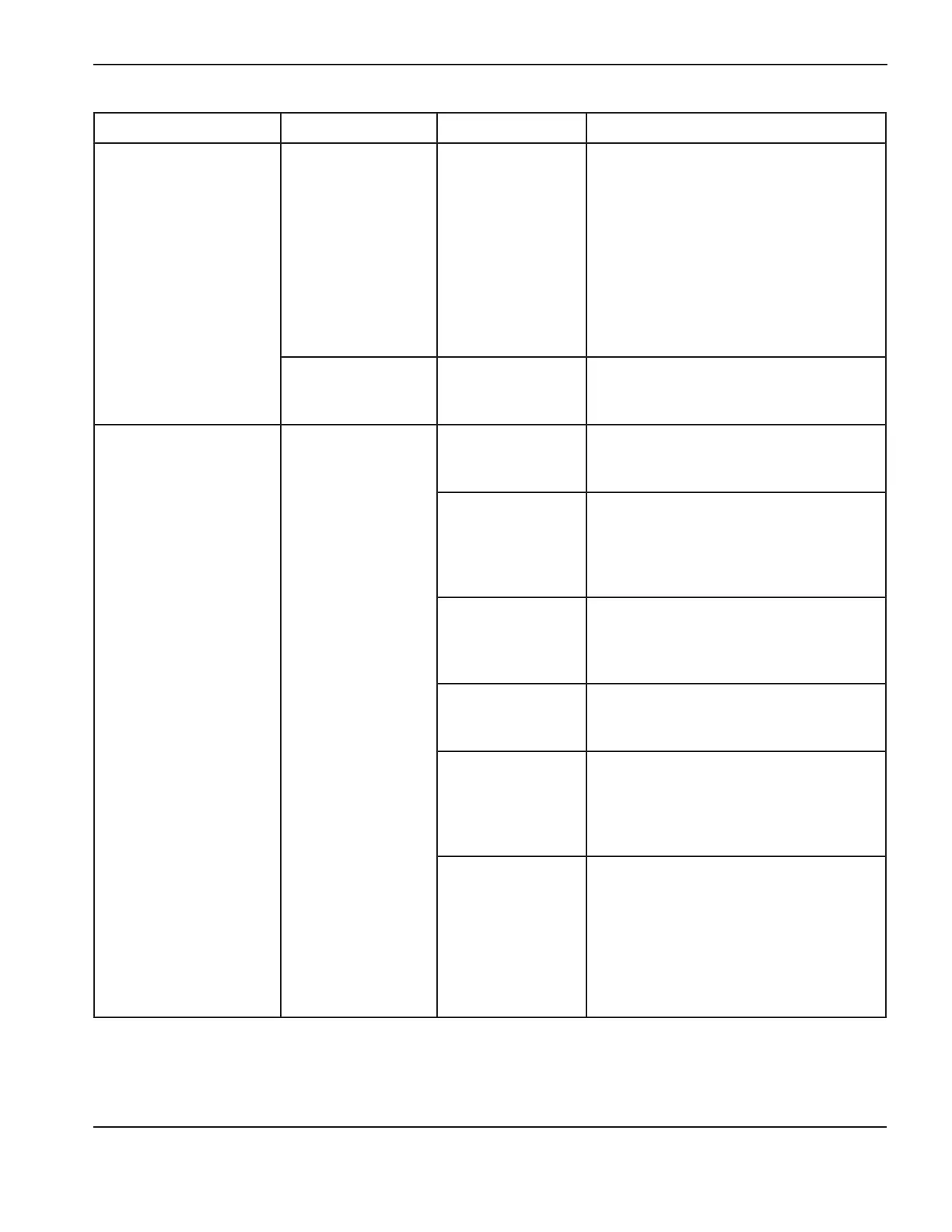

The cut quality is poor

orthe cut does not sever

the metal.

The consumables

are worn, there is

a poor work lead

connection, the

output from the

power supply is

too low, the power

board is producing

low current, or the

selected cutting

mode is incorrect..

• The consumables

need to be

replaced

• Inspect the consumables and replace if

necessary.

• The work lead

may be damaged

or not properly

connected to the

work piece

• Inspect the work lead for damage.

Reposition it and clean the work surface

to ensure good contact.

• The amperage

adjustment knob

may be set too

low.

• Increase the amperage as needed.

• The power board

(PCB3) may be

faulty.

• Perform Tests 1, 2, and 3 and replace

any faulty components.

The cutting mode

switch is in the

wrong position

for the cutting

operation.

• Ensure the cutting mode switch is in the

correct position.

• Faulty pilot arc

IGBT.

• Turn the power OFF, remove the

consumables, and check the resistance

between the cathode and the work

clamp. If the resistance is less than

5kΩ, check the resistance across the

pilot arc IGBT (two screws on 08). If the

resistance is less than 5kΩ, replace the

pilot arc IGBT.

Loading...

Loading...