TroubleshooTing and sysTem TesTs

5-36 powermax

65/85

Service Manual

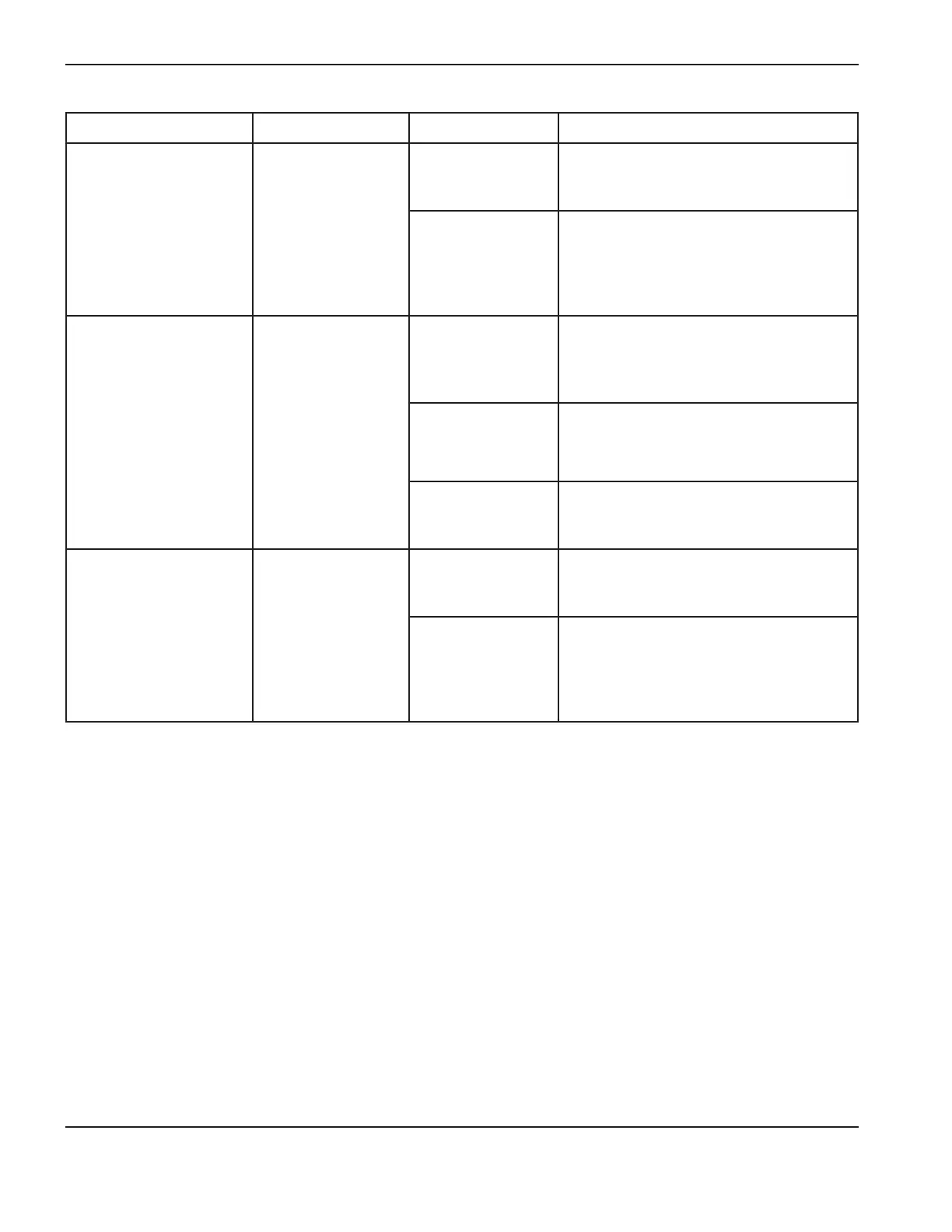

Problem Meaning Causes Solution

While in continuous pilot

arc mode, the pilot arc

extinguishes when you

move the plasma arc off

the work piece while still

pulling the torch’s trigger.

The continuous pilot

arc feature is not

working.

• The mode switch

may be set

incorrectly

• Verify that the mode switch is set to

continuous pilot arc.

• The power board

(PCB3) or the

control board

(PCB1) may be

faulty.

• Perform Tests 1, 2, and 3 and replace

the power board (PCB3) or control

board PCB1) if necessary.

The arc extinguishes, but

re-ignites when the torch

trigger is pressed again.

The consumables

are worn or

damaged, the gas

filter element is

contaminated, or the

input gas pressure

is not at the proper

level.

• The consumables

need to be

replaced.

• Replace the consumables as needed.

• The gas filter

element needs to

be replaced.

• Replace the gas filter’s element if it is

contaminated.

• The gas pressure

is too high or too

low.

• Manually adjust the gas pressure as

needed.

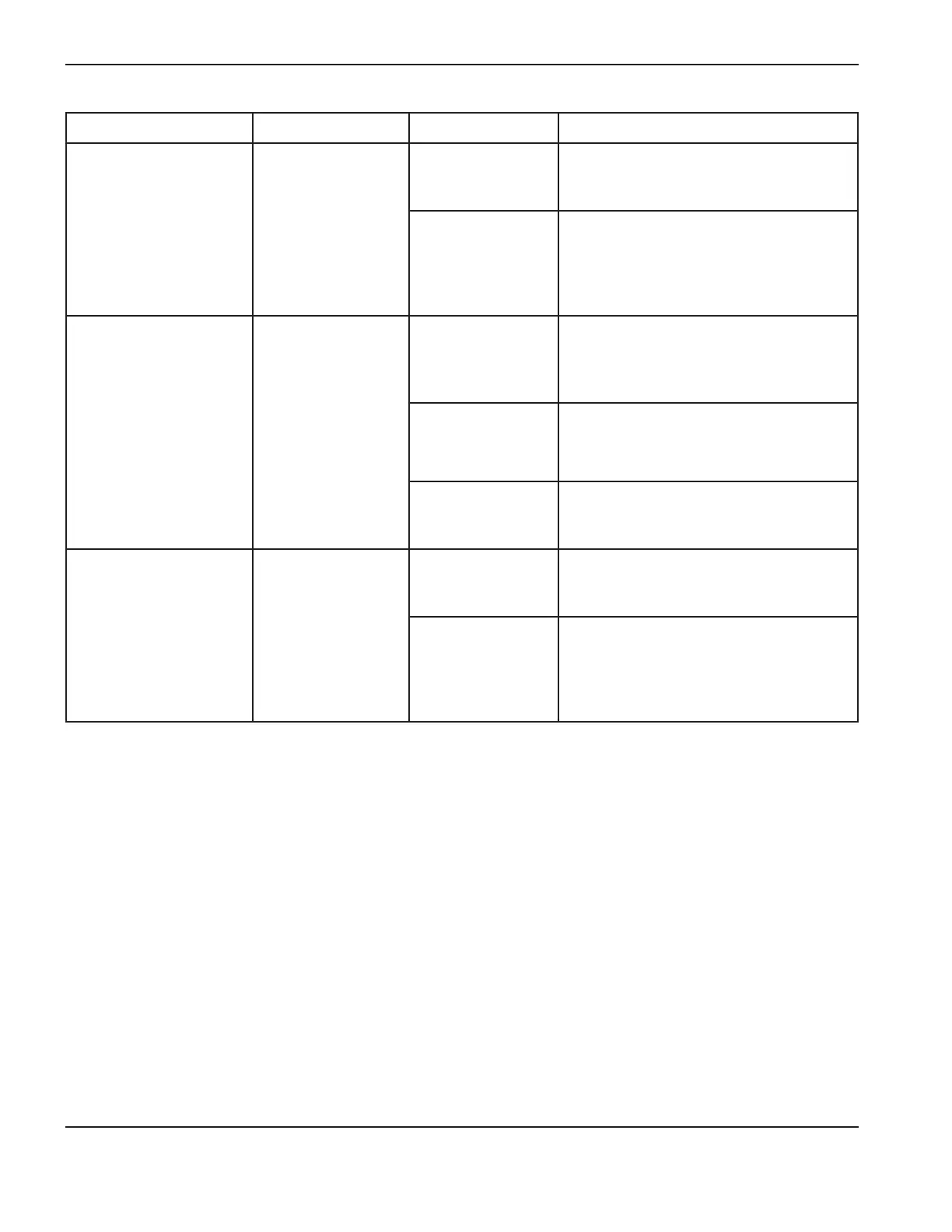

The arc sputters and

hisses.

The gas filter element

is contaminated, or

the input gas line

contains moisture.

• The gas filter

element needs to

be replaced.

• Replace the gas filter’s element if it is

contaminated.

• The input gas

supply needs to

be cleaned.

• Inspect the gas line for moisture. If

necessary, install or repair the gas

filtration to the power supply. See

Section 2, Power Supply Setup, for

more information.

Loading...

Loading...