140

8.2.4 Servo Gain Adjustment

Before the shipment, the servo has been adjusted in accordance with the standard specification of the

actuator. Accordingly, the servo settings need not be changed in normal conditions.

Nonetheless, the parameters relating to servo adjustment are made accessible by the customer so that

speedy actions can be taken in situations where vibration or noise occurs due to the affixing method of the

actuator, load condition, or the like.

In particular, custom types (having a longer ball screw lead or stroke than standard types) are more

vulnerable to vibration and noise due to external conditions.

In these circumstances, the following parameters must be changed. Contact IAI for details.

Servo gain number (No.7 PLG0)

Parameter No. Unit Input range Default

7 5 rad/sec 0 ~ 31 6

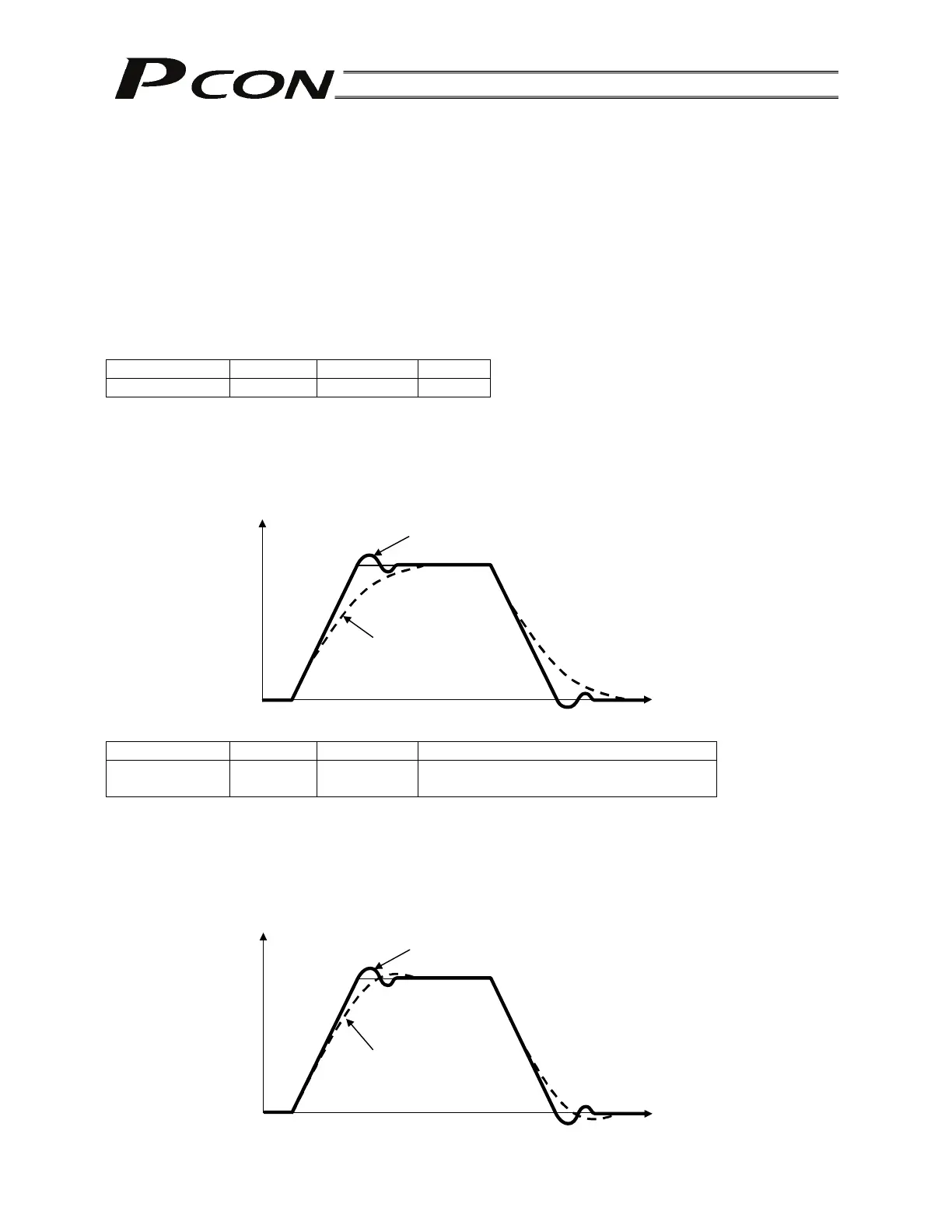

This parameter determines the response when a position control loop is used.

Increasing the set value improves the tracking performance with respect to the position command.

However, increasing the parameter value excessively increases the chances of overshooting.

If the set value is small, the tracking performance with respect to the position command drops and

positioning takes a longer time.

Speed loop proportional gain (No.31 VLPG)

Parameter No. Unit Input range Default

31 --- 1 ~ 27661

Set individually in accordance with the

actuator characteristics.

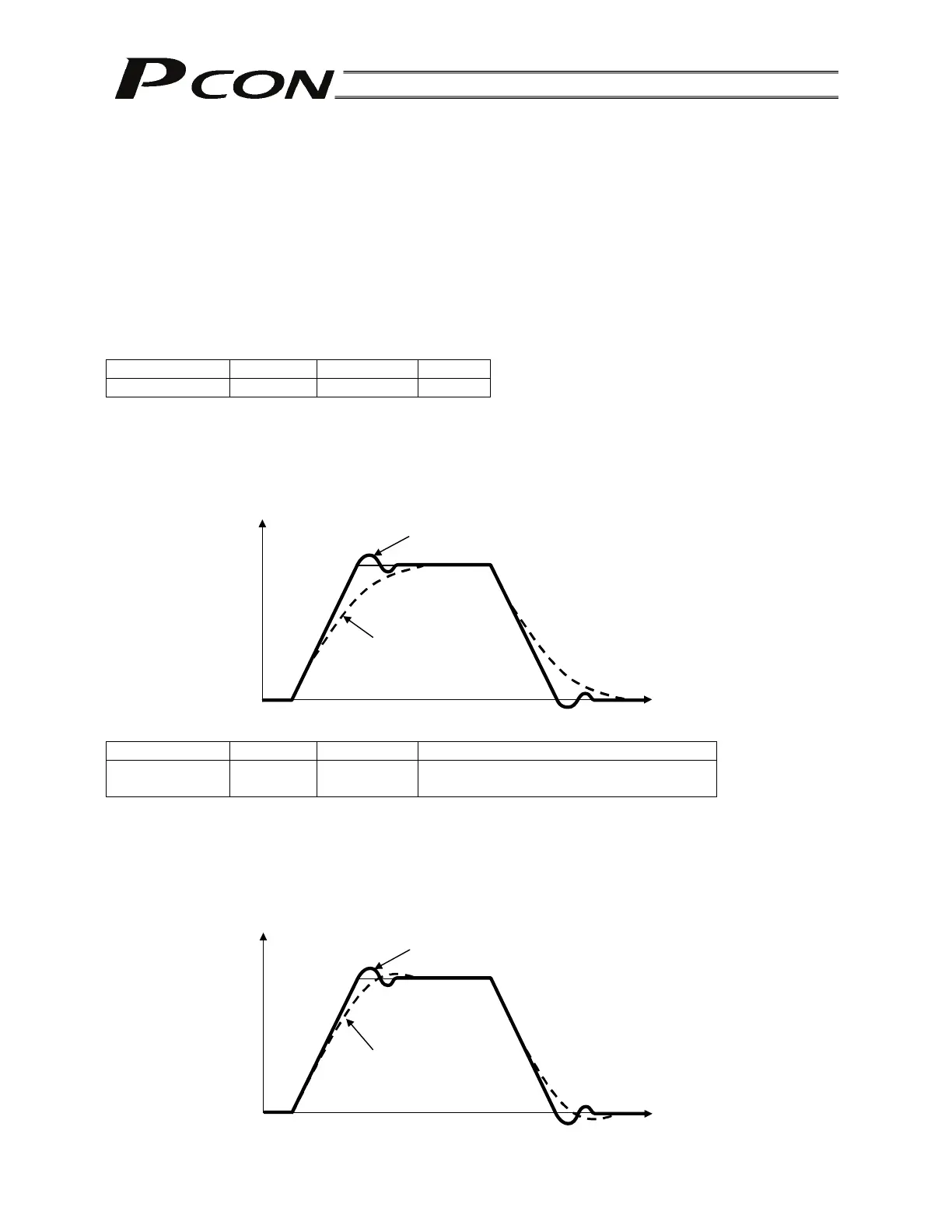

This parameter determines the response when a speed control loop is used.

Increasing the set value improves the tracking performance with respect to the speed command (i.e.,

servo rigidity increases).

The greater the load inertia, the larger this parameter value should be.

However, increasing the parameter value excessively makes the actuator more vulnerable to overshooting

or shaking, leading to mechanical vibration.

Speed

Set value is large (overshooting).

Set value is small.

Time

Speed

Set value is large (overshooting).

Set value is small.

Time

Loading...

Loading...