12

3. Installation and Noise Elimination

Pay due attention to the installation environment of the controller.

3.1 Installation Environment

(1) When installing and wiring the controller, do not block the cooling ventilation holes. (Insufficient

ventilation will not only prevent the controller from demonstrating its full performance, but it may also

cause breakdown.)

(2) Prevent foreign matter from entering the controller through the ventilation holes. Since the enclosure

of the controller is not dustproof or waterproof (oilproof), avoid using the controller in a place subject

to significant dust, oil mist or splashes of cutting fluid.

(3) Do not expose the controller to direct sunlight or radiating heat from a large heat source such as a

heat treatment furnace.

(4) Use the controller in an environment free from corrosive or inflammable gases, under a temperature

of 0 to 40C and humidity of 85% or less (non-condensing).

(5) Use the controller in an environment where it will not receive any external vibration or shock.

(6) Prevent electrical noise from entering the controller or its cables.

3.2 Power Supply

The power supply specification is 24 VDC 10%.

(Supply current: 2 A max.: C/CG, 6 A: CF)

3.3 Noise Elimination and Grounding

This section explains how to eliminate noise in the use of the controller.

(1) Wiring and power supply

[1] Provide a dedicated class D grounding using a wire with a size of 2.0 to 5.5 mm

2

or larger.

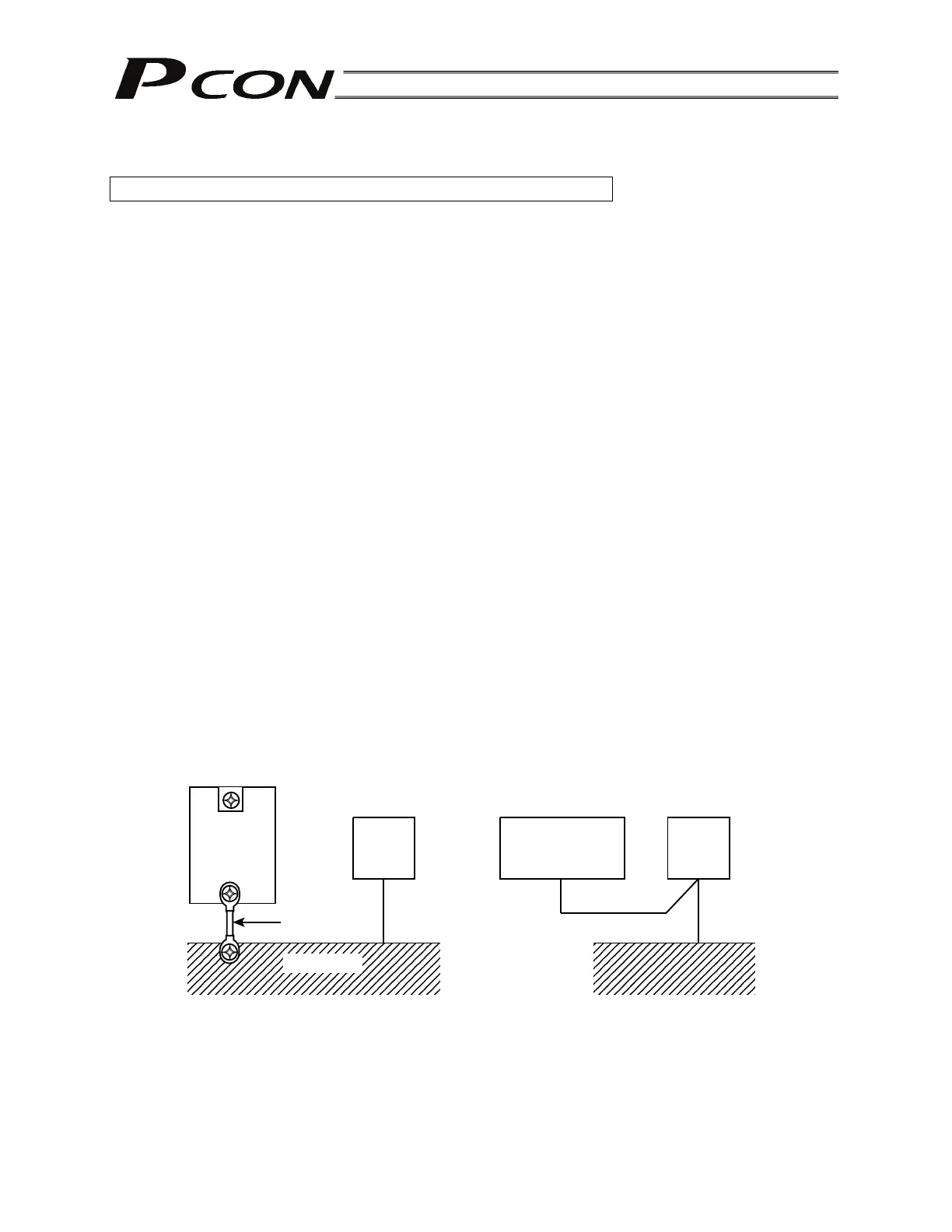

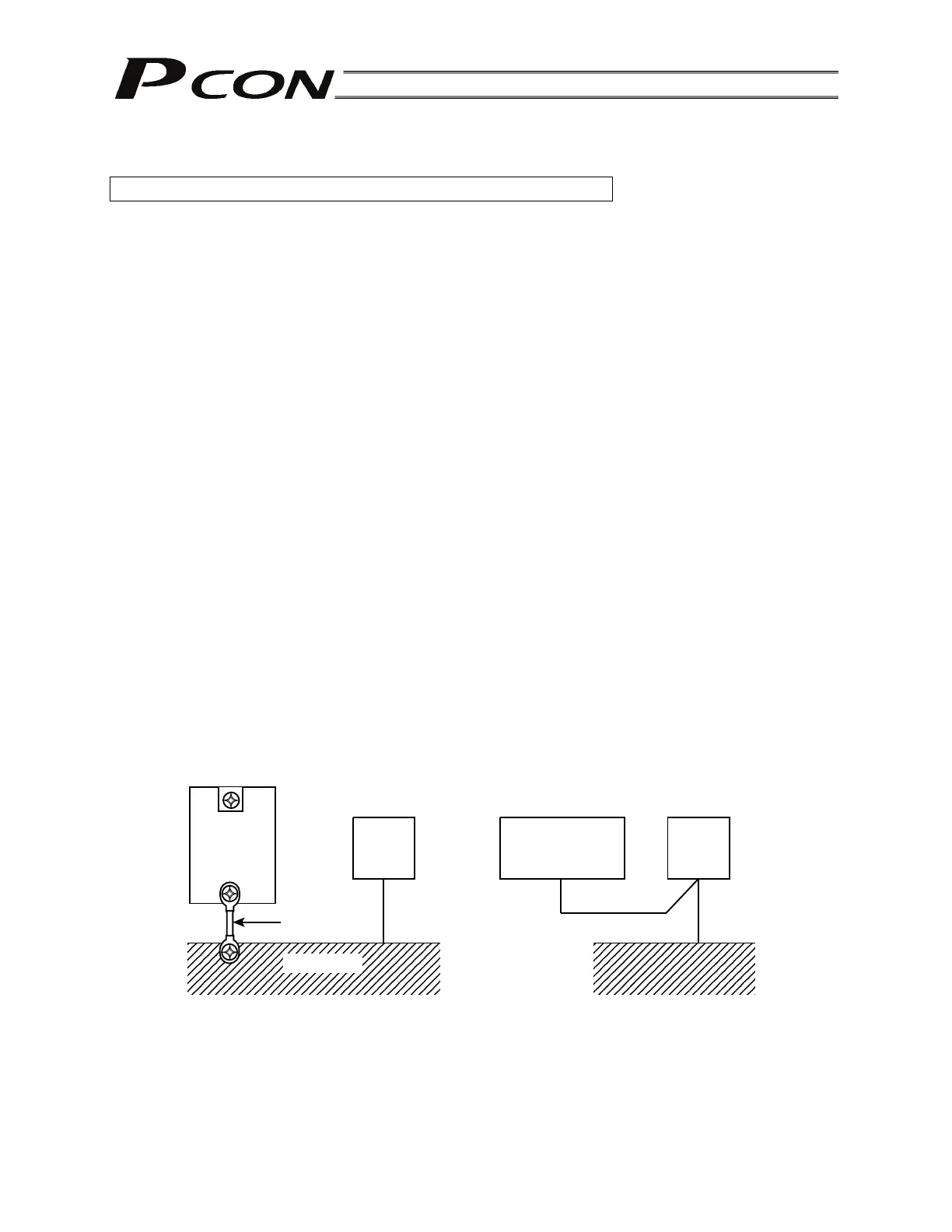

Class D grounding Good Avoid this grounding method.

Controller

Other

equipment

Controller

Other

equipment

Use a cable of a

maximum possible

size and keep the

wiring length at a

minimum.

Metal frame

Loading...

Loading...