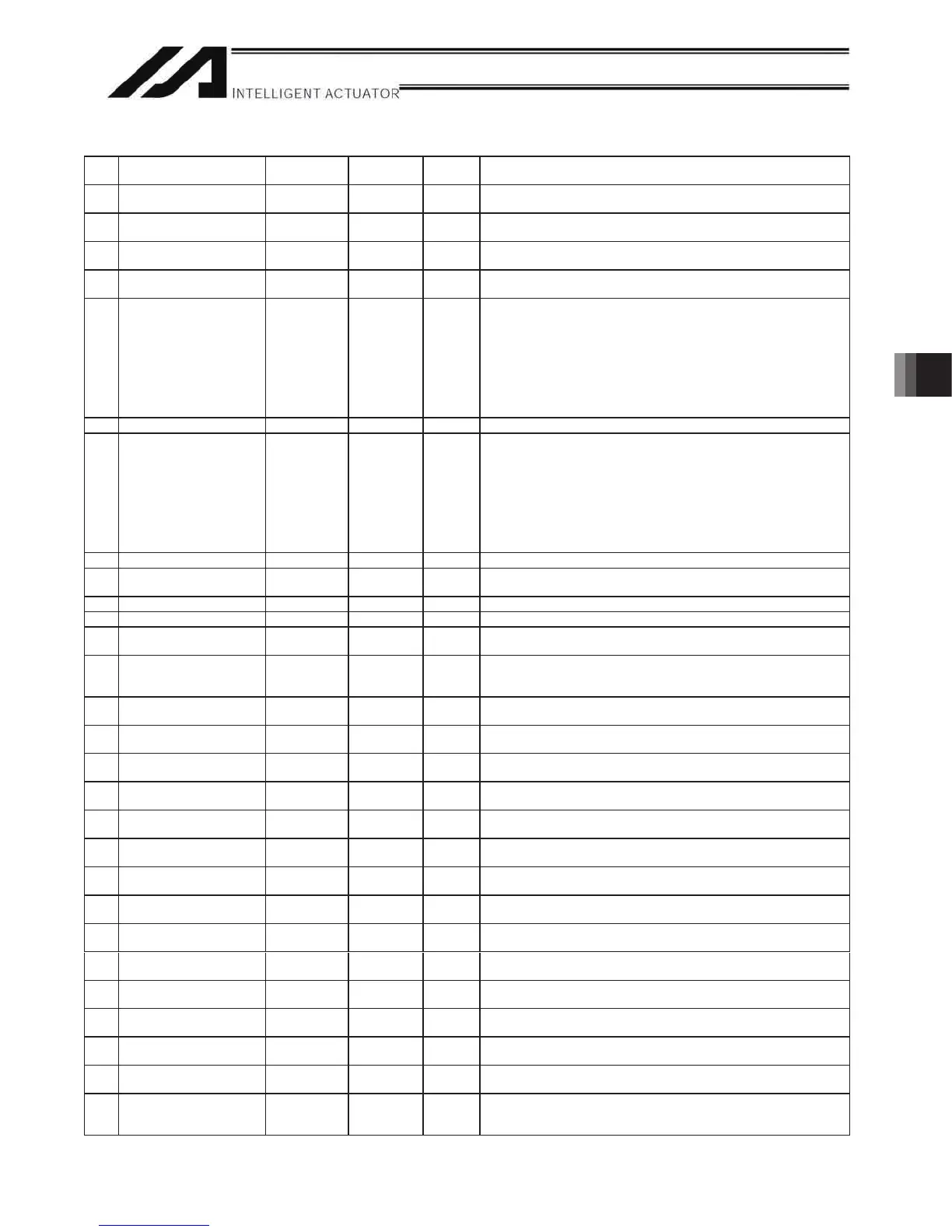

449

Appendix

Appendix

Axis-Specific Parameters

No. Parameter name

Default value

(Reference)

Input range Unit Remarks

72 '5995RIIVHW 0 Reference

only

DRVVR (Change prohibited) To maintain symmetry of the positive and negative

sides.

73 DRVVR – offset 0 Reference

only

DRVVR (Change prohibited) To maintain symmetry of the positive and negative

sides.

74 For future expansion 0 Reference

only

75 For future expansion 0 Reference

only

76 Home-adjustment parameter

set selection

1 Reference

only

(Change prohibited)

0: P21 = Phase-Z evacuation distance at INC home return

P12 = Ideal phase-Z position coordinate

1: P32 is read automatically even when P33 = 0. P33 = 0 indicates “actual

distance.”

P21 = Offset travel at home return

P12 = Coordinate achieved by offset travel at home return

P26 = Invalid

(To facilitate adjustment)

77 Synchro S pulse 3 0 to 99999 Pulse * Related information: Axis-specific parameter No. 52

78 Maximum takeoff command

amount

0 -3000 to 3000 0.001 mm Maximum lift command amount before brake unlock (Input with sign)

(Suppression of momentary drop upon servo ON when a heavy object is

placed)

* Important: Input using the same sign as the rising coordinate direction.

(0.100 mm to 0.500 mm in absolute value as a guideline)

* The servo-ON check time (axis-specific parameter No. 30) must also be

extended (approx. 1000 to 1500 msec) to provide a sufficient time for rise-

direction torque to follow.

(Valid only when installation of brake is specified.)

79 Actual takeoff check distance 5 0 to 3000 0.001 mm Absolute value input

80 Maximum forced-feed range 0 0 to 9999 0.001 mm For reduction of settling time. (Invalid range if “0” is set)

(Approx. 1.000 mm as a guideline)

81 Minimum forced-feed range 200 0 to 9999 0.001 mm

82 Medium forced-feed range 600 0 to 9999 0.001 mm

83 Absolute synchro slave-axis

initialization cancellation

0 0 to 5 Valid only with a synchro slave axis.

84 Maximum synchronization

correction speed of synchro

slave axis

5 0 to 100 mm/sec Maximum travel speed for synchronization position correction of slave axis.

Valid only with a synchro slave axis.

* Note: Not limited by the safety speed.

85 Home-return acceleration/

deceleration

15 1 to 300 0.01 G

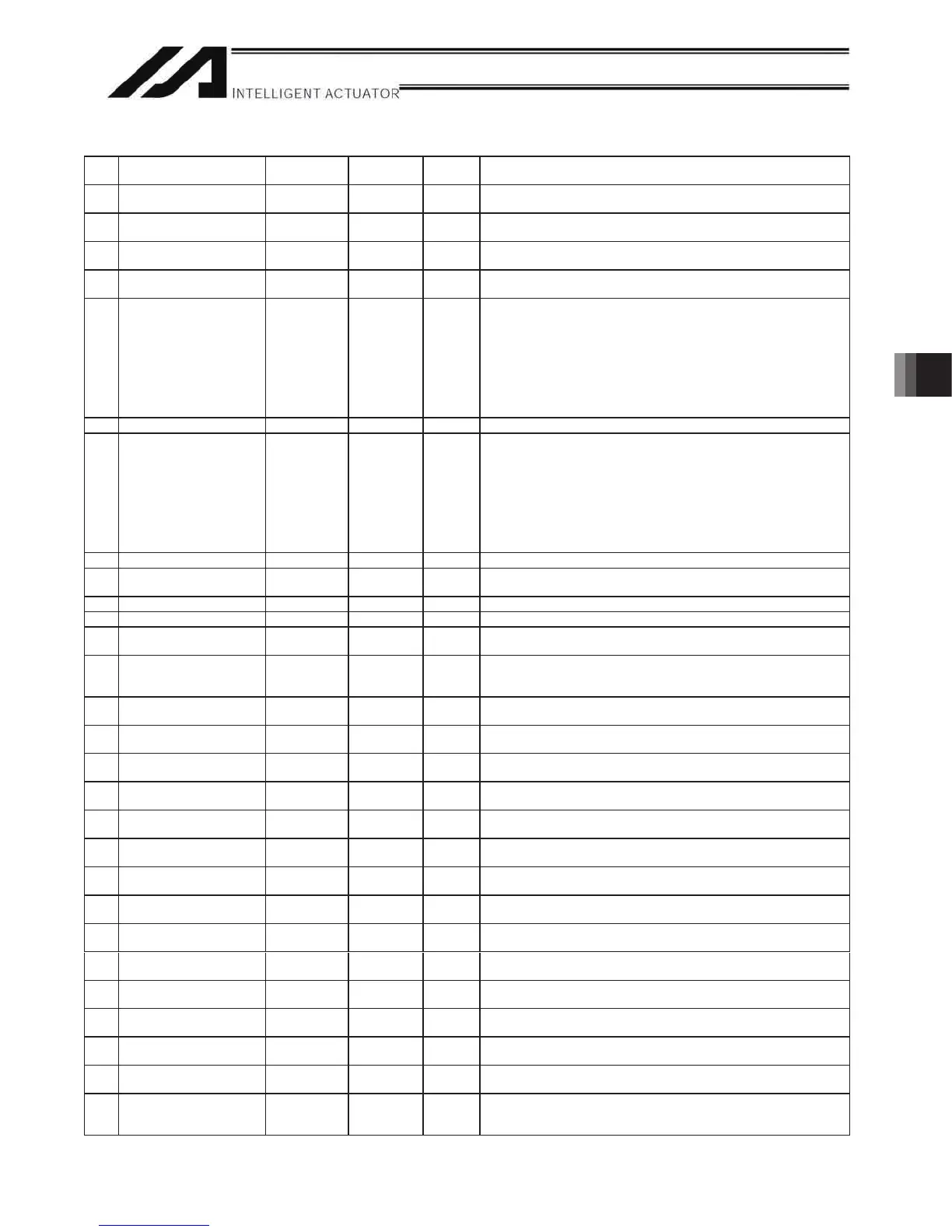

86 Zone 1 MAX 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for at least 3 msec.

87 Zone 1 MIN 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for at least 3 msec.

88 Zone 1 output number 0 0 to 899 Physical output port or global flag (Output is invalid if “0” is input; multiple

specification is invalid)

89 Zone 2 MAX 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for at least 3 msec.

90 Zone 2 MIN 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for at least 3 msec.

91 Zone 2 output number 0 0 to 899 Physical output port or global flag (Output is invalid if “0” is input; multiple

specification is invalid)

92 Zone 3 MAX 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for at least 3 msec.

93 Zone 3 MIN 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for at least 3 msec.

94 Zone 3 output number 0 0 to 899 Physical output port or global flag (Output is invalid if “0” is input; multiple

specification is invalid)

95 Zone 4 MAX 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for at least 3 msec.

96 Zone 4 MIN 0 -99999999 to

99999999

0.001 mm Valid only when MAX > MIN. * Must be inside the range for at least 3 msec.

97 Zone 4 output number 0 0 to 899 Physical output port or global flag (Output is invalid if “0” is input; multiple

specification is invalid)

98 to

100

(For expansion) 0 ~

101 Allowable time for exceeding

continuous-operation enable

torque

0 0 to 300 S If 0, the allowable time for exceeding continuous-operation enable torque is

not monitored.

(Main application version 0.71 or later)

Loading...

Loading...