339

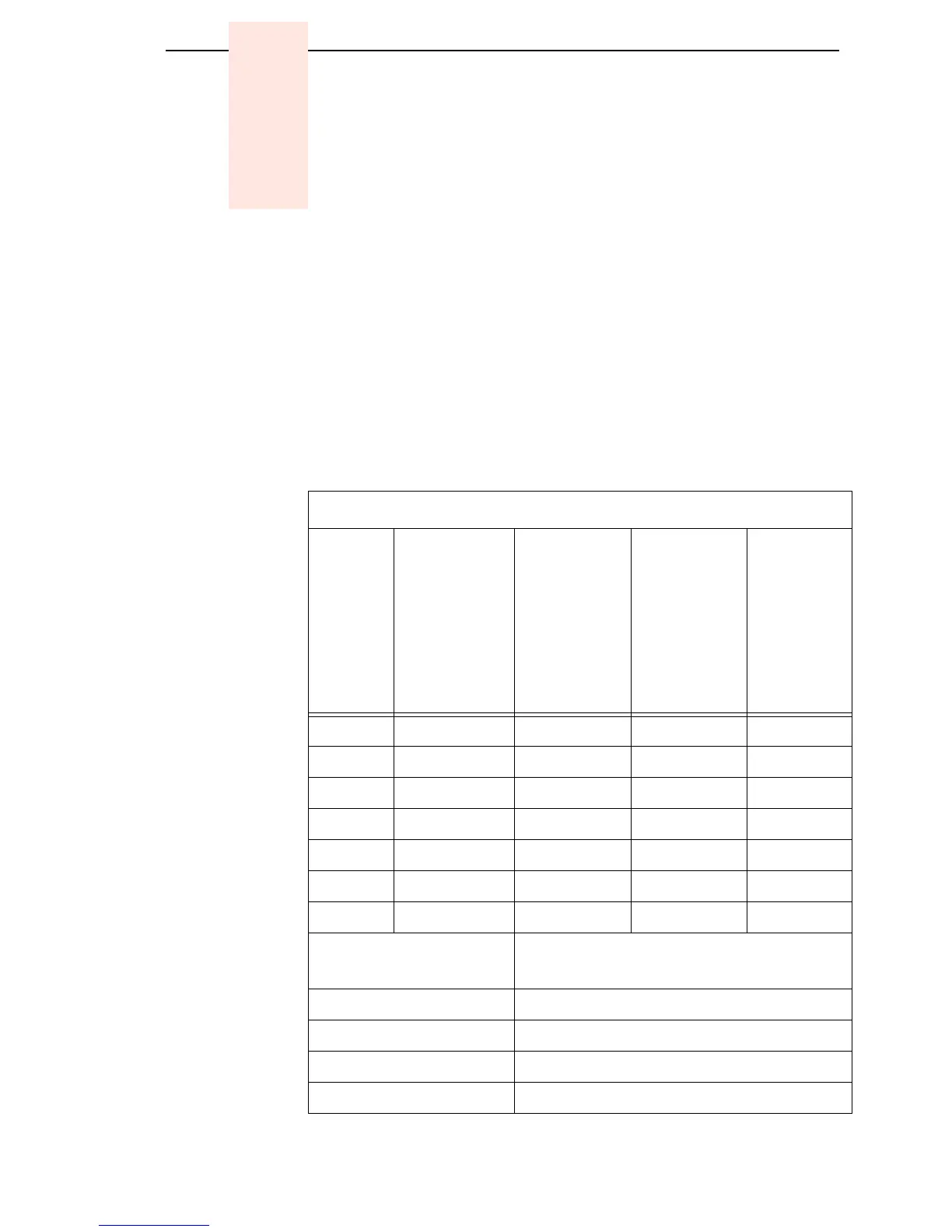

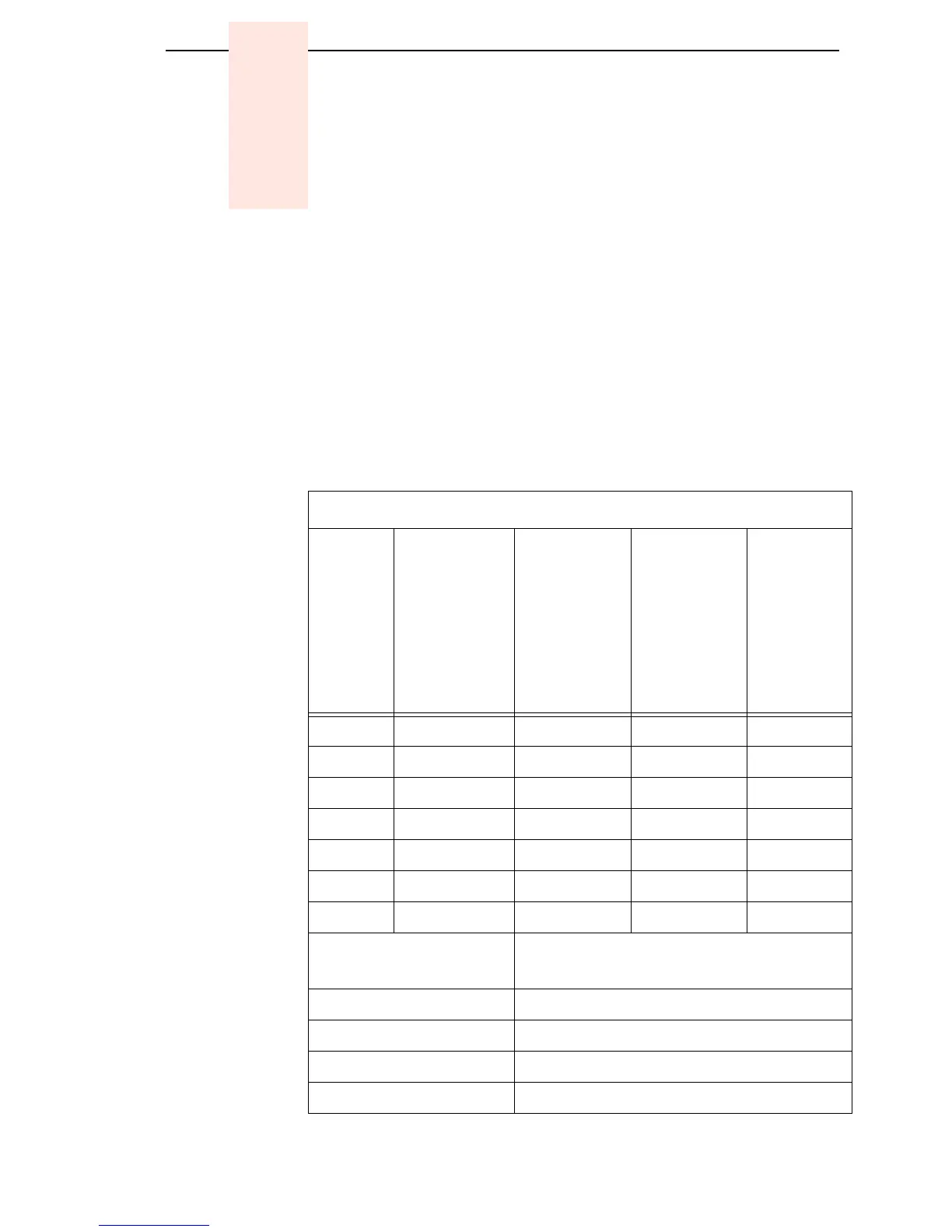

D Torque Table

The table below establishes the torque requirements for routine installation of

threaded fasteners. These requirements apply to fasteners made of steel, at a

minimum engagement of 3.5 threads, including chamfer and countersink. For

the most accurate torquing, apply anti-seize compound to fastener threads

before you torque the fastener.

Fastener sizes are listed as

Numbered Size - Threads Per Inch

. (For

example, 2-56 represents “No. 2 Screw, 56 Threads Per Inch.)

Carbon Steel Fasteners (ANSI B18.6.3 - 1972)

Fastener

Size

Into Alum. or

Brass

25,000 psi

ultimate

tensile

strength

Into Steel

60,000 psi

ultimate

tensile

strength

Into Weld/

Press Studs

or Nuts

Into

Medium

Carbon

Steel

Fasteners

100,000 psi

ultimate

tensile

strength

2-56 25 ± 2 in oz 36 ± 2 in oz 30 ± 2 in oz *

4-40 62 ± 4 in oz 75 ± 5 in oz 70 ± 5 in oz *

6-32 122 ± 7 in oz 150 ± 10 in oz 135 ± 10 in oz *

8-32 11 ± in lb 18 ± 1 in lb 18 ± 1 in lb *

10-24 20 ± 1 in lb 25 ± 1.5 in lb 21 ± 1 in lb *

10-32 15 ± 1 in lb 29 ± 2 in lb 29 ± 1 in lb *

1/4 - 20 40 ± 3 in lb 62 ± 4 in lb 62 ± 4 in lb 105 ± 5 in lb

Fastener Sizes

Torque for Routine Tightening of Threaded

Fasteners

4-40 UNC & 4-48 UNF 4 ± 1 in lb

6-32 UNC & 6-40 UNF 11 ± 1 in lb

8-32 UNC & 8-36 UNF 19 ± 1 in lb

10-24 UNC & 10-32 UNF 25 ± 1 in lb

Loading...

Loading...