6. Description of Parameters

- 137 -

■

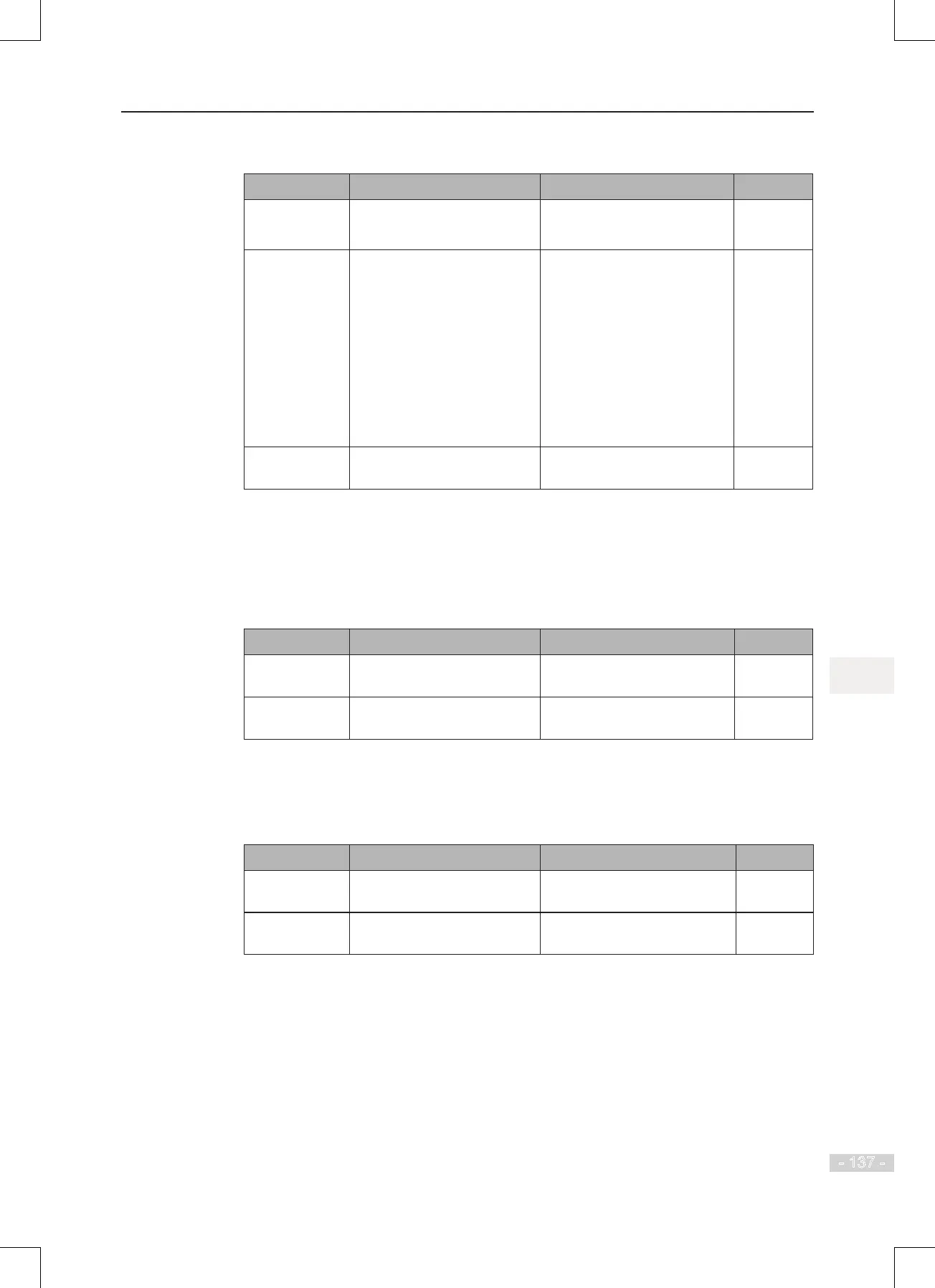

Setting Torque Limit in Torque Control

Function Code Parameter Name Setting Range Default

A0-00

Speed/Torque control

selection

0: Speed control

1: Torque control

0

A0-01

Torque reference source in

torque control

0: Set by A0-03

1: AI1

2: AI2

3: AI3

4: Pulse reference (DI5)

5: Communication reference

6: MIN (AI1, AI2)

7: MAX (AI1, AI2)

0

A0-03

Torque digital setting in

torque control

-200.0% to 200.0% 150.0%

These two function parameters select channel of setting torque reference in torque

control.

Torque reference is a relative value. 100.0% corresponds to rated AC drive torque (can

be viewed in U0-06). When torque reference is a positive value, the AC drive runs in

forward direction. When torque reference is a negative value, the AC drive runs in reverse

direction.

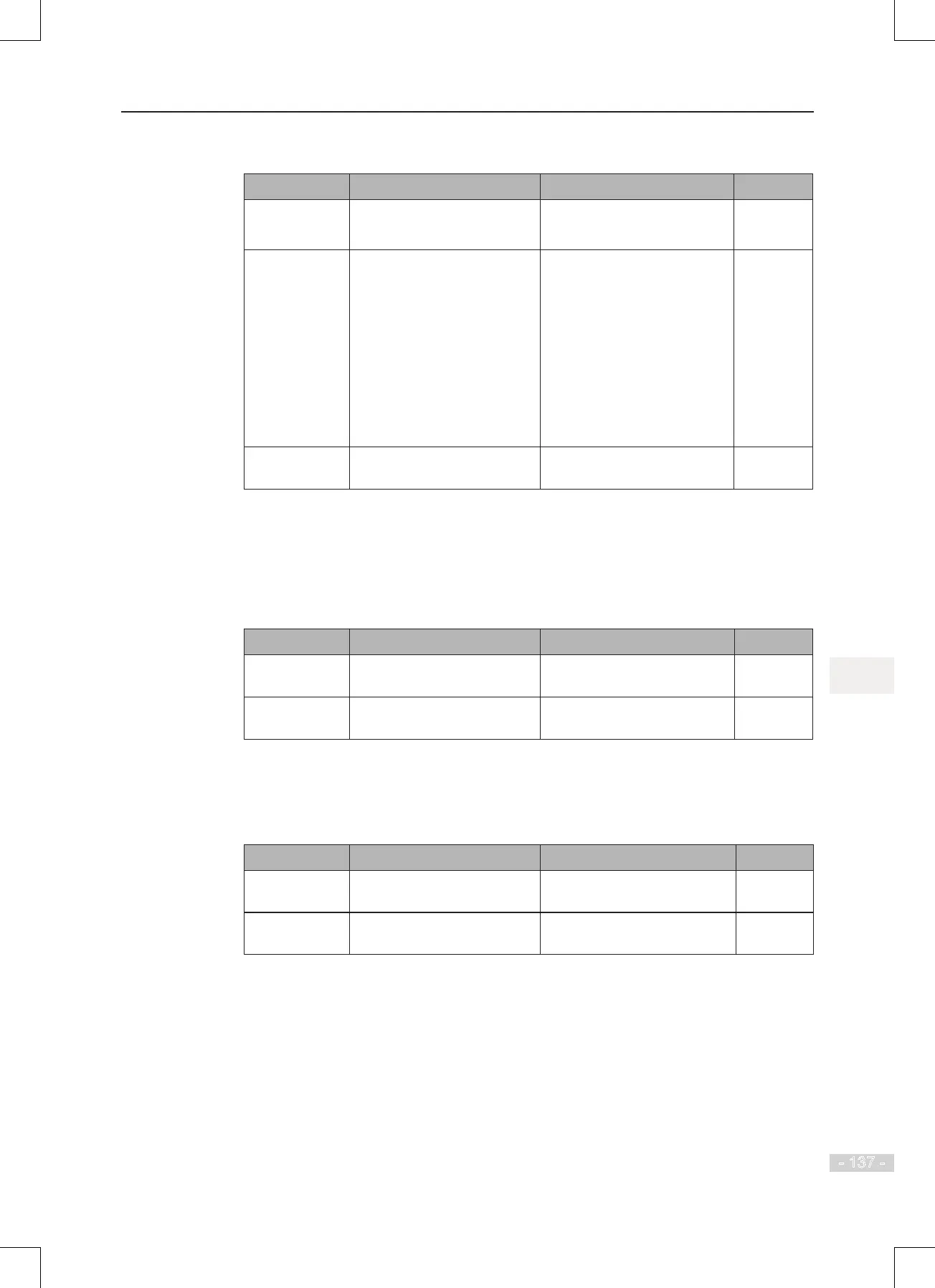

Function Code Parameter Name Setting Range Default

A0-05

Forward max. frequency in

torque control

0.00 Hz to max. frequency

(F0-10)

50.00 Hz

A0-06

Reverse max. frequency in

torque control

0.00 Hz to max. frequency

(F0-10)

50.00 Hz

These function parameters set maximum frequency of the AC drive in forward and

reverse directions in torque control.

Motor speed will rise continuously if load torque is smaller than motor output torque. This

function limits motor speed in torque control to prevent runaway.

Function Code Parameter Name Setting Range Default

A0-07

Acceleration time in torque

control

0.00s to 65000s 0.00s

A0-08

Deceleration time in torque

control

0.00s to 65000s 0.00s

These function parameters set acceleration/deceleration time in torque control to

implement smooth change of motor speed. This helps to prevent problems such as big

noise or too large mechanical stress caused by quick change of motor speed.

But in applications where rapid torque response is required, for example, two motors are

used to drive the same load, you need to set these two parameters to 0.00s.

For example, two motors drive the same load. To balance the load level of the two motors,

set one drive as master in speed control and set the other as slave in torque control.

The slave will follow output torque of the master as its torque reference, which requires

quick response to the master output torque. In this case, set acceleration/deceleration

time of the slave in torque control to 0.00s.

Loading...

Loading...