CHAPTER 4. INSPECTION AND MAINTENANCE OF MAJOR PARTS

107

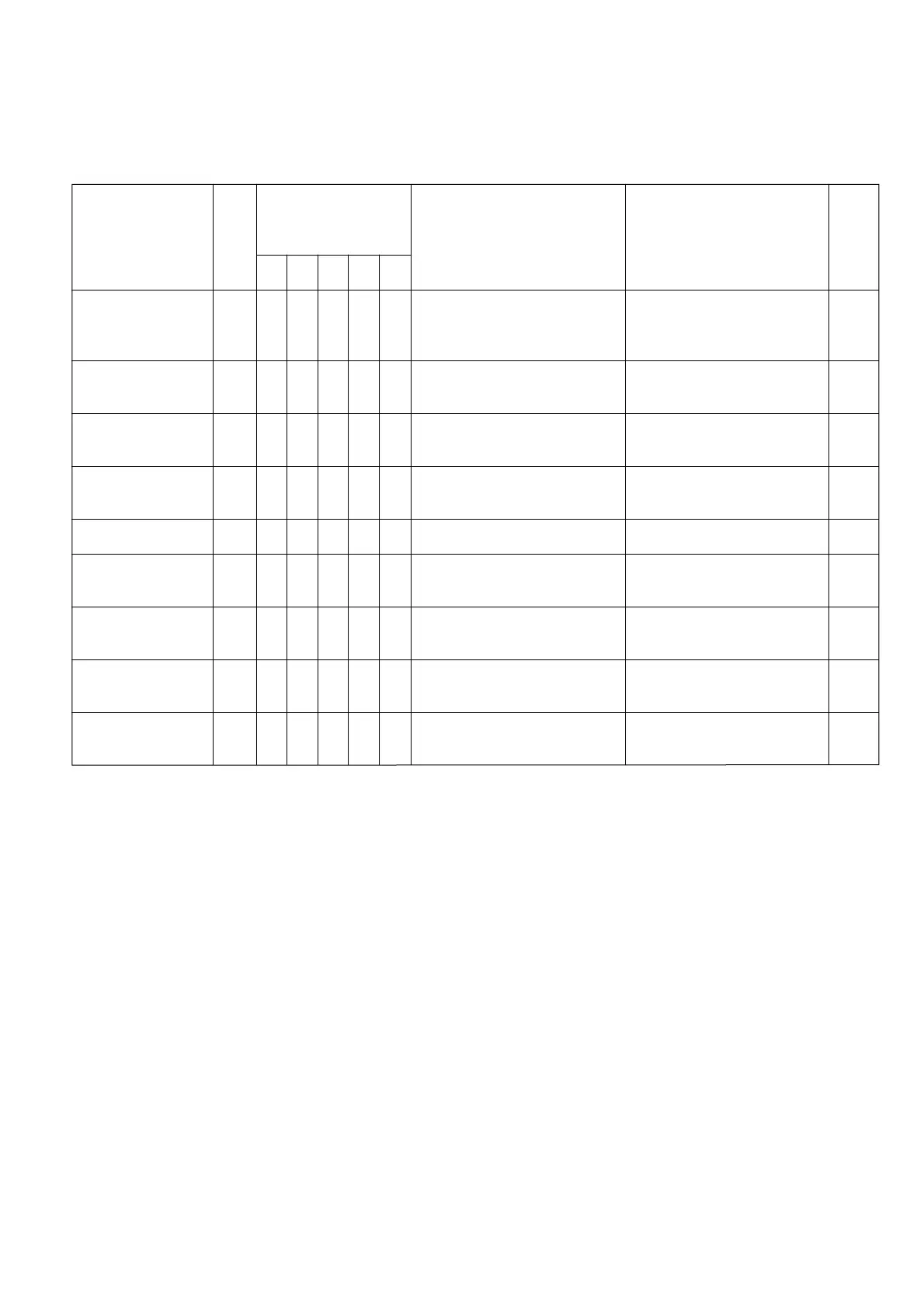

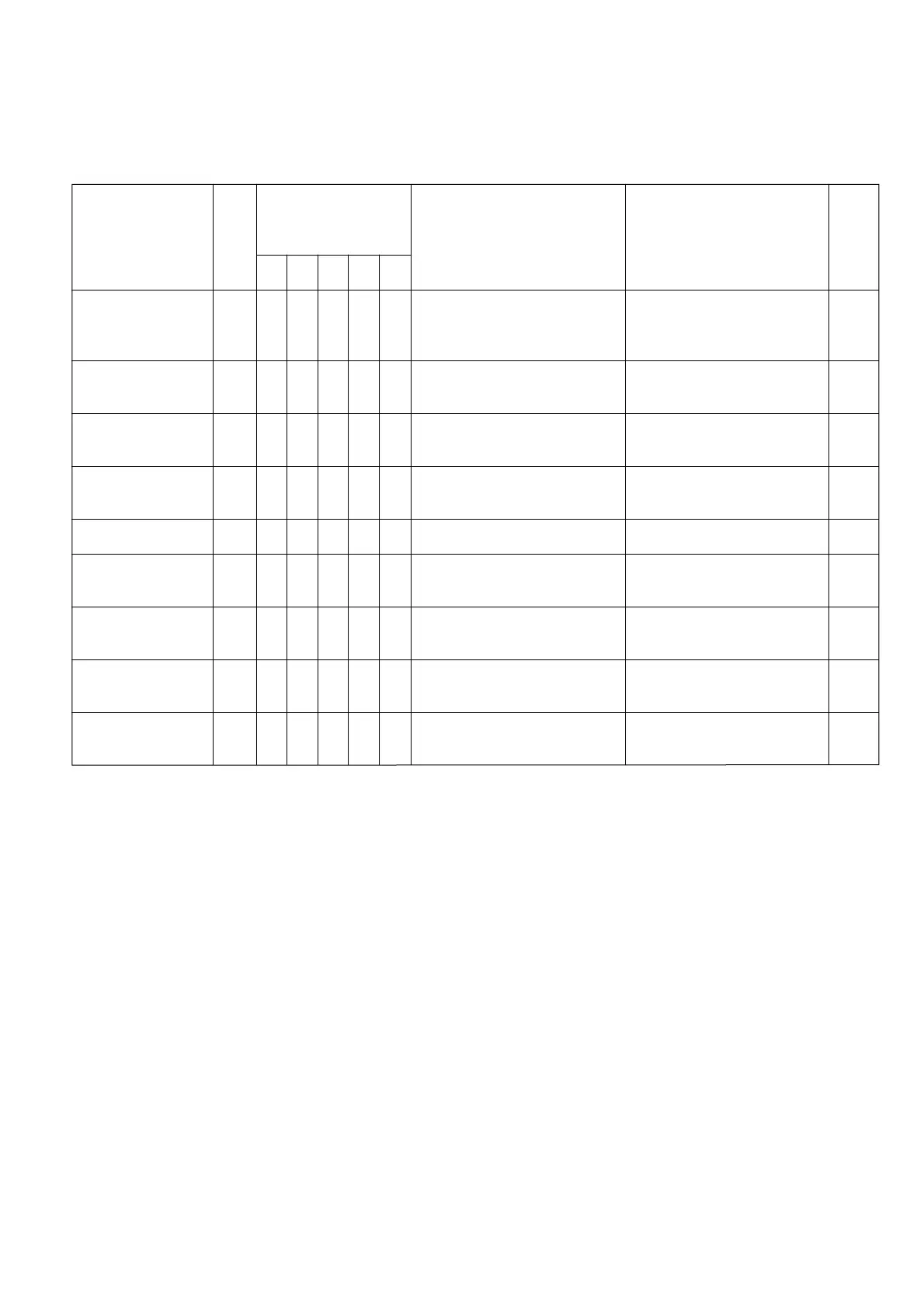

9. PERIODICAL INSPECTION TABLE

IMPORTANT: • Above mentioned service intervals are for normal usage. If working conditions are harder, earlier ser-

vice is recommended.

• If special skill or special tool are required or you feel difficulty in maintenance, consult your dealer.

-

Ref.

page

Judgement criteriaIntervals after that Check points

Inspection and

servicing intervals

(hours of operation)

Pre-

operation

50 100 150 200 250

Blade

Bevel gear case

(LH) and (RH)

Inflation of

gauge wheel

Roller and gauge

wheels

Greasing points

Bolls and nuts

Pins and clips

Belt tension

(SSM54)

Belt cover inside

(SSM54)

Replace oil after initial 50 hrs.

and then after every 200 hrs.

Grease up after every 50 hrs.

Clean after every 50 hrs.

Deformed, broken, worn,

and cracked ones should

be replaced.

Maintain the specified level.

SCMA54: 2.1 kgf/cm

2

SCMB60,SSM54

: 1.5kgf/cm

2

They should turn smoothly.

There should be no loose

ones.

There should be no lost or

deformed ones.

Inter-coil clearance:0.8-1.0

mm (0.03-0.04 in.mm)

There should be no grass or

dust accumulated.

98

102

-

103

103

95

-

104

~

106

: Inspection, replenishment, and adjustment

: Cleaning and washing

: Replacement : Consult your dealer.

Loading...

Loading...