P/N 960-000180R_Rev. 1 {EDP #233427} © 2016, JAPAN CASH MACHINE CO., LTD.

Calibration and Testing DBV® Series DBV-400 Banknote Validator Section 6

Calibration Preparation

Perform the following steps to prepare the DBV-

400 for Sensor Calibration:

1. Remove electrical power from the DBV-400 Unit.

2. Remove the Cash Box from the DBV-400 Unit.

3. Connect the USB Cable to the USB Connector for

maintenance (Refer to Figure 6-1 and Figure 6-2

for the Tool Requirements and Harness Connector

locations).

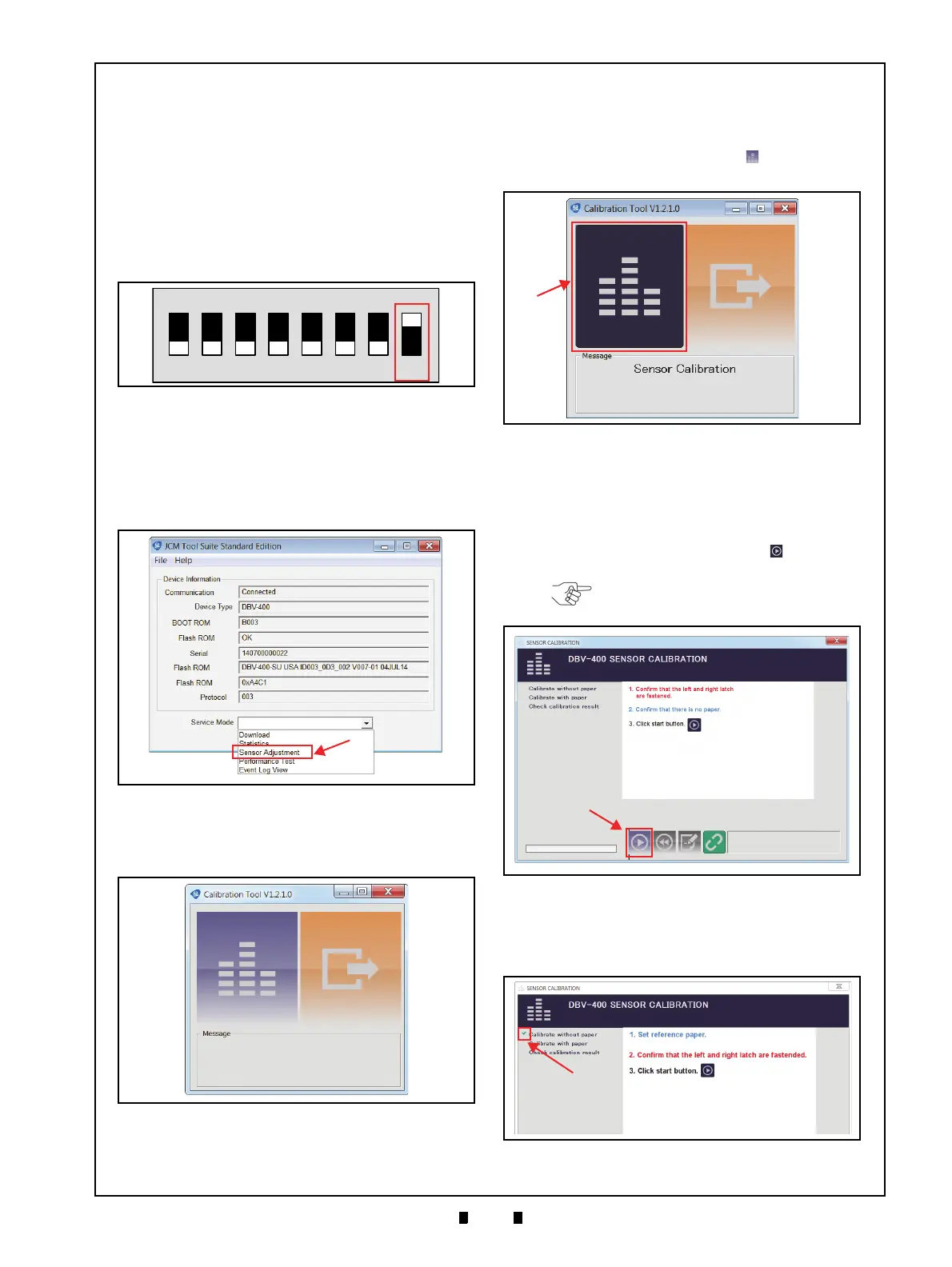

4. Set DIP Switch #8 to

ON (Figure 6-30).

5. Apply electrical power to the DBV-400 Unit. The

Bezel LED will flash a Green color rate.

6. Launch the “

JCM Tool Suite Standard Edition”

Application (Figure 6-31), then click the “

Service

Mode

” Pull-Down Menu, and select “Sensor

Adjustment

” (Figure 6-31 a).

7. Confirm that the Sensor Calibration Program

Screen appears (Figure 6-32).

Sensor Calibration

To calibrate the DBV-400 sensors, proceed as

follows:

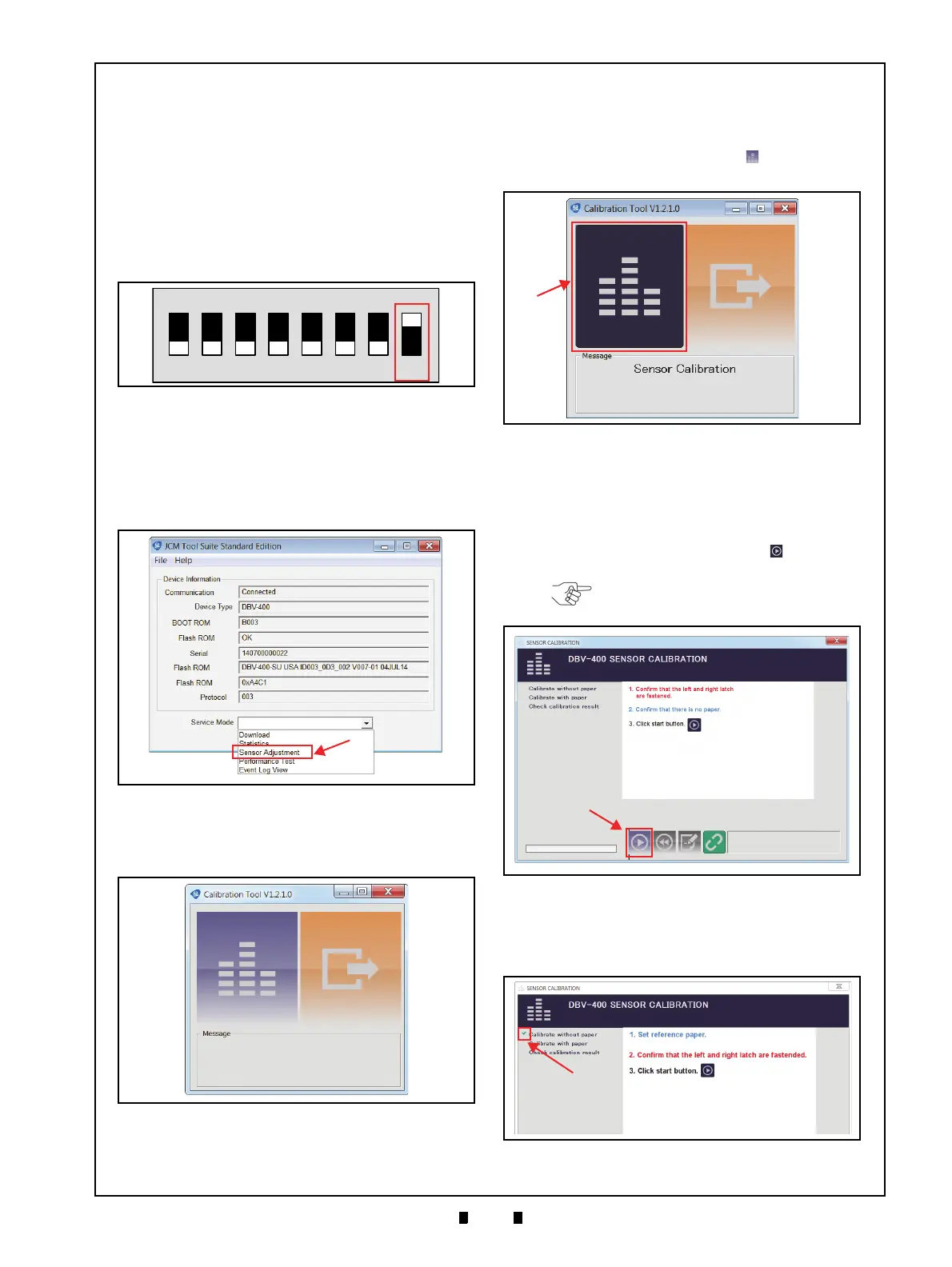

1. Click the “Sensor Calibration” button (Figure

6-33 a).

2. Confirm that the “

DBV-400 SENSOR

CALIBRATION

” Screen appears (Figure 6-34).

3. Make sure the Validation Guide Open/Close

Latch (refer to Figure 1-4 n) is Closed (securely

latched in the Down position on both the left and

right sides). Then click the “

Start” button

(Figure 6-34 a) to begin the non-paper calibration.

4. Confirm that the non-paper calibration was

completed with a check mark (Figure 6-35 a)

appearing next to the “

Calibration without paper”

text line.

Figure 6-30 DIP SW1 Setting

Figure 6-30 DIP SW1 Setting

Figure 6-31

Launching JCM Tool Suite Stan-

dard Edition/Sensor Adjustment

Figure 6-31 Launching JCM Tool Suite Standard

Edition/Sensor Adjustment Selection

Figure 6-32 Sensor Calibration Screen 1

Figure 6-32 Sensor Calibration Screen 1

Figure 6-33 Sensor Calibration Screen 2

Figure 6-33 Sensor Calibration Screen 2

NOTE: Make sure there are no

foreign objects in the Transport Path.

Figure 6-34 Non-Paper Calibration Screen

Figure 6-34 Non-Paper Calibration Screen

Figure 6-35 Non-Paper Calibration Com-

Figure 6-35 Non-Paper Calibration Completion

Loading...

Loading...