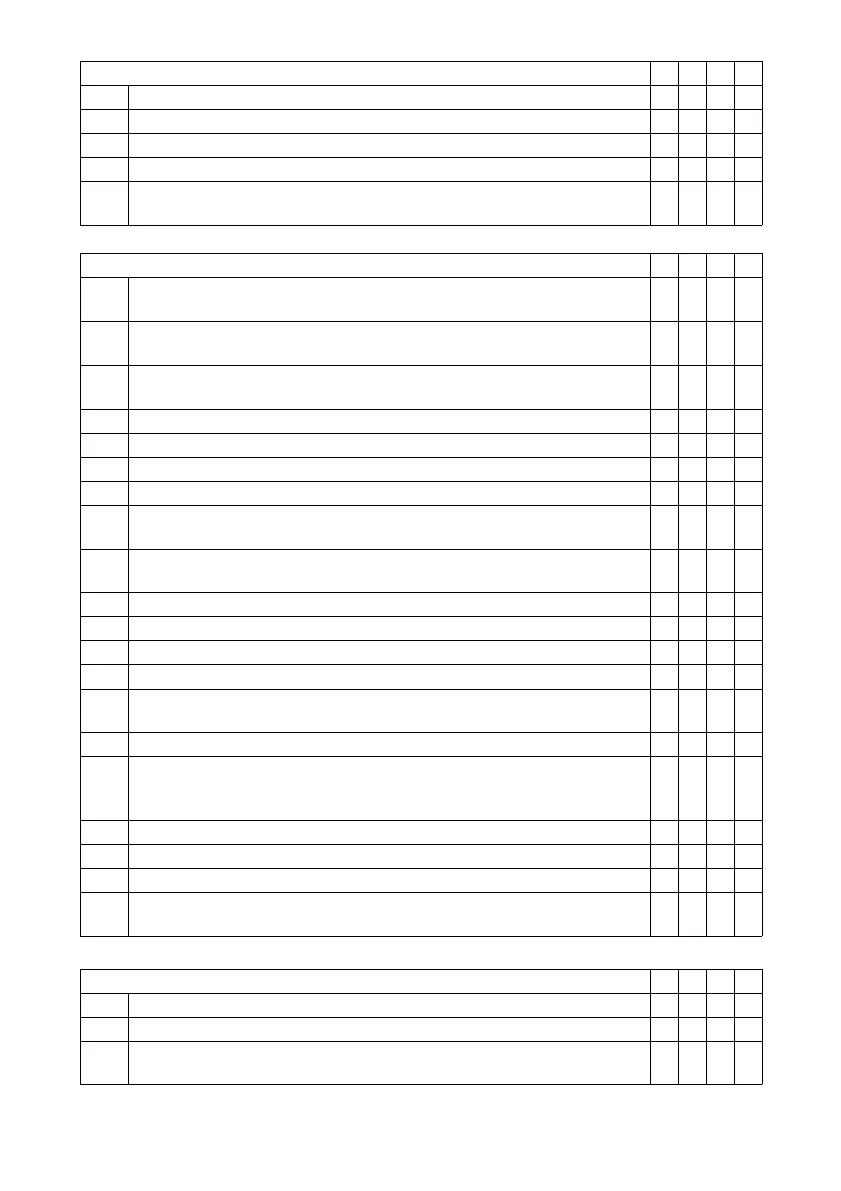

141

08.11 EN

Check chassis and screw connections for damage. t

Check trailer coupling or tow mechanism stop. t

Check attachment and setting function of the driver's seat. t

Check operator mat and steps are non-slip and damage-free. t

Check engine compartment for contamination and clean if

necessary.

t

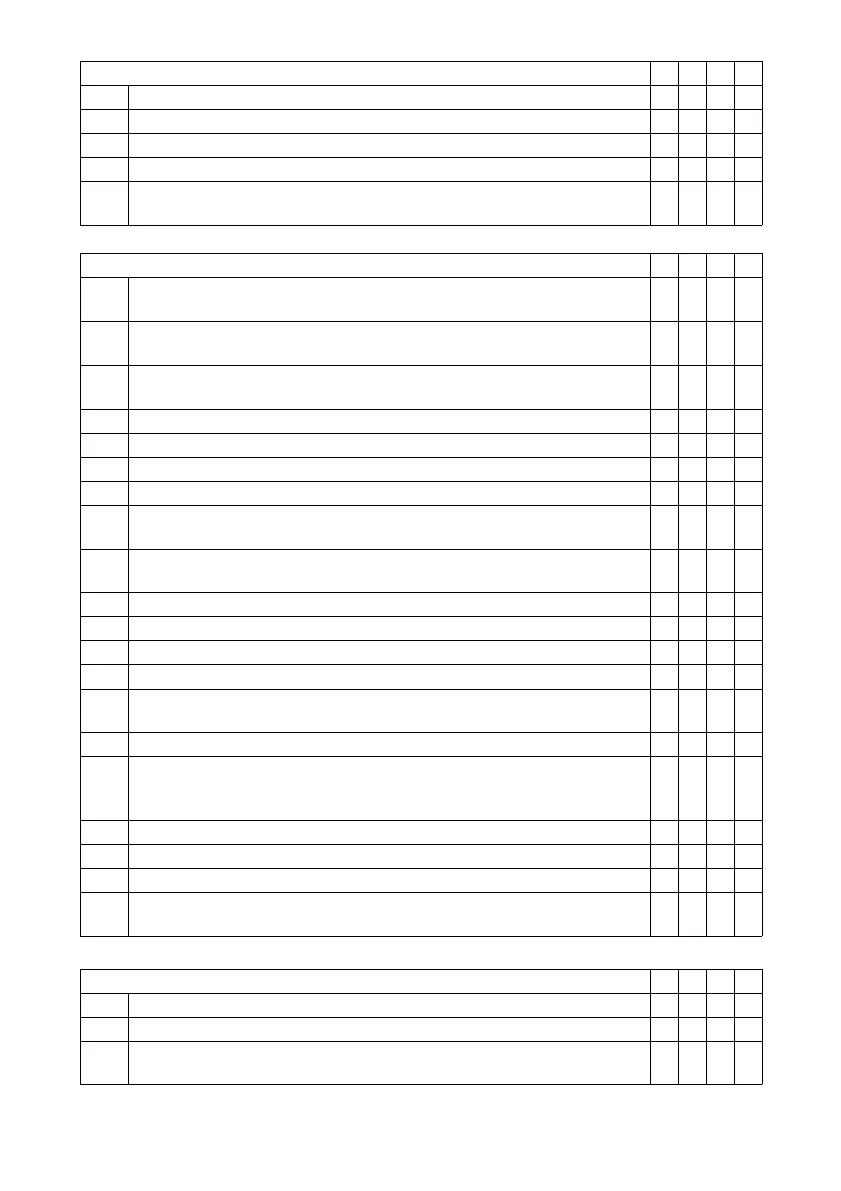

Hydraulic operations W A B C

Check settings and wear levels of slide pieces and stops and adjust

the slide pieces if necessary.

t

Visually inspect the mast rollers and check contact surface wear

level.

t

Check lateral clearance of the mast connections and the fork

carriage.

t

Check load chain setting and tension if necessary. t

Check forks or load handler for wear and damage. t

Check mast tilt. t

Test hydraulic system. t

Check that hydraulic ports, hose and pipe lines are secure, check for

leaks and damage.

t

Check cylinders and piston rods for damage and leaks, and make

sure they are secure.

t

Check hydraulic oil level and top up if necessary. t

Replace hydraulic oil filter. t

Check tilt cylinders and mounting. t

Replace hydraulic reservoir discharge paper filter. t

Test "hydraulic" controls and make sure the labels are present,

legible and complete.

t

Test lift and lowering speeds. t

Check piston rod screw depth and counter fixing / clamp.

Where two tilt cylinders with the same stroke length are used, check

the setting in respective of each other.

t

Test relief valve and adjust if necessary. t

Replace hydraulic oil. t

Check load chain lubrication and lubricate if necessary. t

Check running surfaces of the mast for wear and damage, and

lubricate if necessary.

t

Agreed performance levels W A B C

Lubricate truck according to the lubrication schedule. t

Demonstration after servicing. t

Carry out a test run with rated load, if necessary with a customer-

specific load.

t

Chassis and superstructure W A B C

Loading...

Loading...