Operation Manual ServoOne Supply Unit

20

ID no.: 1101.21B.6-00 Date:04/2020

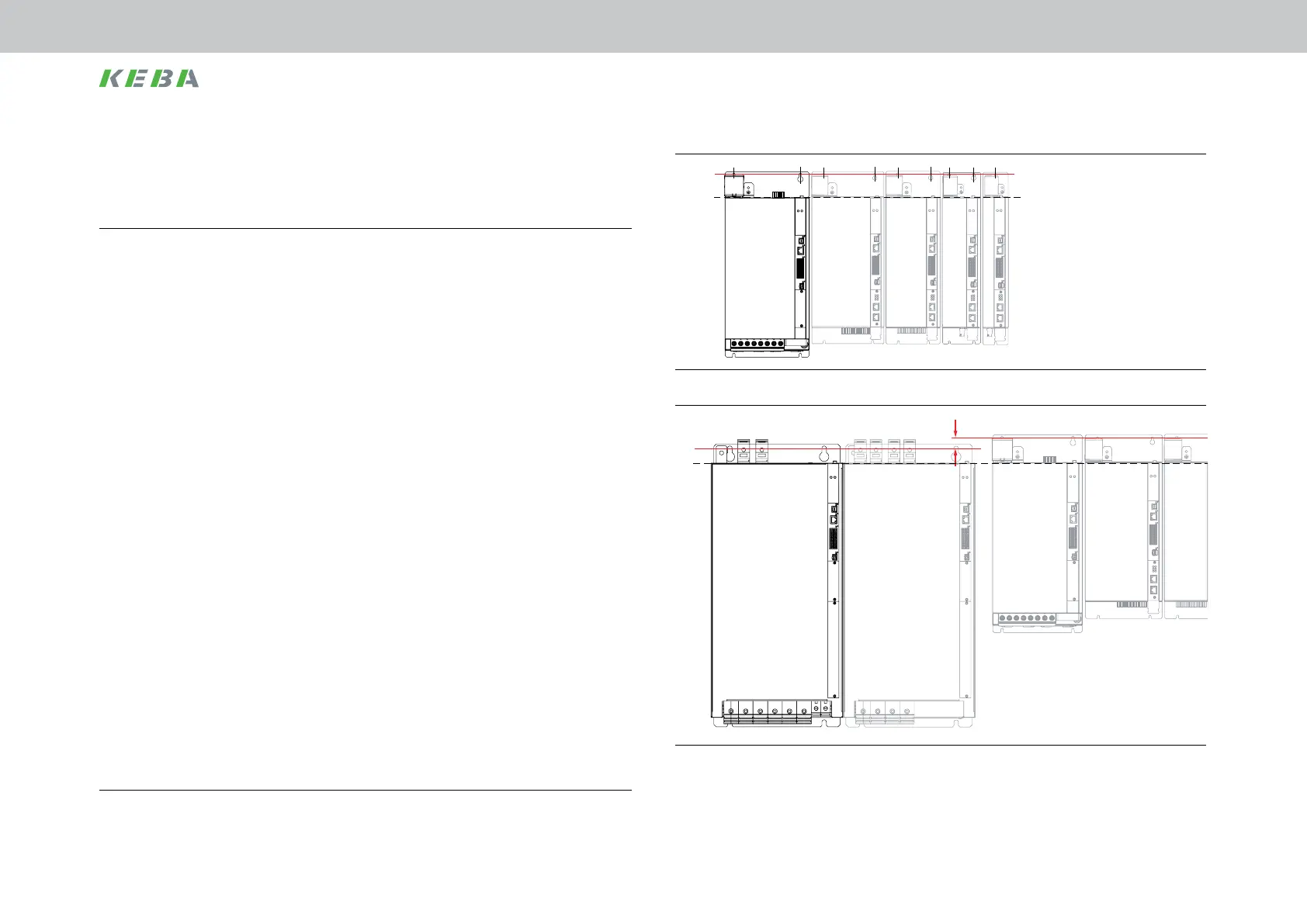

ServoOne DC BG1

ServoOne DC BG2

ServoOne DC BG3

ServoOne DC BG4

ServoOne

Supply unit BG5

B

A

Figure 3.8 Butt mounting axis group with liquid cooling and supply unit BG5

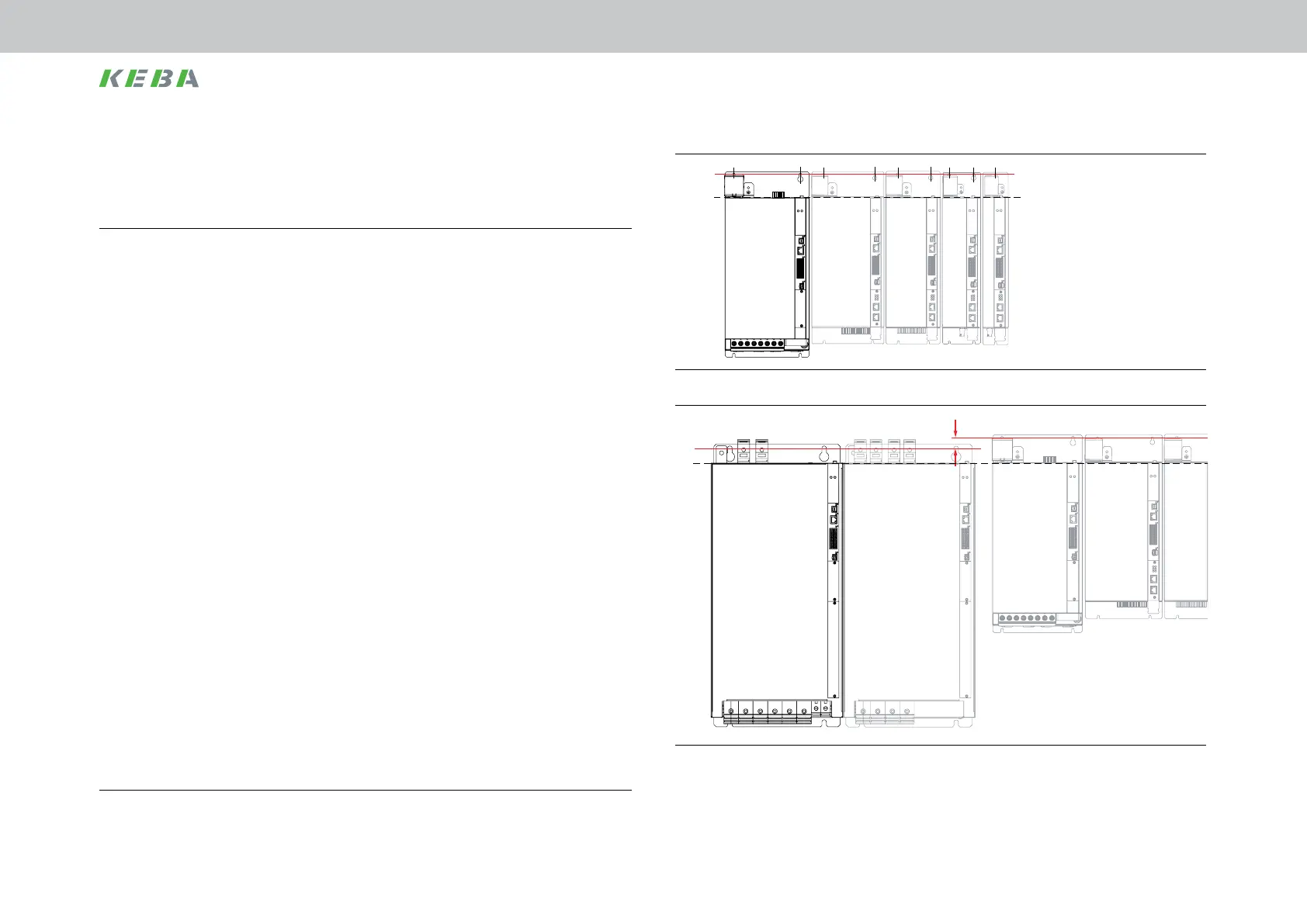

ServoOne DC BG1

ServoOne DC BG2

ServoOne DC BG3

ServoOne DC BG4

ServoOne DC BG5

20 mm

ServoOne DC BG6a

with liquid cooling

ServoOne

Supply unit BG6a

with liquid cooling

B

A

Figure 3.9 Butt mounting axis group with liquid cooling and supply unit BG6a

3.4 Mounting supply unit,

liquid cooling housing variant

1.

Arrange the devices starting from the supply unit to the right (up to ServoOne

DC BG5) or left (from ServoOne DC BG6a) sorted in descending order by power

rating to minimise thermal interaction. Pay attention to the notes on effective EMC

installation prior to mounting the devices and components in the switch cabinet.

• AlignthesupplyunitBG5andallServoOneDCaxiscontrollersinalinealongthetopedge

ofthedevices(seelineAinFigure3.8).ThisactionisnecessarytobeabletosupplytheDC

powerusingthepre-assembledcables.

• AlignallServoOneDCaxiscontrollersandthesupplyunitBG6ainalinealongthetopedge

ofthedevices(seelineAinFigure3.9).MovedownthemountingboresforDCaxiscontroller

BG6aandthesupplyunitBG6byapprox.20mm(seeredlineBinFigure3.9).Thisactionis

necessarytobeabletomaketheDClinkconnections.

• AlignallServoOneDCaxiscontrollersandthesupplyunitBG7inalinealongthetopedge

ofthedevices(seelineAinFigure3.10).Movedownthemountingboresforthesupplyunit

BG7byapprox.28mmandfortheDCaxiscontrollerBG6abyapprox.20mm(seeredline

BinFigure3.10).Inaddition,adistanceof≥40mmmustbemaintainedattheside(inthe

guretotherightofthesupplyunitBG7).ThisactionisnecessarytobeabletomaketheDC

linkconnection.

2.

Mark out the position of the tapped holes and the pipe ttings on the backing plate.

Drill holes and cut a thread for each xing screw in the backing plate.

Note the mounting distances. Also pay attention to the bending radius of the

connection cables. For dimensional drawings/hole spacings see Figure 3.8 to

Figure 3.10 and Table 3.2.

3.

Mount the supply unit vertically and butt-mounted in a row on the backing plate.

The contact area must be bare metal.

4.

On screwing the hose connections (not included in the scope of supply) into the

pipe ttings, lock the pipe ttings using a 22mmopen-ended wrench to prevent

damage due to the application of torque to the device.

Pay attention to a perfectly sealed connection without leaks (e.g. using Teon

sealing tape).

You will nd further notes on the liquid cooling in chap.A.4, p.80.

Mechanical installation

Loading...

Loading...