Issue: 08/2012

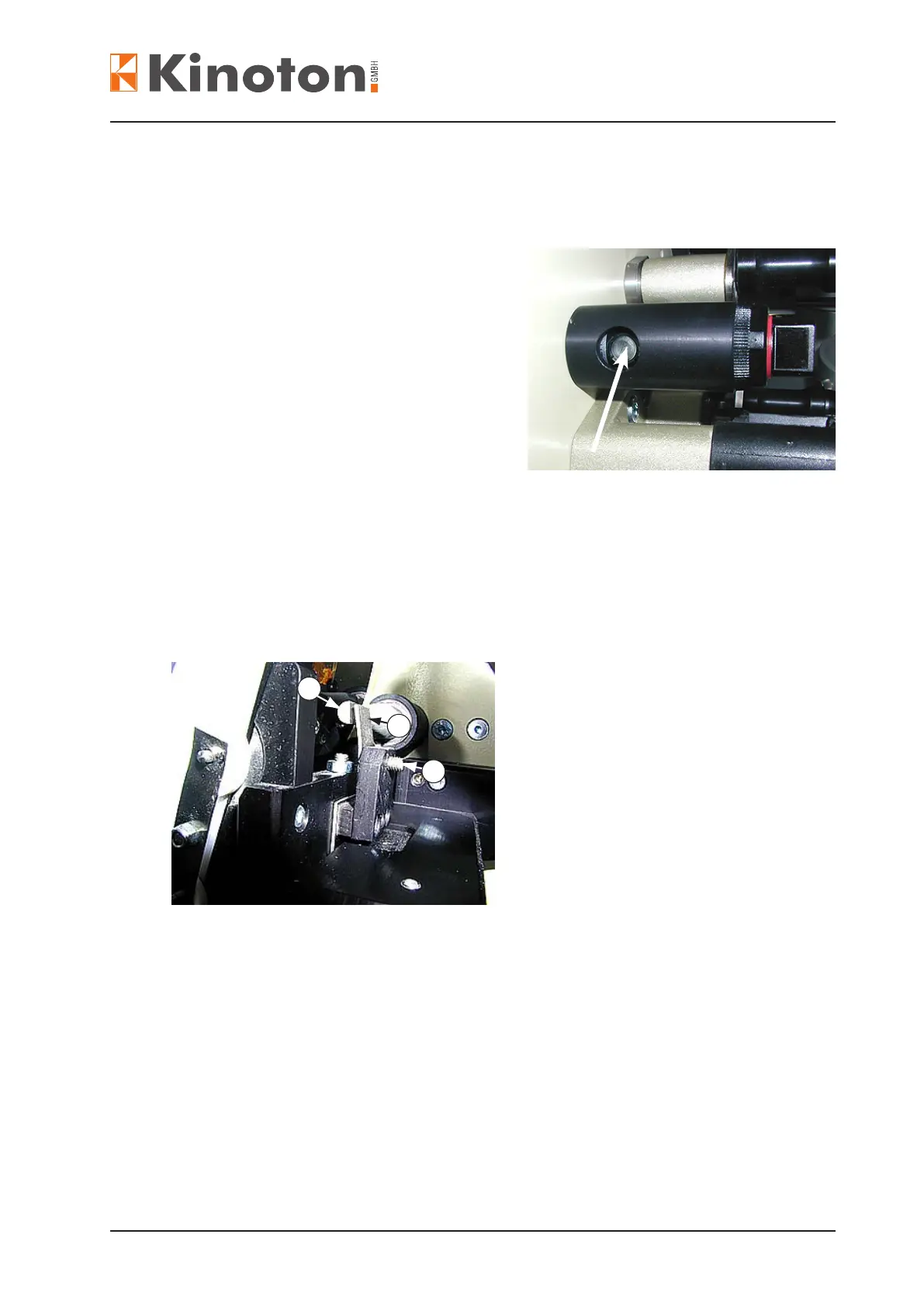

Position the sensor (arrow) in a way that it “looks” vertically towards the lm surface.

The sensor’s view must be perpendicular to the lm.

• To adjust the sensitivity of the sensor

thread a lm and turn the plastic screw

(arrow) with a screw driver until the red

LED (adjusting aid) blinks.

• Then turn the screw until the LED surely

lights steadily.

• Switch on the projector.

$As soon as the boot phase is nished, the skate lifting will be activated. From this

moment on the correct function can be checked or adjustments can be carried out.

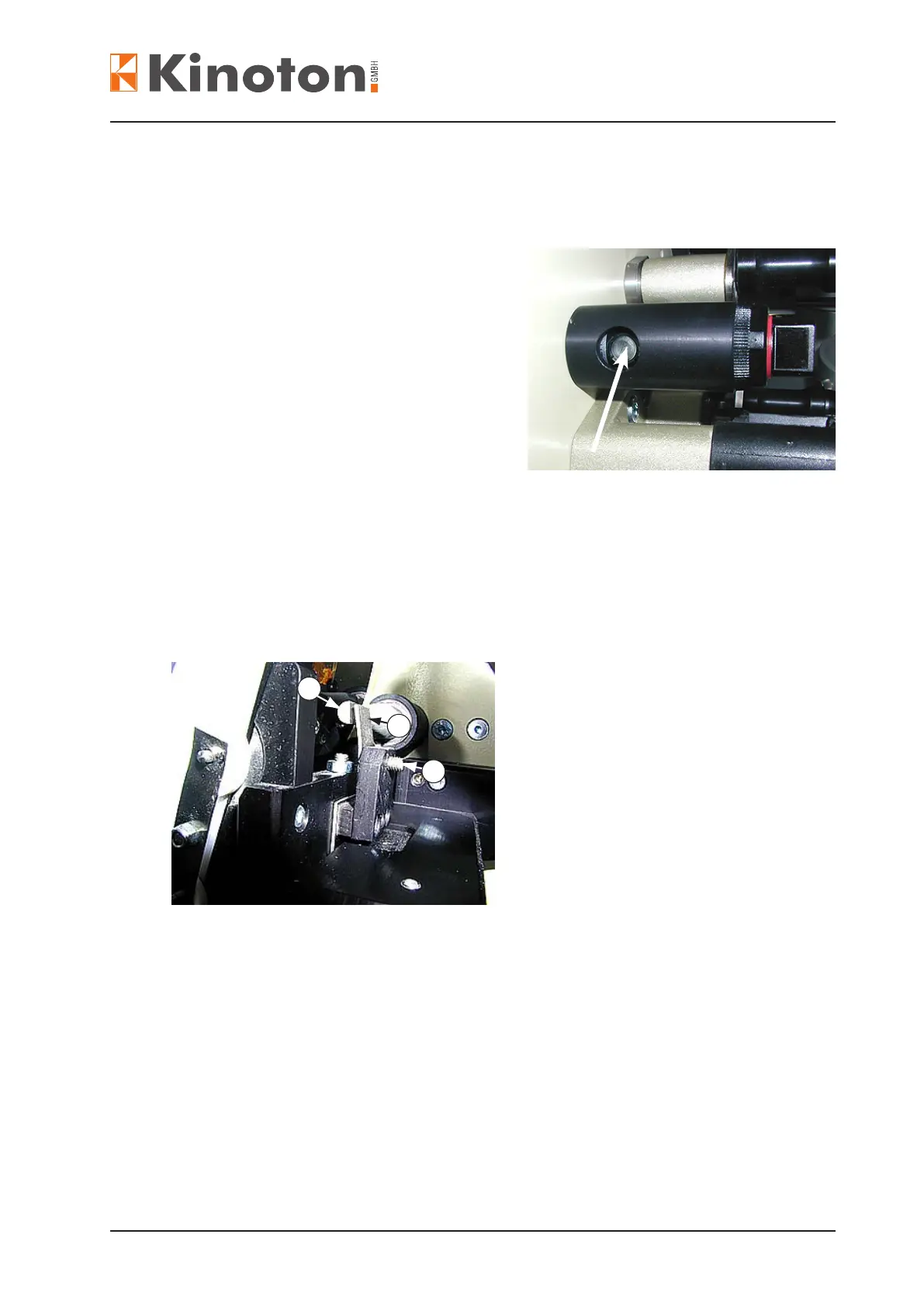

1

2

3

$The skate lifting device essentially consists of a rotation shaft with a at side which

is driven by a solenoid.

$When active the round side of the shaft presses against a metal plate Á and releases

the pressure from the lm (the skate is lifted).

$When not active the at side of the shaft points towards the metal plate, but does not

touch it - pressure is exerted on lm.

$When the skate is lifted (reverse running or pausing) the gap between the skate and

the runners should range between 0.5 and 1 mm in the area of the upper ceramics

roller.

• The skate lifting can be adjusted by turning the grub screw  (Allen key 2).

The contact areas of the shaft and the plate should be slightly greased.

Repair and Adjustments

Loading...

Loading...