Issue: 08/2012

The intermittent sprocket is a very

precise sprocket. It transports the lm step

by step through the lm gate.

The intermittent sprocket is driven directly

via the intermittent sprocket motor.

The projector is equipped with a combined

intermittent sprocket for transporting 35 mm

and 70 mm lms.

Framing is done electronically controlled.

X

An adjustment can only be carried out by experts.

You can adjust the frame by pushing the

or button.

As long as you are pressing one of these buttons, the motor of intermittent sprocket

will move the frame up or down.

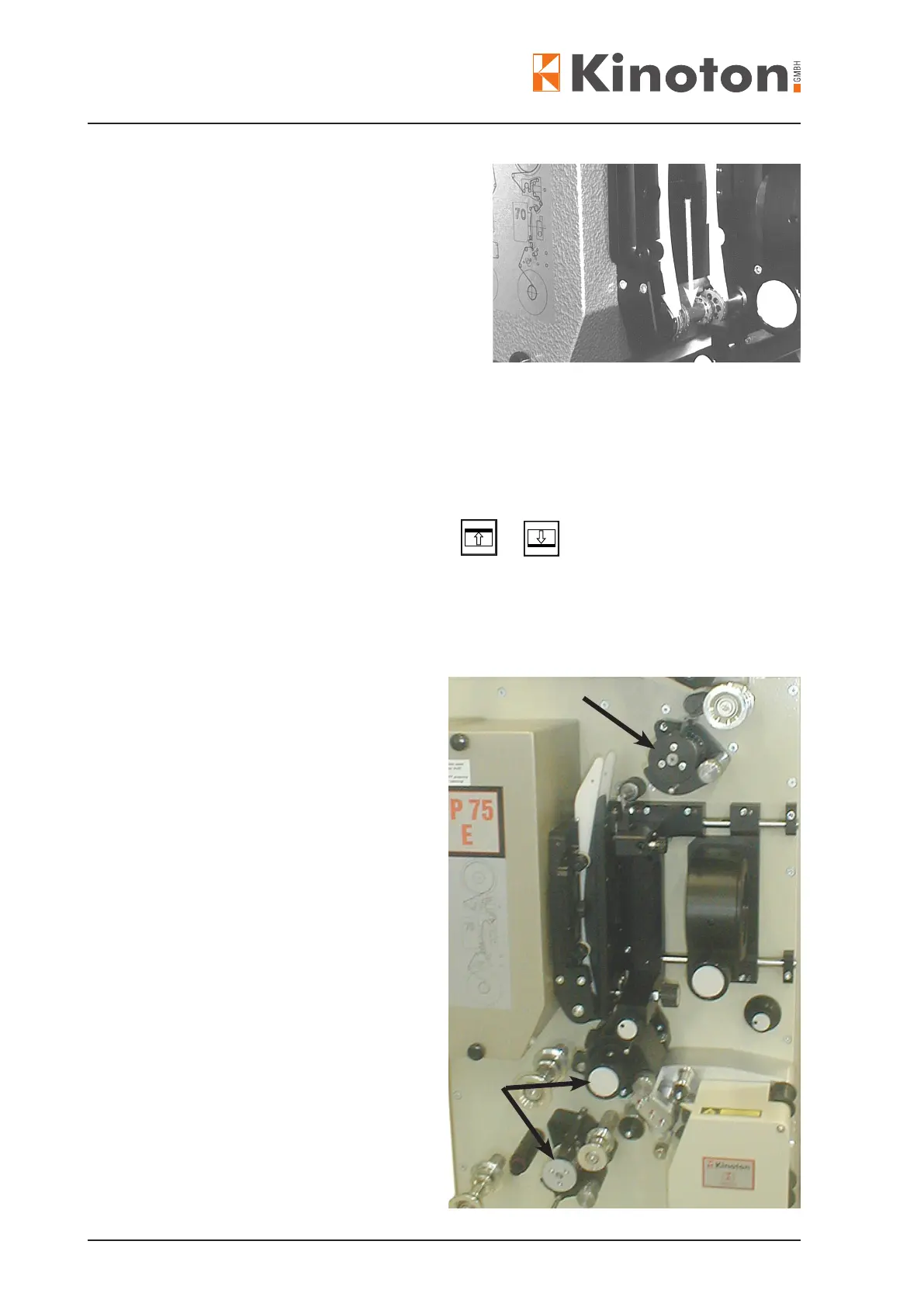

Sprockets (arrows) are designed to

transport the lm continuously. The

teeth of the sprocket engage the lm

perforations. Both sprockets provide

for equal loops before and after the

lm gate.

$The combined upper feed sprocket

pulls the lm from the take-off

friction or from the platter system to

the lm gate.

$The combined bottom sprocket

pulls the lm out of the lm gate

and feeds the 70 mm lm to the

take-up friction or to the platter

system and the 35 mm lm to the

reverse-scan sound device.

$The 35 mm bottom sprocket pulls

the lm out of the reverse-scan

sound device and feeds it to the

take-up friction or to the platter

system.

Loading...

Loading...