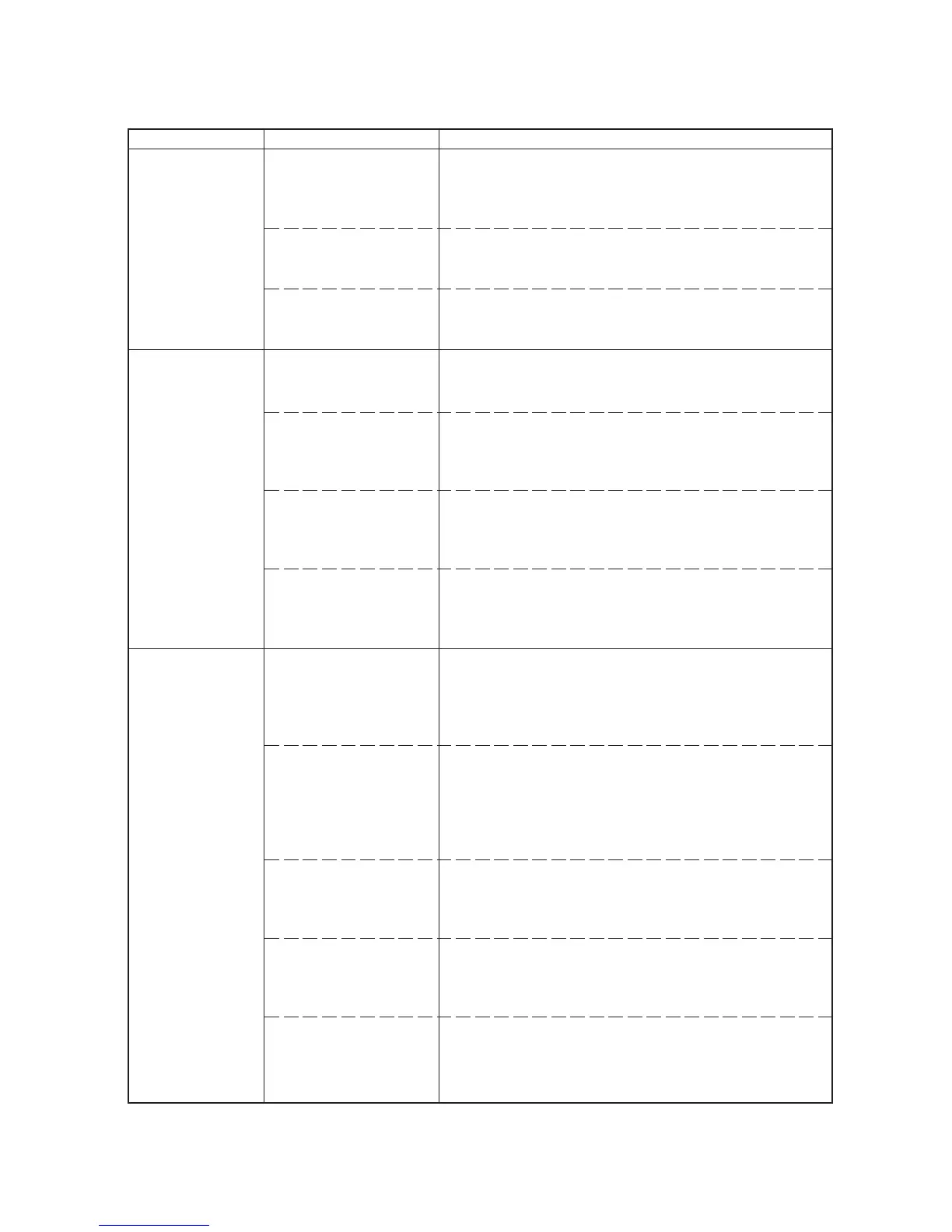

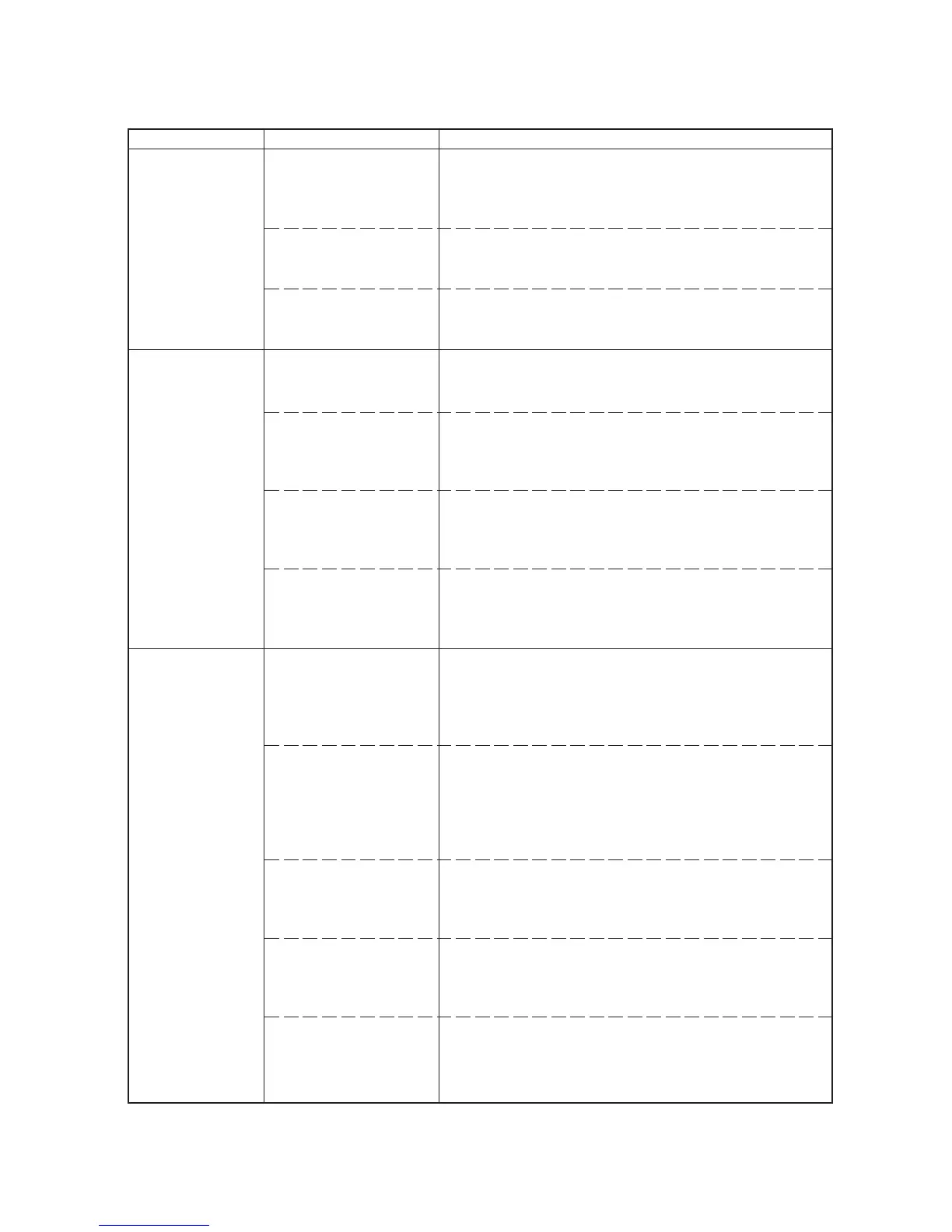

2FP/2FY/2FR-2

1-5-21

(1) Defective waste

toner box detecting.

• Although new

waste toner box is

installed, Check

waste toner box is

displayed. Al-

though waste

toner bottle is not

installed, Ready is

displayed.

(2) Defective paper

jam detecting.

• Paper jam fre-

quently occurs.

• False paper jam

message display.

(3) Defective paper

gauge sensing.

• False paper gauge

indication.

Defective waste toner full

sensor [board] (KP-1065)

or waste toner sensor (re-

ceiver).

Deformed pins of connec-

tor (YC702) on the sensor

board (KP-1077).

Defective engine board

(KP-1081).

Surface of the registration

sensor (PH701) is dirty

with paper particles.

Actuators of registration

sensor (PH701) or exit

sensor does not operate

smoothly.

Defective sensor board

(KP-1077), fuser board

(KP-1069) or engine board

(KP-1081).

A piece of paper torn from

a sheet is caught around

actuator of registration

sensor or exit sensor.

Surface of the paper

gauge sensor 1 (PH702)

and 2 (PH703) on the sen-

sor board (KP-754) are

dirty with paper particles.

A piece of paper torn from

a sheet is caught around

paper gauge sensor 1

(PH702) and 2 (PH703) on

the paper sensor board

(KP-754).

Reflecting mirror has come

off the actuator of paper

gauge sensor 1 (PH702)

and 2 (PH703).

Defective paper gauge

sensor 1 (PH702) and 2

(PH703) on the sensor

board (KP-754).

Defective engine board

(KP-1081).

Replace drum unit. See page 1-6-10.

Check and straighten pins of connector (YC702) on the sensor

board (KP-1077).

Replace engine board (KP-1081).

Clean with cloth.

Repair or replace.

Replace sensor board (KP-754), fuser board (KP-1069), or en-

gine board (KP-1081). See page 5-26 and 1-6-20.

Check visually and remove it, if any.

Clean with cloth.

Check visually and remove it, if any.

Check visually and remove it, if any.

Replace sensor board (KP-1077). See page 1-6-24.

Replace engine board (KP-1081). See page 1-6-20.

1-5-4 Electrical problems

Problem Causes Check procedures/corrective measures

Loading...

Loading...