5 Motor control & motor settings

5.10 Synchronous motor (SM): Pole position identification

111

Lenze · i700 servo inverter · reference manual · DMS 3.0 EN · 06/2016 · TD06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

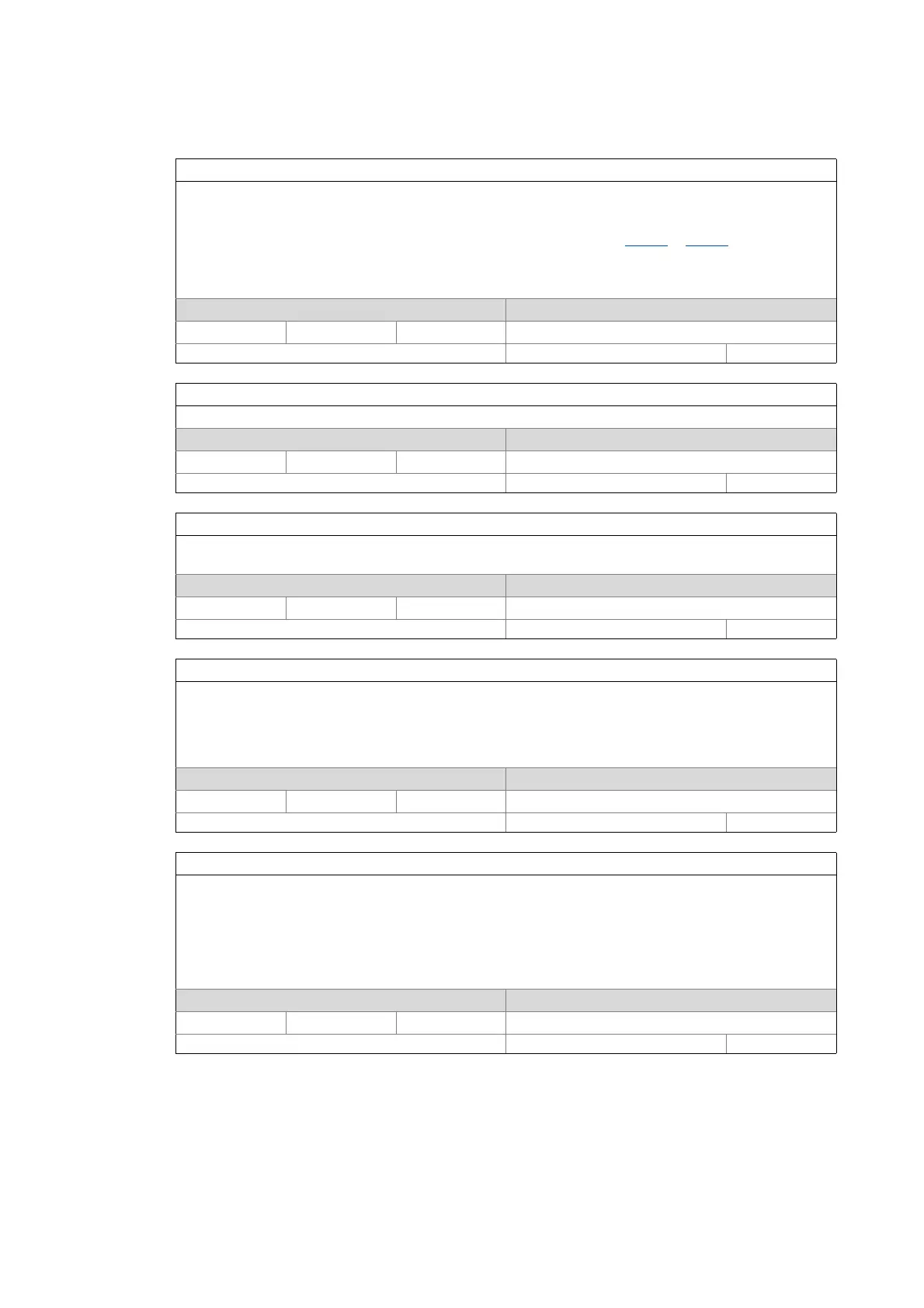

Subindex 1: PPI (min. movement): Current amplitude

Adjustment of the current amplitude in percent

• For large machines and high mass inertia values or for linear direct drives, the current amplitude usually has to

be increased.

• A Lenze setting of "100 %" corresponds to 35 % of the rated motor current (0x6075

or 0x6875 for axis B).

Note!

If the current amplitude is set to > 400 %, the device utilisation (Ixt) monitoring and/or one of the motor monitoring

functions may respond and cause the abort of the pole position identification.

Setting range (min. value | unit | max. value) Lenze setting

1 % 1000 25 %

Write access CINH OSC P RX TX UNSIGNED_16

Subindex 2: PPI (min. movement): Ramp time - current

Adjustment of the rate of rise of the current in percent

Setting range (min. value | unit | max. value) Lenze setting

1 s 600 10 s

Write access CINH OSC P RX TX UNSIGNED_16

Subindex 3: PPI (min. movement): Gain

Adjustment of the proportional gain of the PI controller

• With the Lenze setting "0", the PI controller works as an I-controller.

Setting range (min. value | unit | max. value) Lenze setting

0 % 1000 0 %

Write access CINH OSC P RX TX UNSIGNED_16

Subindex 4: PPI (min. movement): Reset time

Adjustment of the PI controller reset time

• For this, observe the following setting details:

• In order to be able to compensate a positional variation faster, first the reset time should be reduced. If this

does not result in the desired behaviour, the proportional gain can be increased.

• Ensure that the position control does not get unstable. We therefore recommend to use an I controller.

Setting range (min. value | unit | max. value) Lenze setting

0.1 ms 6000.0 62.5 ms

Write access CINH OSC P RX TX Scaling: 1/10 UNSIGNED_16

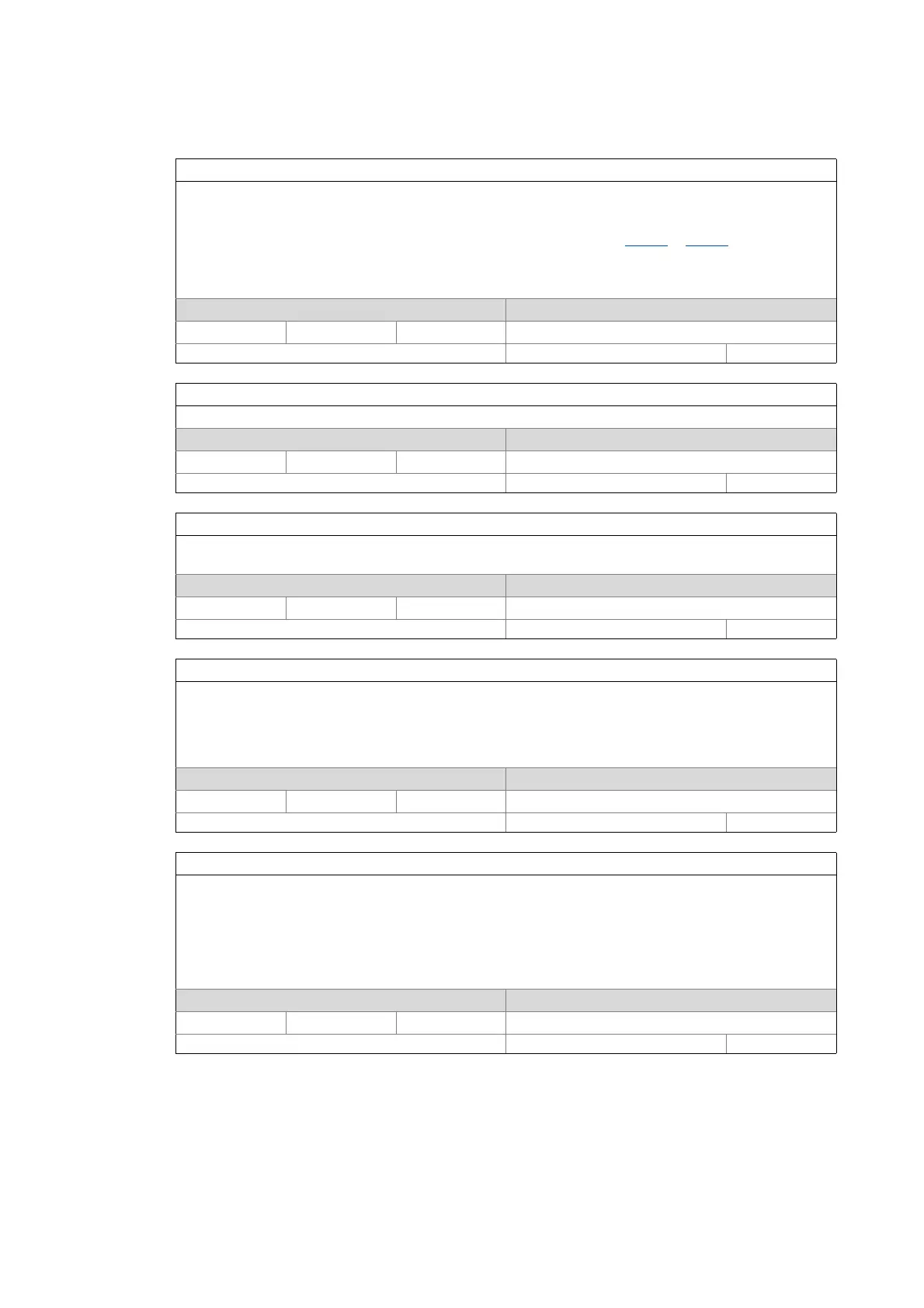

Subindex 5: PPI (min. movement): Max. move permitted

Adjustment of the permitted movement

• The pole position identification comprises a monitoring function for the follow-up control. If a movement

greater than the permissible movement set is detected by the encoder system, the pole position identification is

aborted and the error response parameterised is tripped:

• In order to detect a non-permissible blocking of the machine, a positive and negative test angle relative to the

current position are defined after the identification. The machine must align itself to these two test angles

within a tolerance of 25 %. The size of the test angle corresponds to the max. move permitted set here.

Setting range (min. value | unit | max. value) Lenze setting

1 ° 90 20 °

Write access CINH OSC P RX TX UNSIGNED_8

Loading...

Loading...