Page 68 of 295

13. LA40 (MEDLINE

®

CARELINE

®

)

The LA40 is a low noise and powerful actuator which is available in a 1,500 N,

4,000 N, 6,000 N and an 8,000 N version.

With the LA40, LINAK offers a new durable actuator with high speed/high

performance and mechanical endstop for first failure safety making it the right

choice for the future market. The LA40 versions are rated up to IPX6 Washable

DURA

TM

, except for the LA40 PL version which is rated up to IPX6.

The LA40 8,000 N is available in three versions:

- Standard

- High Performance (HP)

- Patient Lift (PL)

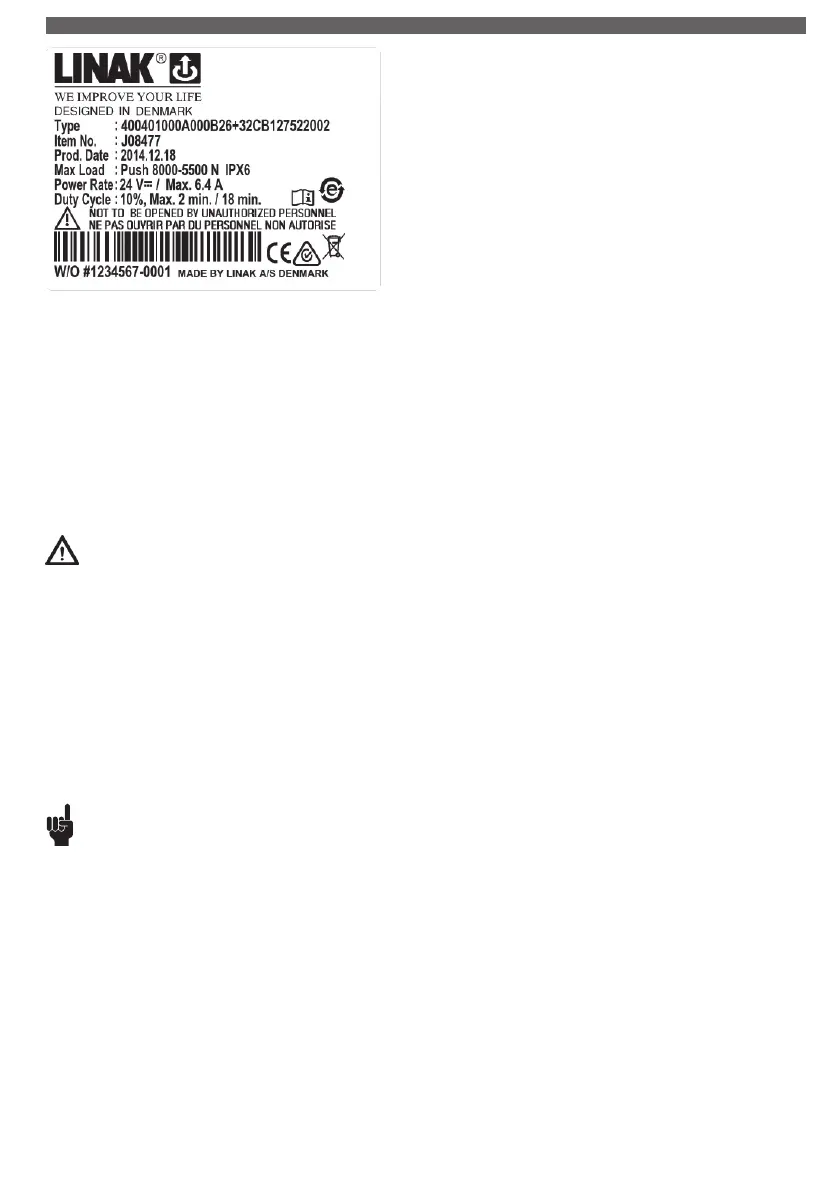

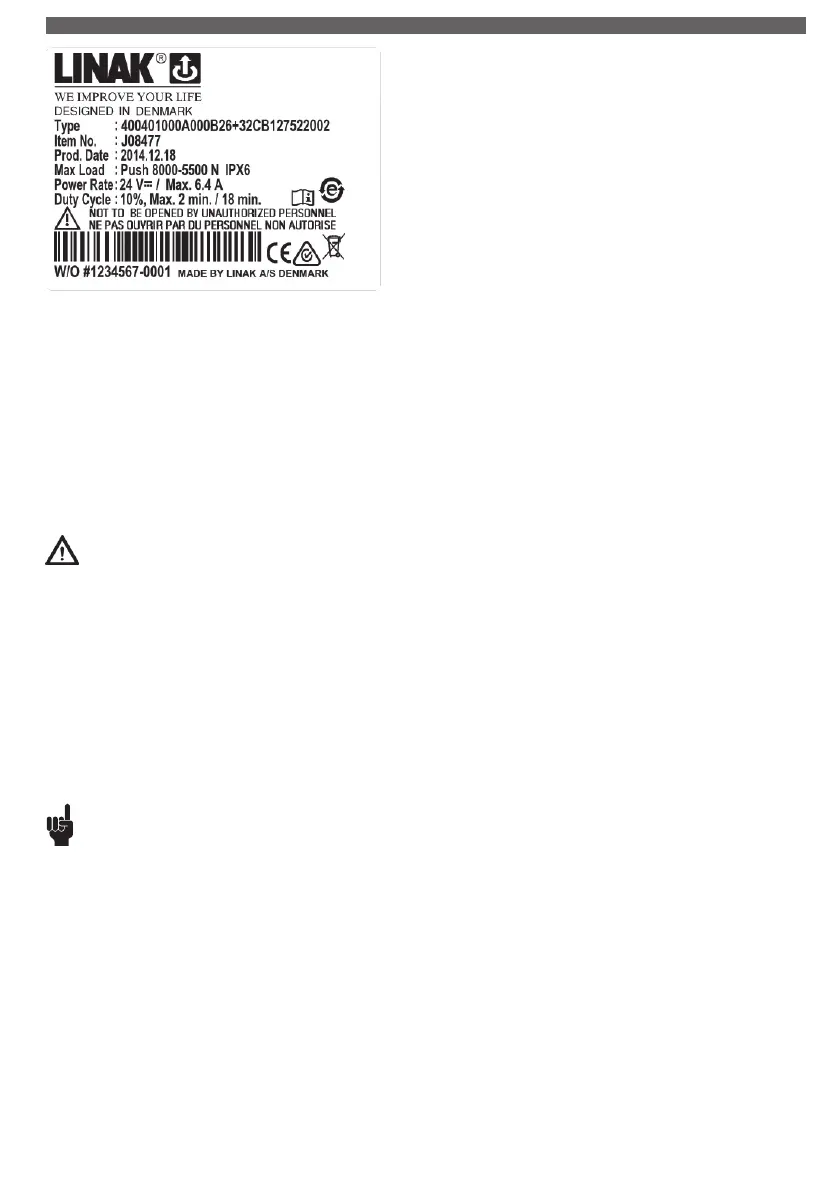

Usage

• Duty cycle: 10 %, 2 minutes continuous use, followed by 18 minutes not in use

• Usage temperature: 5

o

C to 40

o

C

• Storage temperature: -10

o

C to 50

o

C

• Compatibility: Compatible with LINAK control boxes. Please contact LINAK

• Relative humidity: 20% to 80% - non-condensing

• Atmospheric pressure: 700 to 1,060 hPa

• Height above sea level Max. 3,000 meters

• Flammability rating: UL94V-2

• Approvals: IEC 60601-1, ANSI/AAMI ES60601-1, CAN/CSA-C22.2 No 60601-1

Warning

• The installation of spline actuators is recommended by LINAK where possible to avoid the squeezing of body parts.

• The safety option manual lowering makes it possible to turn the inner tube down by hand in emergency cases or if electrical power is not available.

• Activation of a quick release can lead to a risk of squeezing body parts. Installation of a damper may reduce this risk.

• A quick release can accidentally be activated during mounting or maintenance. To avoid this, operators must be warned before service/mounting.

• End of life issue: defective switches - endstop:

If the electrical endstop switch for outward operation fails, it may cause a prolonged actuator stroke and in addition the customer application may

collapse. To avoid this, the manufacturer must take this into account when designing and making a risk analysis.

• If electrical endstop fails to function the actuator will continue to retract or extend until mechanical endstop is reached. The application of the

customer must be able to obtain or withstand an actuator with failing electrical endstop. Minimum length of actuator reaching mechanical endstop:

BID - 7 mm. Maximum length of actuator reaching mechanical endstop: BID + SL + 7 mm.

• If the actuator does not work as intended, there is a risk of injury. Therefore, the actuator must immediately be sent to the nearest authorised LINAK

workshop for service.

• The actuator is not designed for repeated dynamic push-to-pull movement.

Recommendations

• Power supply without current cut-off can cause serious damage to the actuator if a mechanical stop is encountered or the actuator movement is

blocked in another way.

• Connection bolts must be dimensioned so that they have the necessary strength and tolerance in order to obtain the minimum safety factor according

to the requirements of the authorities.

• The actuator must not be subject to a side load, as this can cause bending/collapse of the actuator. The actuator must never be used as a handle.

• The actuator must not be subject to off-centre loading, as this can cause bending/collapse of the actuator.

• The actuator must not be subject to impact, or any form of stress to the casing.

• The actuator must not be subject to overload, as this can reduce the lifetime of the actuator and in the worst case cause damage to the actuator.

• Only use the actuator within the specifications.

• Connection bolts and brackets are to be inspected in connection with service, and must be replaced if there are signs of wear.

• Ensure that the cable lock is mounted correctly.

• Ensure that the duty cycle and the usage temperatures for LA40 actuators are respected.

• Ensure that the cable cannot be squeezed, pulled or subjected to any other stress.

• The LA40 is not suitable for use in outdoor applications where it can be exposed to sun and rain.

• LA40 with mechanical endstop - a first failure safe option:

In many applications customers have approvals in accordance with EN 60601-1. The typical applications are beds, massage couches etc. The norm

EN 60601-1 states that the application must be first failure safe. The manufacturer has the responsibility of carrying out a risk analysis in order to

check this. If a risk is identified, the application manufacturer must ensure that this risk is eliminated. A switch cannot be first failure safe.

The product is not designed for dynamic load changes (from push to pull or vice versa. If the application design requires a product with a dynamic

load change capability, please contact LINAK for investigation of product feasibility or guidance.

Loading...

Loading...