Page 54 of 96

© 2020 LINAK A/S

Only for Non-critical Parallel systems

• The Non-critical Parallel system offers auto-detection for every single power up if a new actuator is added to

the line (system)

• To add or remove actuators from the system, the system needs to be shut down and powered up again.

Please be aware, that after re-powering, the system will not detect if an actuator is missing!

• If adding a new actuator to the system, be aware that the actuator needs to have the same configuration

(Non-critical Parallel) as the existing ones; this can be done via the Buslink software tool

System Monitoring for Parallel

If one of the actuators have one of the following error conditions, the actuator will

immediately STOP:

• H-Bridge fault

• Out of the temperature range (High duty cycle protection)

• Overcurrent (Current cut-off if one or all actuators go in mechanical block)

• SMPS fault

• EOS fault switch

• Hall sensor failure

• Position lost

• Overvoltage (43V DC)

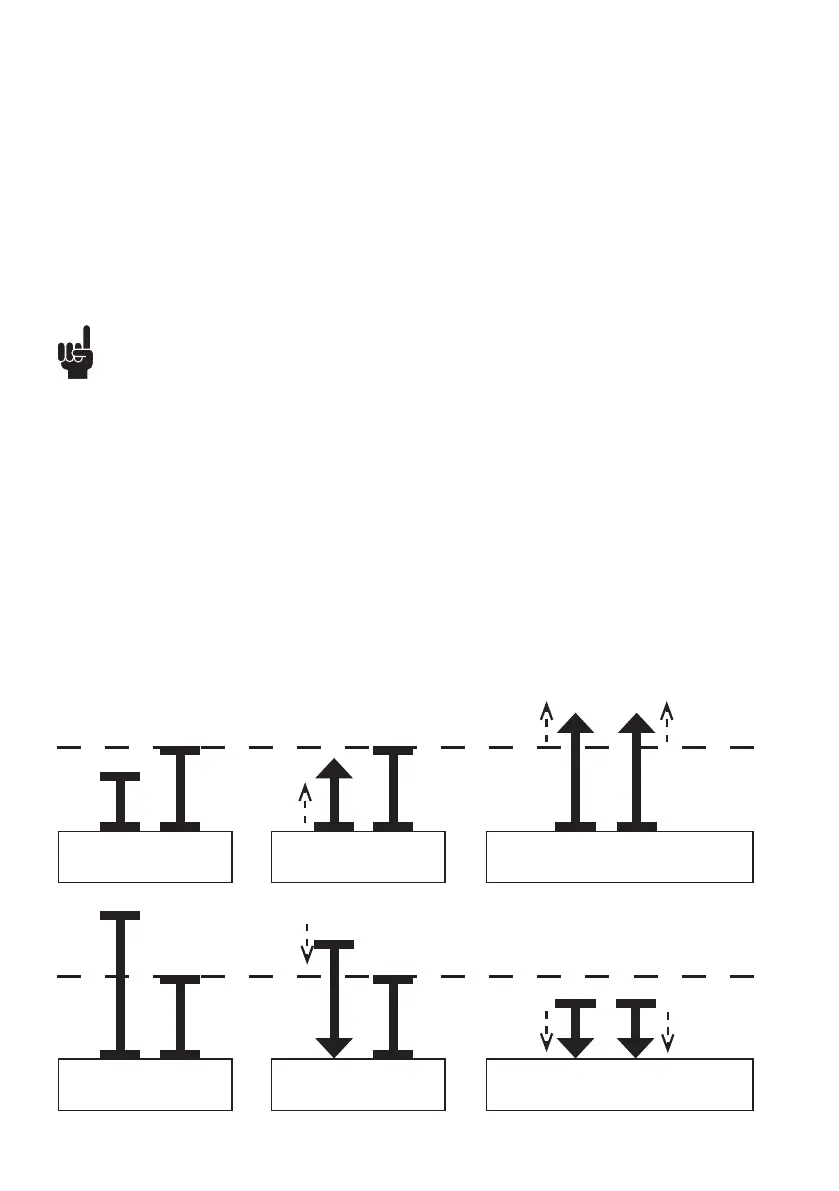

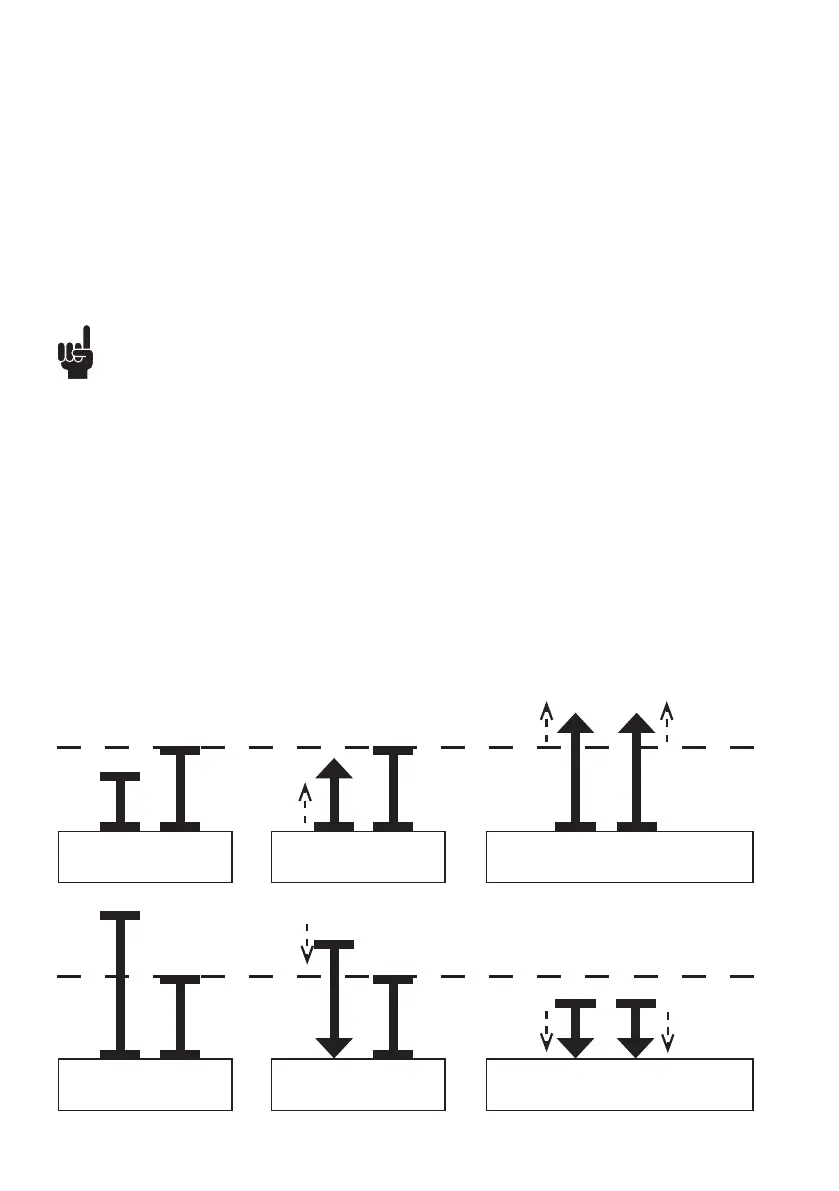

If the actuators are not in parallel when starting up, the next movement will run in the following manner:

Alignment of the parallel actuator system

Start position

Running outwards

When completely aligned, the

parallel run continues outwards

Start position

Running inwards

When completely aligned, the

parallel run continues inwards

Loading...

Loading...