ELECTRIC SYSTEM TMS700E SERVICE MANUAL

3-14 Published 01-29-2015, Control # 512-01

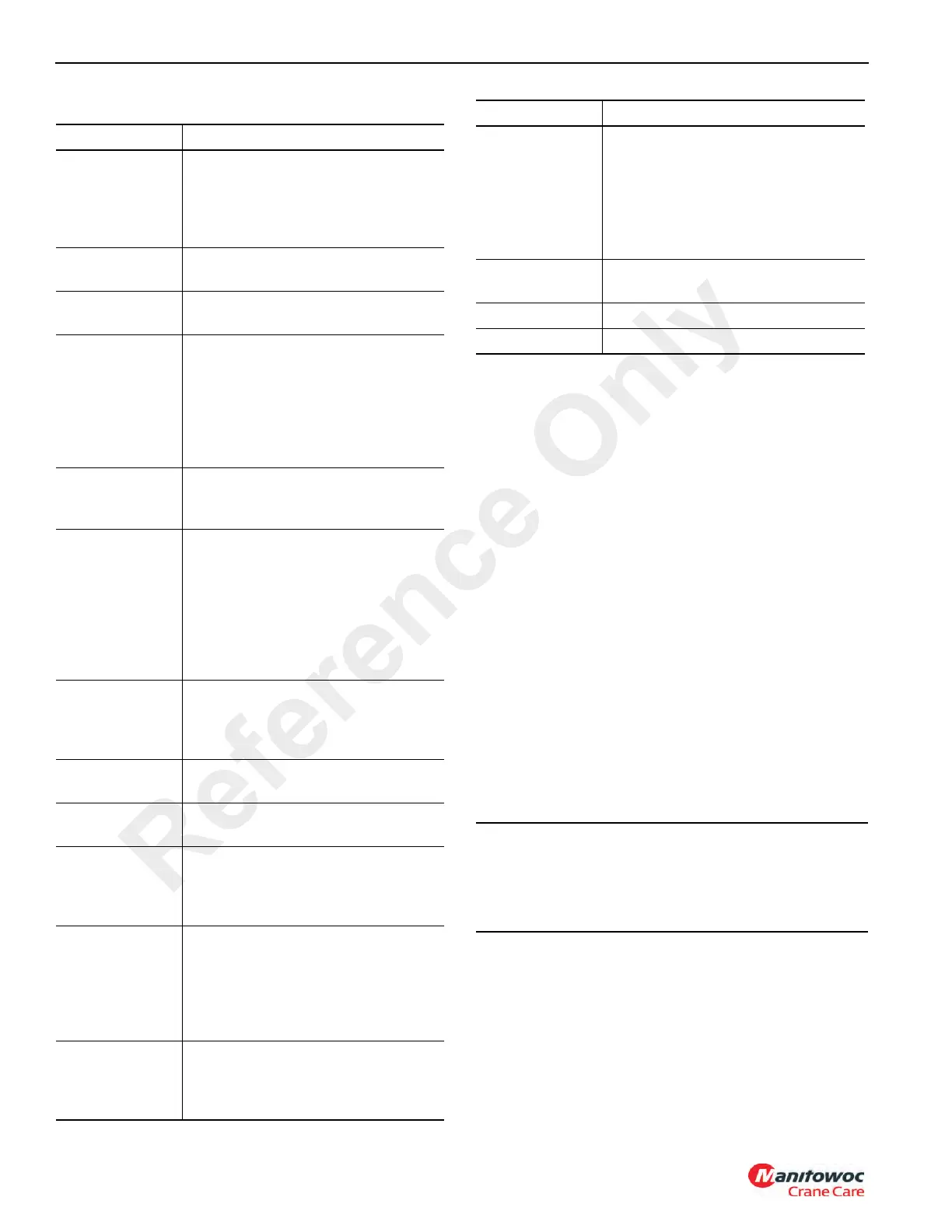

Table 3-15

3. Repair is straightforward.

a. MOTOR: check and/or replace fuse, remove faulty

motor or faulty trigger (switch, relay), install new

motor or trigger, test motor. For further information,

see the applicable section in this manual.

b. SOLENOID VALVE: check and/or replace fuse,

remove faulty valve or solenoid, install new valve or

solenoid, fill fluid system, test valve.

c. RCL: check and/or replace fuse, repair per RCL

manual, test per RCL manual.

d. ROTATION INDICATOR: check and/or replace fuse,

remove driver assembly or sensor, install driver

assembly or sensor, test thumper. For further

information on rotation indicator, see Hoist Drum

Indicator System, page 5-10 or the applicable SM

package.

Alternator Replacement

NOTE: On cranes with air conditioning it may be

necessary to move the compressor to gain access

to the alternator.

Removal

1. Turn the ignition switch off two minutes before

proceeding to the next step.

2. Turn the battery disconnect switch to OFF.

3. Remove the ECM power fuse.

4. Disconnect the batteries starting with the negative

terminals.

5. Open the engine compartment.

Component Circuit

Windshield

Wiper Motor

and Windshield

Washer Pump

Motor

F18, wiper/washer switch, motors in

parallel, grounds

Heater or A/C

Fan

F16, FAN switch, fan motor, ground

Cab Circulating

Fan

F13, switch, motor, ground

A/C Control

Functions

F16 to FAN switch to A/C ON-OFF

switch to fans relay coil to ground.

Parallel circuit to LED indicator in A/C

ON-OFF switch to ground. Parallel

circuit to thermostat contacts to

binary pressure switch contacts to A/

C compressor clutch to ground

A/C Condensor

Fan Motors

Fuse F17 to fans relay contacts to

condensor fan motors in parallel to

ground

Crane Function

F14, crane function switch, seat

switch, left armrest switch, crane

function relay (K5) coil, ground.

Branch in parallel from crane function

switch to crane function relay

contacts to crane function solenoid

valve to ground. Parallel circuit to

LED indicator in switch to ground

Main and

Auxiliary Hoist

Rotation

Indicators

F15, branch for each hoist (driver

assembly, sensor, driver assembly,

ground). Parallel branch through

thumper to driver assembly

RCL

F11, RCL CPU and RCL crane

components, grounds

Lockout

Function

F11, RCL CPU, three or four lockout

solenoid valves in parallel, grounds

Swing Brake

Release

Function

F10, swing brake release switch,

swing brake release solenoid valve,

ground. Parallel circuit to LED

indicator in switch to ground

Hydraulic Boost

Function

From upstream of crane function

relay contact (see crane function

circuit) to hydraulic boost switch to

hydraulic boost solenoid to ground.

Parallel circuit to LED indicator in

switch to ground

Main Hoist High

Speed Function

F12 to main hoist high speed switch

to hoist speed solenoid valve on hoist

to ground. Parallel circuit to LED

indicator in switch to ground

Auxiliary Hoist

On/Off function

For hoist up, F11 to RCL CPU to aux

hoist switch to auxiliary hoist up

solenoid valve to ground. For hoist

down, CB12 to aux hoist switch to

auxiliary hoist down solenoid valve to

ground. Parallel circuit to LED

indicator in switch to ground

Skylight Wiper

Motor

F13, wiper switch (on motor), motor,

grounds

Beacon Light F18 to beacon light to ground

Switch LED’s F18 to seven parallel LED’s to ground

CAUTION

To prevent damage to electronics, in order: Ensure

keyswitch has been off 2 minutes, Battery disconnect is in

the off position, Remove ECM power fuse, Remove

negative cables, Remove positive cables (if required).

Component Circuit

Reference Only

Loading...

Loading...