ELECTRIC SYSTEM TMS700E SERVICE MANUAL

3-12 Published 01-29-2015, Control # 512-01

3. Repair is straightforward.

a. For a gauge or meter, check or replace fuse,

remove gauge or meter, install new gauge or meter,

then test gauge or meter.

b. For a sender, check or replace fuse, remove sender,

install new sender, then test sender and gauge or

meter. See Instrument Replacement, page 3-17 in

this section for details on removing and installing

gauges and meters.

Troubleshooting Alarms, Indicators, and

Emergency Components

1. If an indicator won’t work when it is supposed to, check

its lamp first. Replace any damaged lamp. Then check

and replace fuse as applicable, especially if all other

components downstream from the fuse are not working.

Also, check and replace its relay as applicable.

2. If an alarm or an emergency component won’t work

when it is supposed to, check and replace its fuse,

especially when all other components downstream from

the fuse are not working. Also, check and replace its

relay as applicable.

3. Check the alarm or indicator or emergency component,

its sensing component, and circuit for continuity

problems and other problems. Repair any faulty alarm or

indicator or emergency component or sensing device

(switch, relay, sending unit). Repair wiring if faulty.

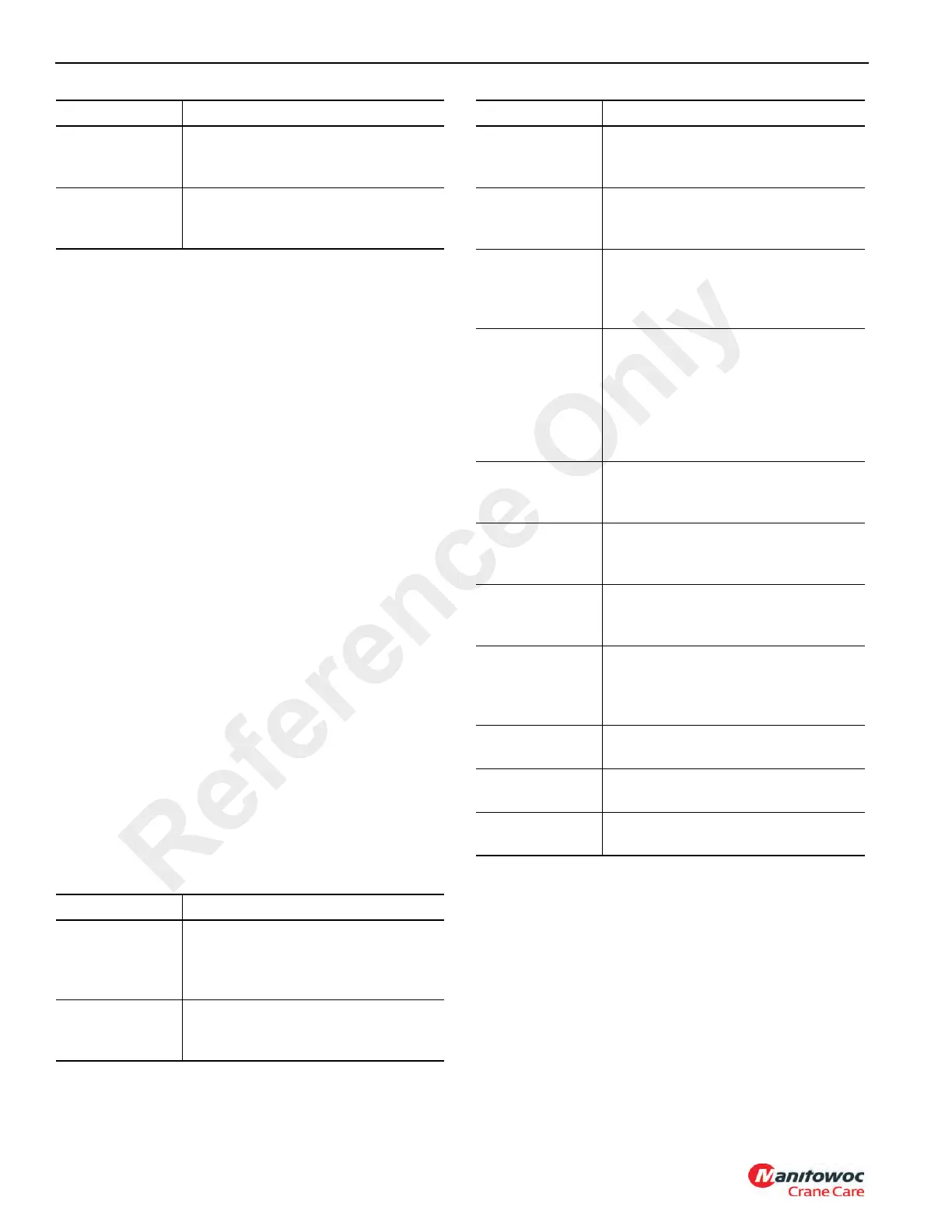

The following carrier circuit designs apply (Table 3-12)

(connecting wiring and passage through swivel slip ring -- as

applicable -- is understood):

Table 3-12

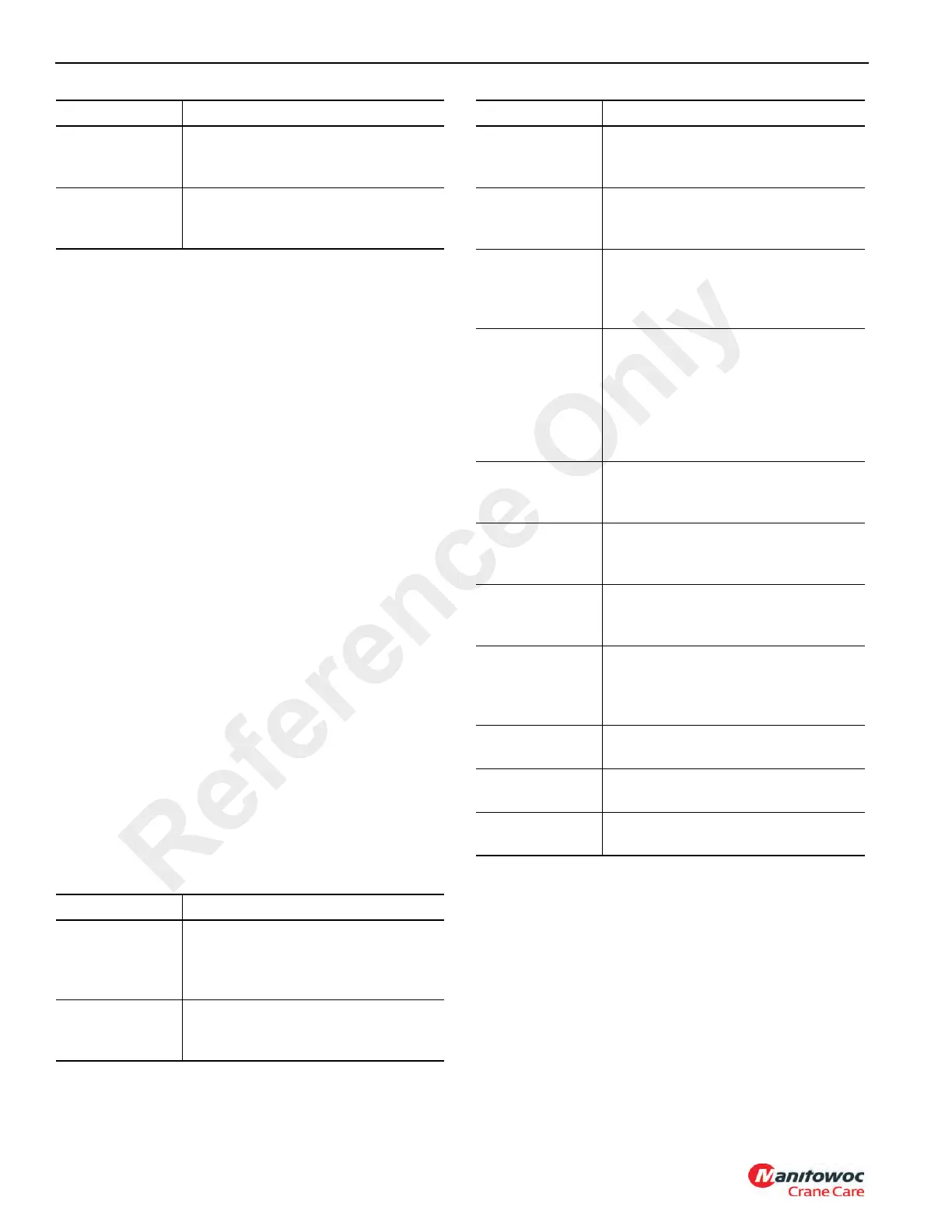

The following superstructure circuit designs apply (Table 3-

13) (connecting wiring and passage through swivel slip ring -

- as applicable -- is understood):

Tachometer

F5/F9, tachometer. Meter is

grounded. Branch from tachometer to

tachometer sender to ground

Speedometer

F5, gauge. Gauge is grounded.

Branch from speedometer to engine

ECM and back to speedometer

Component Circuit

Backup Light

and Backup

Alarm

F15, backup switch, relay K108, then

to backup light in parallel with backup

alarm; then from light and alarm to

grounds

Park Brake

Indicator

F5, indicator, normally closed park

brake pressure switch on cab front

console control valve, ground

Gauge/Meter Circuit

Steering Wheel

Horn

F6, horn relay K106 coil, horn switch,

ground. Parallel branch from horn

relay contacts, horn, ground

Low Air

Pressure

Indicator

F5, to indicator or buzzer to two

parallel normally closed pressure

switches on the dual brake valve

Tire Inflation On

Indicator

F5, to indicator or buzzer to the

normally open pressure switch on the

cab front console control valve to

ground.

Swing Brake On

Indicator

F5, to indicator or buzzer to the

normally open pressure switch on the

cab front console mounted trailer

brake control valve to normally open

pressure switch on the trailing boom

swing valve on the superstructure to

ground

Hydraulic Pump

Engaged

Indicator

F5 to indicator to switch on pump

disconnect lever to ground

Cross Axle

Differential Lock

On Indicator

F5 to indicator to switch on axle to

ground

Inter-Axle

Differential Lock

On Indicator

F5 to indicator to normally open

pressure switch on cab front console

control valve to ground

Suspension

Deflated

Indicator

F5 to indicator to four (one at each air

bag suspension) normally closed

pressure switches connected in

series to ground

Engine Stop

Indicator

F5 to indicator or buzzer to engine

ECM

Engine Warning

Indicator

F5 to indicator to engine ECM

Engine Service

Indicator

F5 to indicator to engine ECM

Component Circuit

Reference Only

Loading...

Loading...