HYDRAULIC SYSTEM TMS700E SERVICE MANUAL

2-70 Published 01-29-2015, Control # 512-01

Assembly

NOTE: Lubricate seals and rings with clean hydraulic oil.

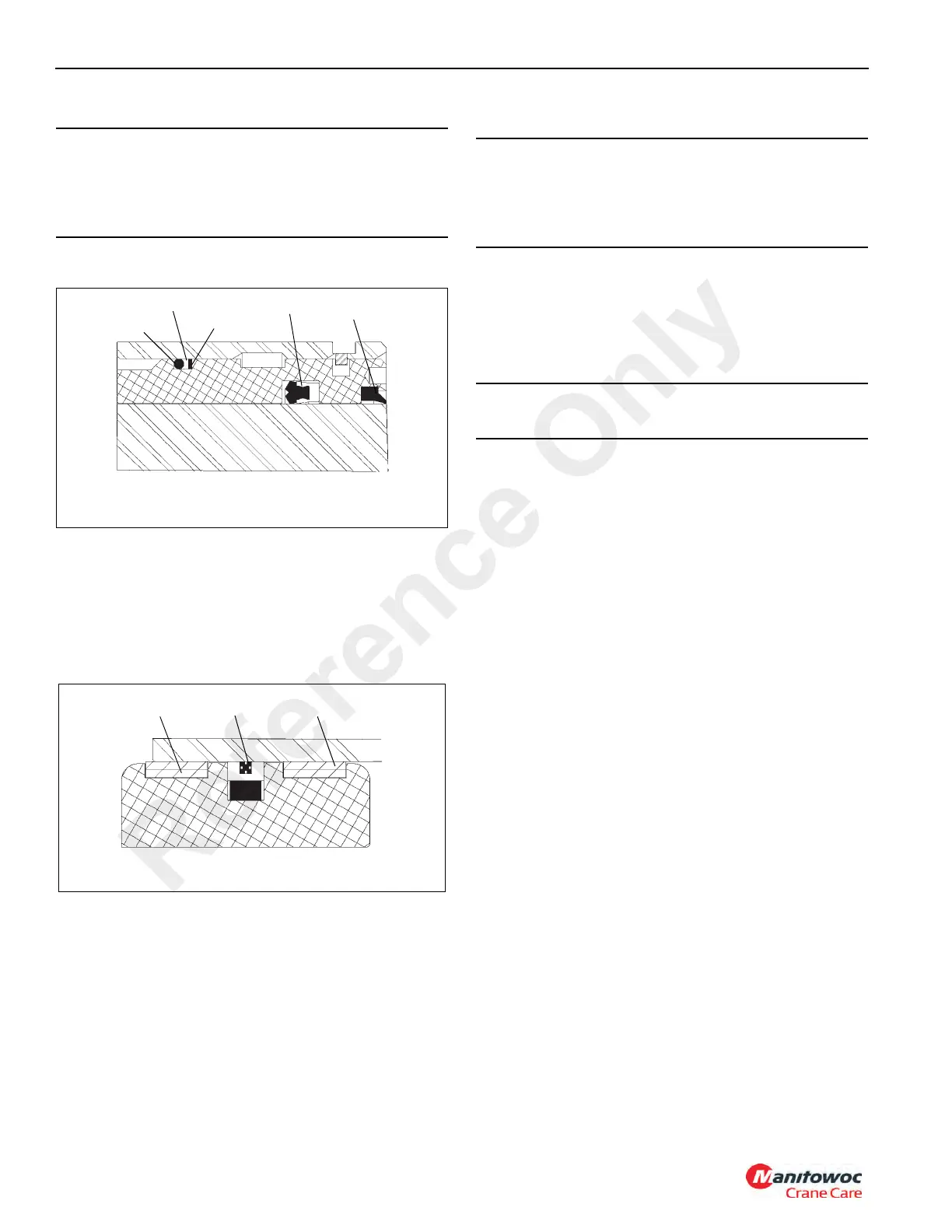

1. Install the replacement seal and wiper ring in the inside

of the head (Figure 2-53).

2. Install the replacement O-ring, backup ring and retaining

ring on the outside of the head (Figure 2-53).

3. Lubricate the rod with clean hydraulic oil.

4. Slide the head, retaining ring end first, onto the rod.

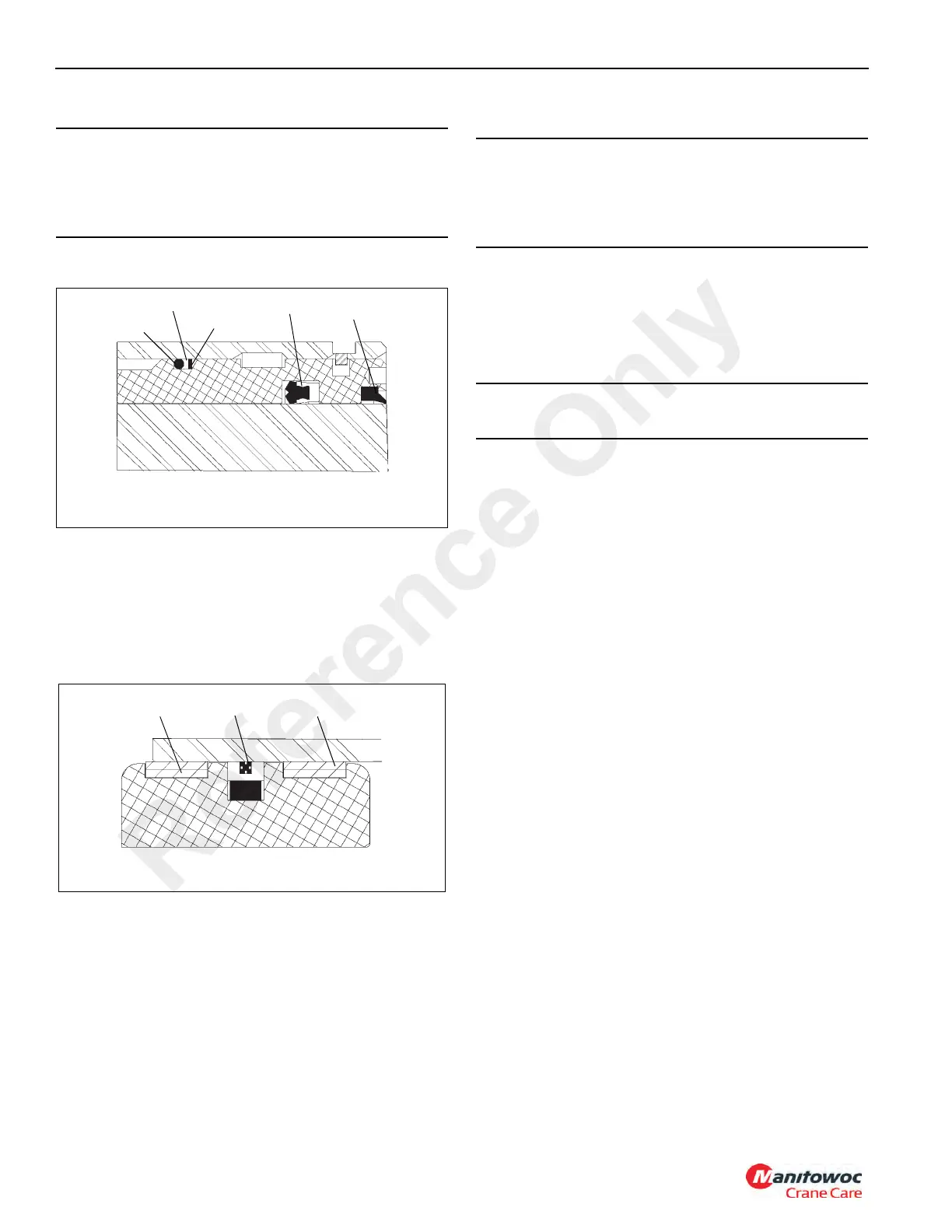

5. Install the replacement wear rings and seal on the

outside of the piston (Figure 2-54), and the O-ring on the

inside of the piston.

6. Install the piston on the rod and secure with the locknut.

7. Lubricate all parts freely with clean hydraulic oil.

8. Remove the cover from the barrel. Insert the rod and

attached parts into the barrel with a slight twisting

motion.

9. Push the head into the barrel. Use a spanner wrench

and tighten the head.

10. Pressurize and cycle the cylinder with hydraulic oil

pressure. Test the cylinder at 207 bar (3000 psi). Check

for proper operation and any leakage. Make repairs as

needed.

OUTRIGGER JACK CYLINDER

Description

The four outrigger jack cylinders (Figure 2-55) each have a

hollow rod for internal porting. Each cylinder has a 11.4 cm

(4.5 in) diameter bore. A port block is welded to the rod of

each cylinder and a pilot operated check valve is threaded

into each port block. The retracted length of the cylinder from

the end of the barrel to the center of the rod’s port block rod

bushing is 112.06 ± 0.030 cm (44.12 ± 0.12 in). The

extended length of the cylinder from the end of the barrel to

the center of the rod’s port block rod bushing is 165.4 ± 0.030

cm (65.12 ± 0.12 in). Its stroke is 53.34 cm (21.0 in). A wiper

ring prevents foreign material from entering the cylinder. O-

rings and other seals prevent internal and external leakage.

The cylinder weighs approximately 63.30 kg (139.5 lb).

Maintenance

Disassembly

NOTE: Any maintenance requiring disassembly of the

cylinders should include replacement of all seals

and rings. A seal kit will supply the required items.

CAUTION

When installing new seals and rings, avoid stretching

seals or scratching the grooved or gland surfaces. Make

sure parts are clean before and during assembly. Make

sure seals and rings are installed in the proper order.

FIGURE 2-53

O-ring

Backup Ring

Retaining RIng

Seal

Wiper Ring

6296

FIGURE 2-54

Wear Ring

Wear Ring

Seal

6295

CAUTION

Exercise extreme care when handling the rod. Damage to

the rod surface may cause unnecessary maintenance

and expense. Also, take care to avoid damaging grooved

or gland surfaces or rings or seals during rod insertion.

CAUTION

Do not use air pressure to cycle or pressurize the cylinder.

Reference Only

Loading...

Loading...