UNDERCARRIAGE TMS700E SERVICE MANUAL

8-24 Published 01-29-2015, Control # 512-01

Maintenance

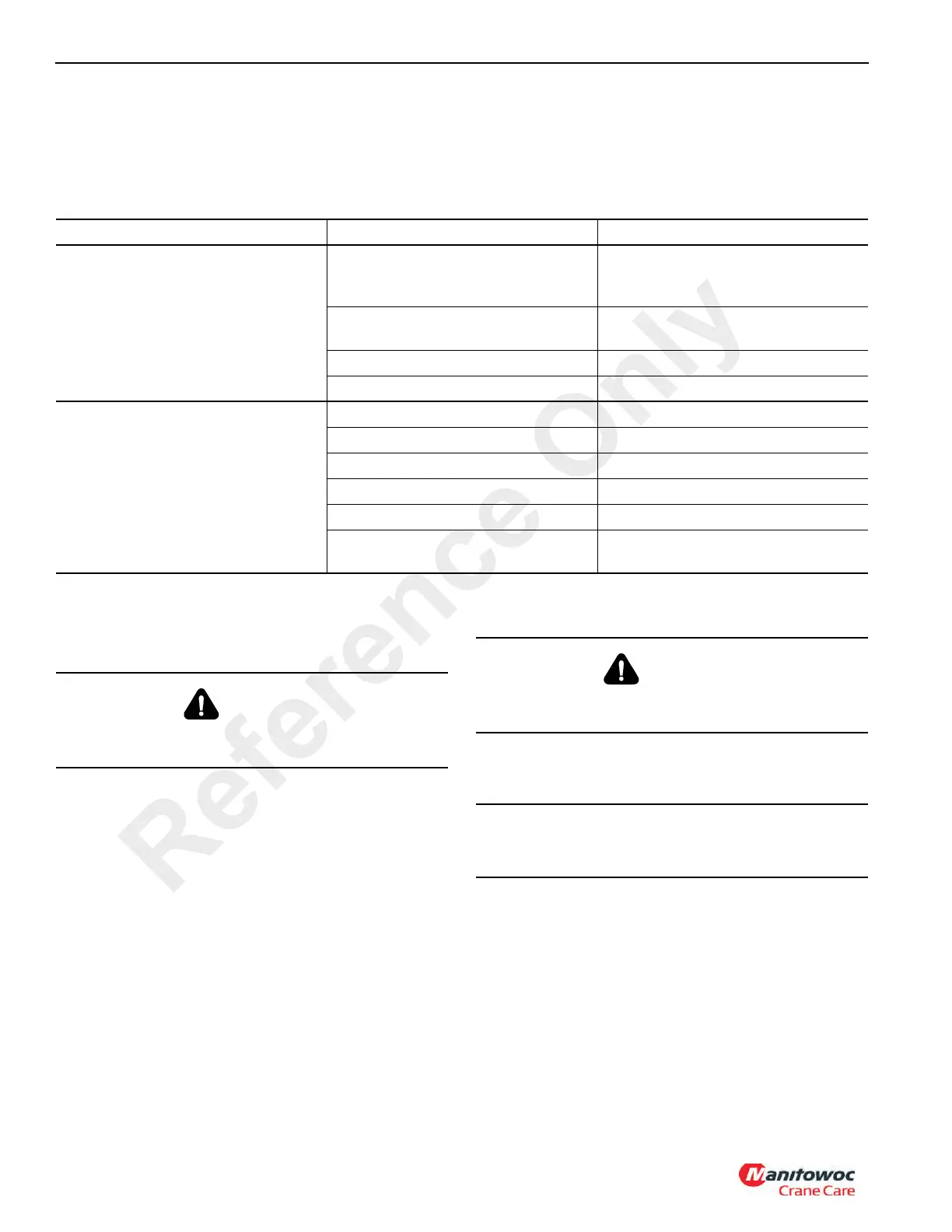

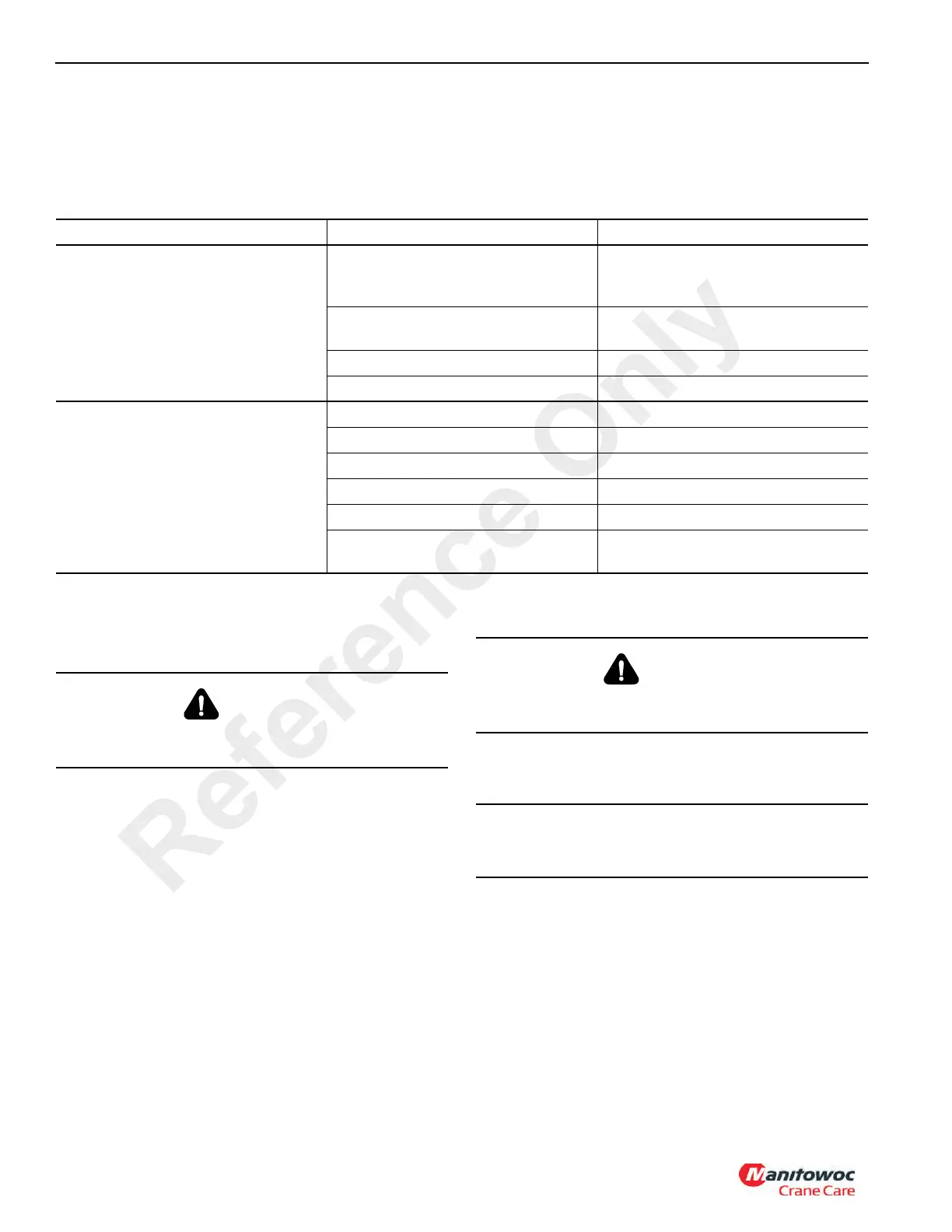

Table 8-2

Troubleshooting

Brakes

Disassembly

1. Set the parking brakes and block the wheels.

2. Raise the carrier so that the front wheels are off the

ground.

3. Install jack stands under the carrier.

4. Back off the automatic slack adjuster until the brake

shoes are clear of the drum.

5. Remove the hub cap, axle spindle nut, and washer.

6. Rock the drum and pull outward until the outer wheel

bearing can be removed.

7. To remove the drum, pull outboard while rocking from

side to side.

Symptom Probable Cause Solution

1. Brakes are poor or do not apply. a. Insufficient air pressure. a. Check for the correct pressure

at the compressor and brake

air chambers.

b. Restriction or leak in lines,

valves, etc.

b. Check all lines, valves, etc.,

for leaks or restrictions.

c. Brakes out of adjustment. c. Adjust the brakes.

d. Leaking diaphragm. d. Replace the diaphragm.

2. Uneven braking or uneven lining

wear.

a. Ruptured diaphragm. a. Replace the Diaphragm.

b. Brakes out of adjustment. b. Adjust the brakes.

c. Grease on the lining. c. Replace the lining.

d. Glazed lining. d. Replace the lining.

e. Shoes installed backwards. e. Reverse the shoes.

f. Combination linings. f. Remove the linings and

replace with the correct style.

DANGER

Do not work under a crane supported by only outrigger

jacks. Use jack stands to support the carrier.

DANGER

Do not strike the axle shaft flange with a hammer. Do not

use chisels or wedges to loosen shaft or dowels.

CAUTION

Do not force the drum. Excessive force may damage

brake components.

Reference Only

Loading...

Loading...