Grove Published 01-29-2015, Control # 512-01 8-51

TMS700E SERVICE MANUAL UNDERCARRIAGE

a. The Air Pressure Low Light and warning buzzer will

come on when the secondary air pressure drops

below 5.17 ± 0.34 bar (75 ± 5 psi).

b. The pressure in the secondary circuit should not

drop below 5.90 ±0.34 bar (85 ±5 psi).

c. Depressurize the secondary system to zero.

16. Check that all the wheels can be rotated.

17. Apply the service brakes.

a. The rear front axle and the rear axles’ service

brakes should be applied and the brake lights on the

rear of the carrier should be on.

b. Release the service brakes and check that all

wheels turn freely.

c. Close the drain valves and recharge the system.

18. Apply the parking brakes.

19. Lower the crane to the ground off the outriggers.

20. With the engine running, position the Suspension

Control Valve Lever to the INFLATE position to inflate

the air suspension bags. The Amber Deflate Indicator

light should go out when the pressure in the air bags

goes above 0.28 ± 0.14 bar (4 ± 2 psi).

21. Continue charging the system until the air dryer cycles

and the compressor shuts off. All system gauges should

read 9.30 bar (135 psi).

22. Check that all suspension air bags are properly inflated.

The top surface of each air bag saddle should be parallel

with the bottom horizontal surface of the carrier frame.

AIR SYSTEM COMPONENTS

Description

Air Compressor

The air compressor is mounted on and driven by the engine.

It provides the source of compressed air for the operation of

the air system components. It is controlled (cycled on and

off) by an air governor. The compressor has a capacity of

0.53 cm/m (18.7 cf/m).

Air Governor

The air governor is mounted on the left side of the air dryer.

The governor senses the system pressure and when

pressure reaches 9.30 bar (135 psi) the governor vents the

compressor. When pressure drops to 7.90 bar (115 psi), the

governor signals the compressor to start charging again.

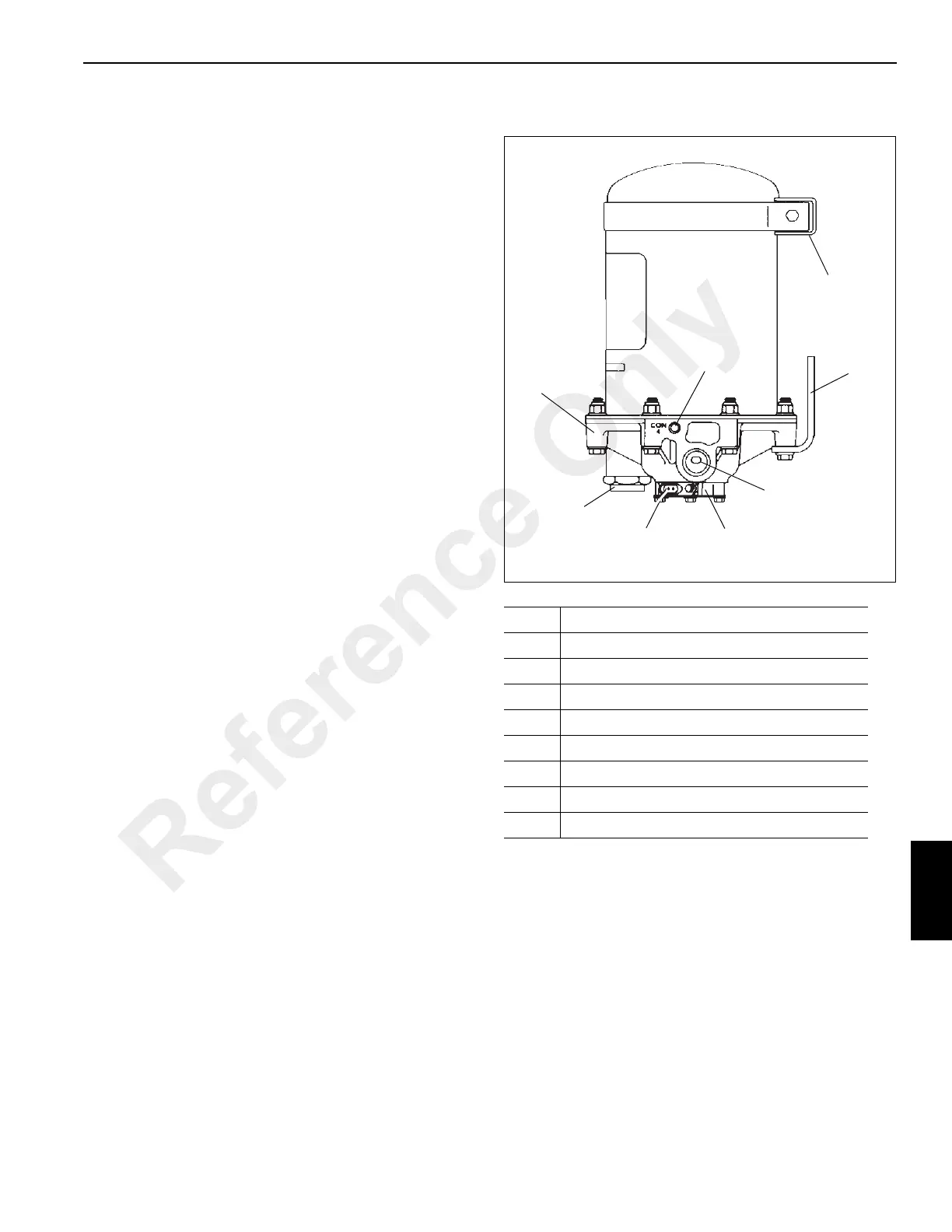

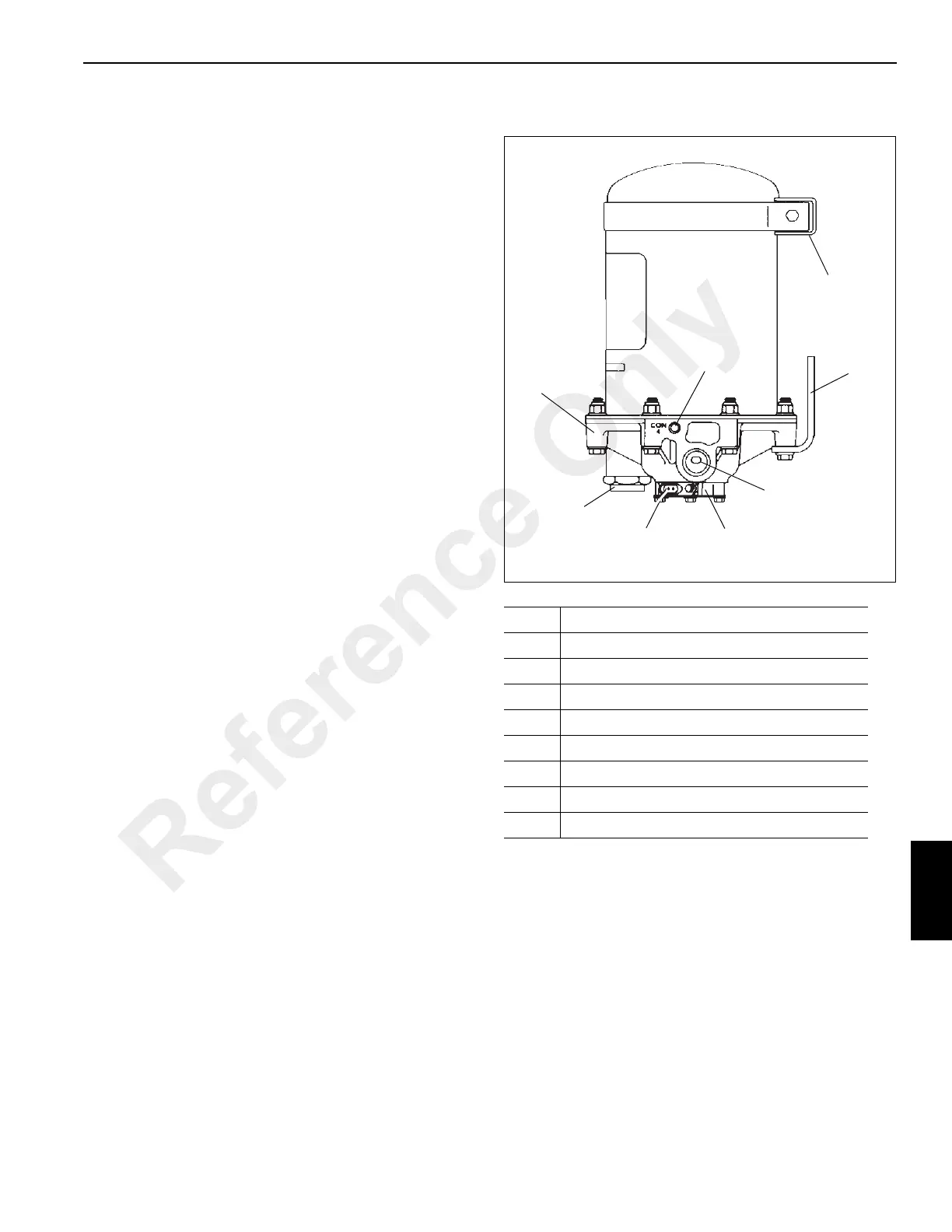

Air Dryer

The purpose of the air dryer (see Figure 8-40) is to collect

and remove solid, liquid, and vapor contaminates from the

air system. Clean dry air increases the life of the air system

and reduces cost.

The dryer consists of a desiccant cartridge and die cast

aluminum end cover secured to a cylindrical steel shell. The

end cover contains a check valve, safety valve, three

threaded connections and purge valve housing. The purge

valve housing contains the purge valve and turbo charger

cutoff. The turbo charger cutoff prevents loss of engine

“turbo” boost pressure during the purge cycle of the air dryer

Item Description

1 End Cover

2 Control Port

3 Upper Bracket

4 Lower Bracket

5 Delivery Port

6 Female Connector

7 Purge Valve Housing

8 Supply Port

Reference Only

Loading...

Loading...