UNDERCARRIAGE TMS700E SERVICE MANUAL

8-70 Published 01-29-2015, Control # 512-01

plate, and for proper tracking during beam

extension and retraction.

2. Position the extension cylinder so the hydraulic ports on

the rod end of the cylinder can be accessed. Connect

the hydraulic hoses to the ports as tagged during

removal.

3. Push the cylinder into the outrigger beam. Align the

cylinder rod with the clevis in the beam. Apply anti-seeze

to the clevis pin and secure in place with the clevis pin

and cotter pin.

4. Install the outrigger beam. (Refer to Outrigger Beam -

Installation in this Section).

Functional Check

1. Activate the hydraulic system; extend and retract the

outrigger.

2. Observe the operation of the outrigger beam.

3. Check the hydraulic connections for any evidence of

leakage.

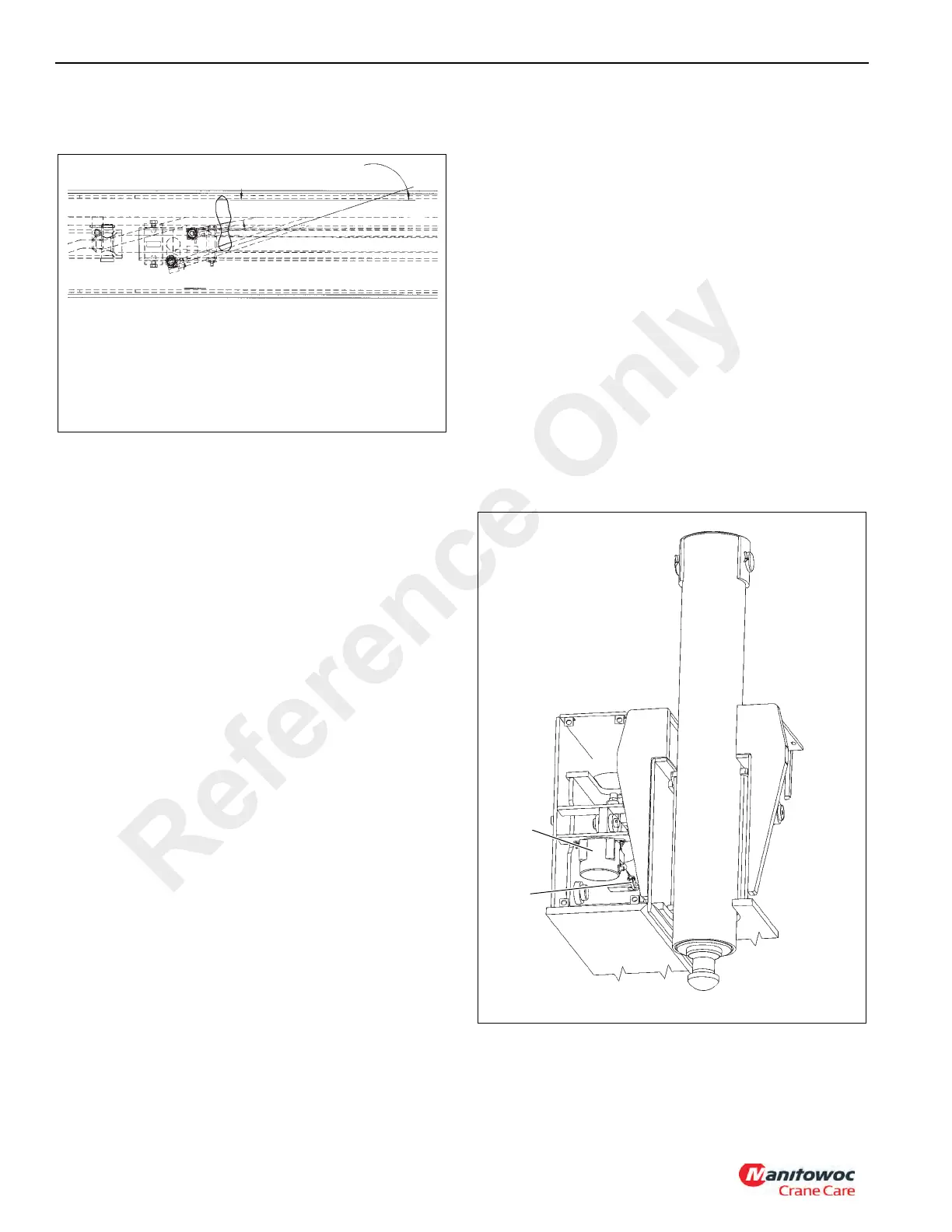

OUTRIGGER MONITORING SYSTEM

(OPTIONAL—STANDARD IN NORTH

AMERICA)

Description

The Outrigger Monitoring System (OMS) aids the operator in

accurately programming the Rated Capacity Limiter (RCL)

by automatically identifying the horizontal position of each

outrigger beam. The OMS uses four sensors, one per

outrigger beam, to identify when an outrigger beam is

positioned to one of three pre-defined locations, including

fully retracted, mid-extend, and fully extended.

Removal

1. Extend the outrigger beam slightly for improved access

and shut down the engine.

2. Remove the outer access cover plate from outrigger

box.

3. Remove the OMS string potentiometer (1, Figure 8-68)

connector (2) from the attaching point on the outrigger

beam.

NOTE: Avoid free-release of cable to prevent damage to

OMS string potentiometer.

4. Disconnect electrical harness connector and secure to

avoid damage.

5. Loosen the mounting hardware enough to disengage

OMS string potentiometer from the slotted mounting

hole.

6. Completely remove the other mounting hardware.

7. Remove OMS string potentiometer from inside outrigger

beam.

10°

FIGURE 8-67

NOTE: Keep hydraulic fittings and hoses close to angles

shown & as low as possible to prevent rubbing with

the beam top plate & side plate, and for proper

tracking during beam extension and retraction.

18°

Reference Only

Loading...

Loading...