INTRODUCTION TMS700E SERVICE MANUAL

1-20 Published 01-29-2015, Control # 512-01

that makes this rope special is that the outer strands are not

preformed. It is because of this that the following procedures

for cutting and preparing 35x7 class wire rope must be

followed:

1. The welded ends prepared by the manufacturer are not

to be removed.

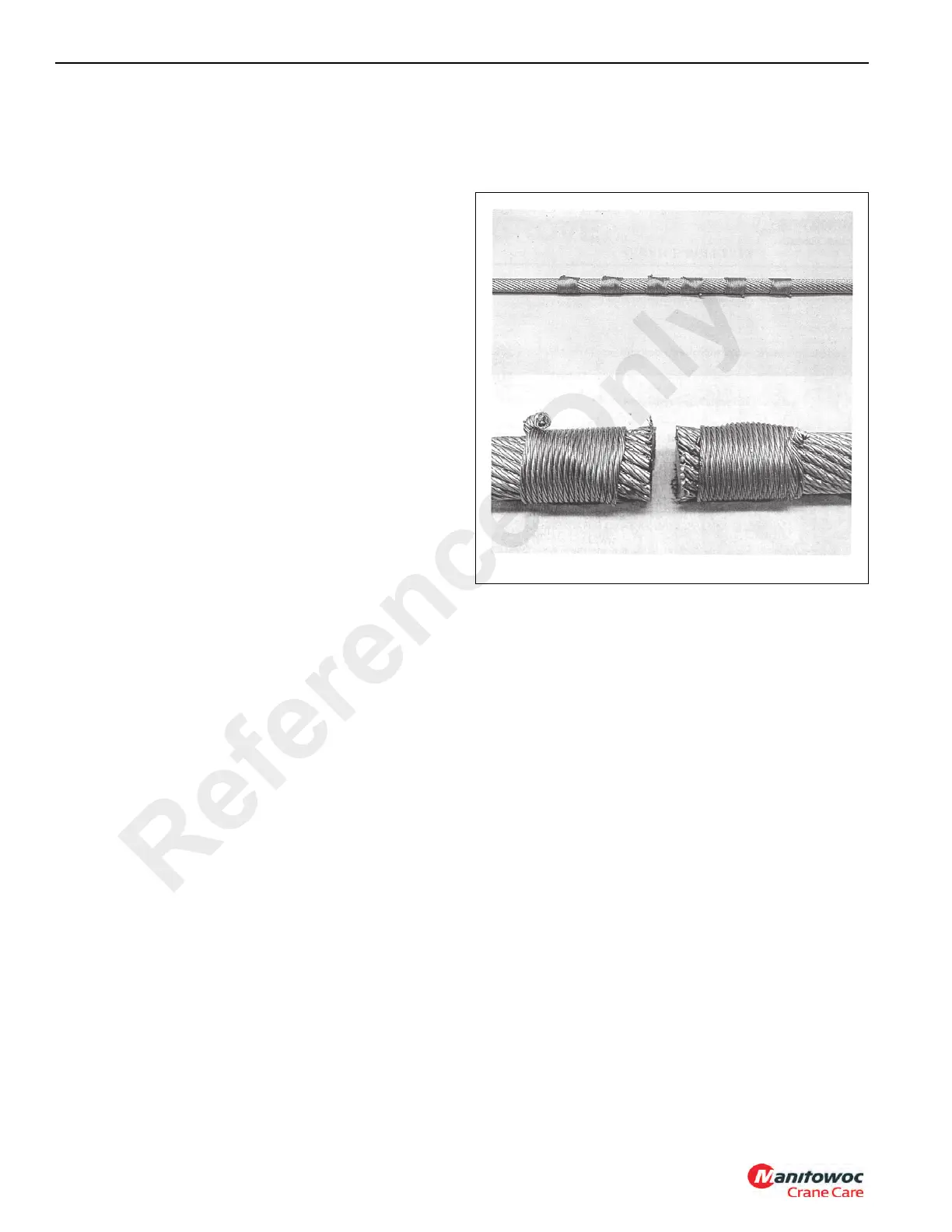

2. Before cutting the rope, make three separate bands with

seizing strand on each side of where the cut is to be

made (total of six bands for each cut). Each band is to

have a minimum length of one and one half times the

rope diameter. The two bands closest to the cut should

be located at a distance equal to one rope diameter

away from the cut. The four remaining bands should be

evenly spaced at a distance equal to three rope

diameters.

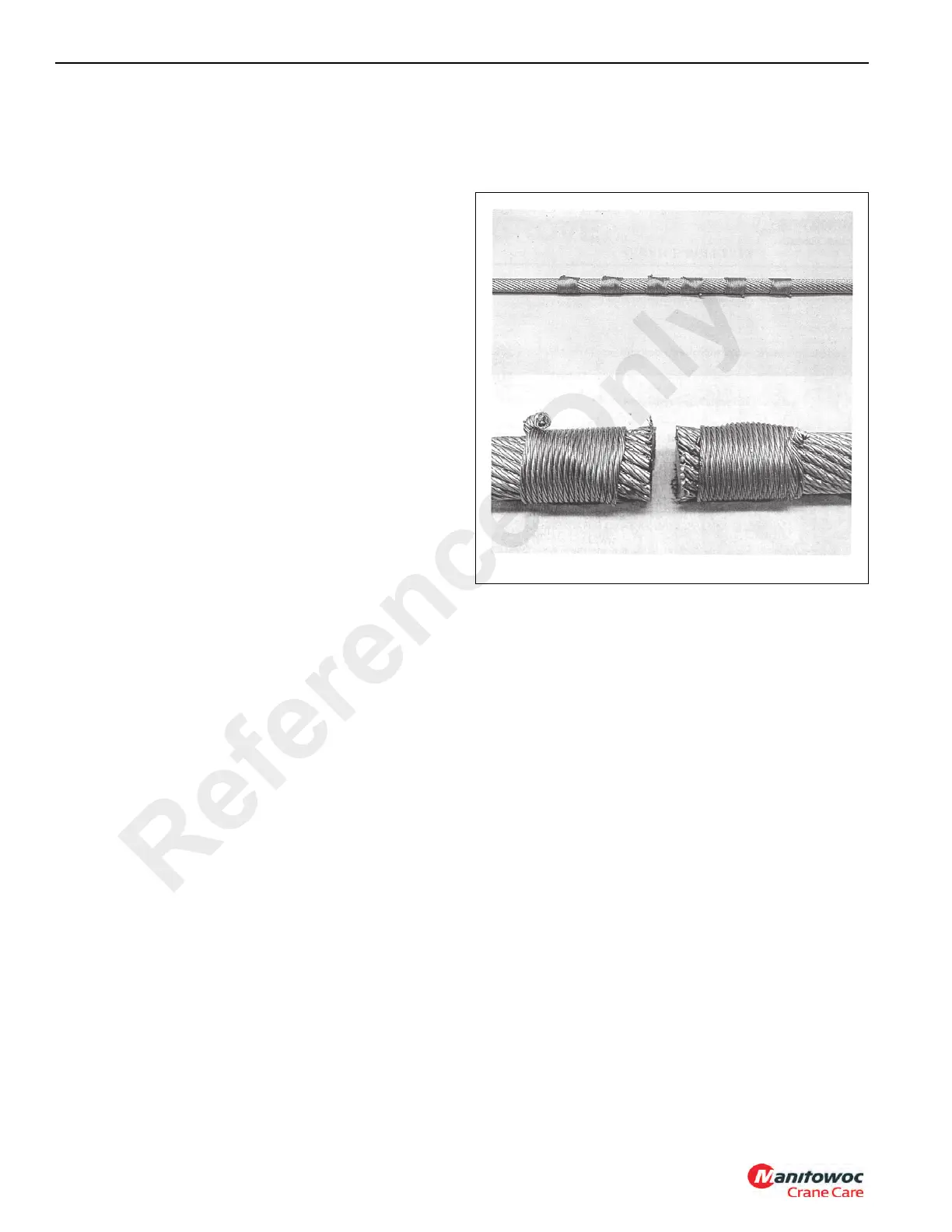

3. Cutting the rope:

a. If a welder is available, the cut should be made with

an abrasive saw. Immediately after the cut, both

ends of the rope are to be cap welded so that all

inner and outer strands are welded together,

preventing any movement between them.

NOTE: The outer strands must not be able to move with

respect to the inner strands. The weld must not

exceed the diameter of the rope.

b. If a welder is not available, the cut is to be made with

an acetylene torch. The cut is to be made in such a

way that both ends of the rope are completely fused

so that all inner and outer strands are bonded

together, preventing any movement between

strands.

NOTE: The outer strands must not be allowed to move

with respect to the inner strands. The fused end

must not exceed the diameter of the rope.

4. Once the cuts have been completed, the seizing bands

are to be left in place for shipment of the rope.

5. Attach a “Do not remove welded ends” tag on each reel

flange.

Synthetic Hoist Rope

For detailed information concerning synthetic hoist rope,

refer to KZ100 Synthetic Crane Hoist Line Manual, P/N

9828100734 available by contacting Manitowoc Crane Care.

Reference Only

Loading...

Loading...