Grove Published 01-29-2015, Control # 512-01 4-13

TMS700E SERVICE MANUAL BOOM

6. Using the lifting device attached to the boom, lower the

boom onto the lift cylinder rod end and extend the lift

cylinder as necessary to align rod with attach fitting on

boom.

7. Lubricate and install the upper lift cylinder shaft. Install a

thrust washer on each side of the lift cylinder rod end.

Secure in place with the stop plate, two bolts, and two

washers.

8. Remove the boom lifting device.

9. Activate the hydraulic system and remove the boom and

lift cylinder blocking devices. Lower the boom to

horizontal. Shut down the crane.

10. Connect the hydraulic lines to the telescope cylinder as

tagged prior to removal.

11. Connect any electrical wires as tagged prior to removal.

12. Refer to Boom Extension and Retraction Cable, page 4-

14 for cable adjustments.

13. Refer to Cam Operated Check Valve Adjustment, page

4-14 for valve adjustment.

Functional Check

1. Activate the hydraulic system and check for proper

operation and any leaks.

2. Ensure the boom will extend and retract properly.

3. Ensure the lift cylinder will not allow the boom to drift

down until the operator lowers it.

4. Ensure all electrical components disconnected during

removal are operating properly.

Inspection

Visually inspect telescoping sections for adequate lubrication

of all wear surfaces. Observe extended sections for

evidence of cracks, warping, or other damage. Periodically

check security of boom wear pads. Check boom nose

sheaves for security and freedom of movement.

Should boom chatter or rubbing noises in the boom occur, it

will be necessary to lubricate the telescope cylinder wear

pads. Refer to Lubrication, page 9-1.

Boom Alignment and Servicing

Refer to Lubrication, page 9-1 for the proper lubricant.

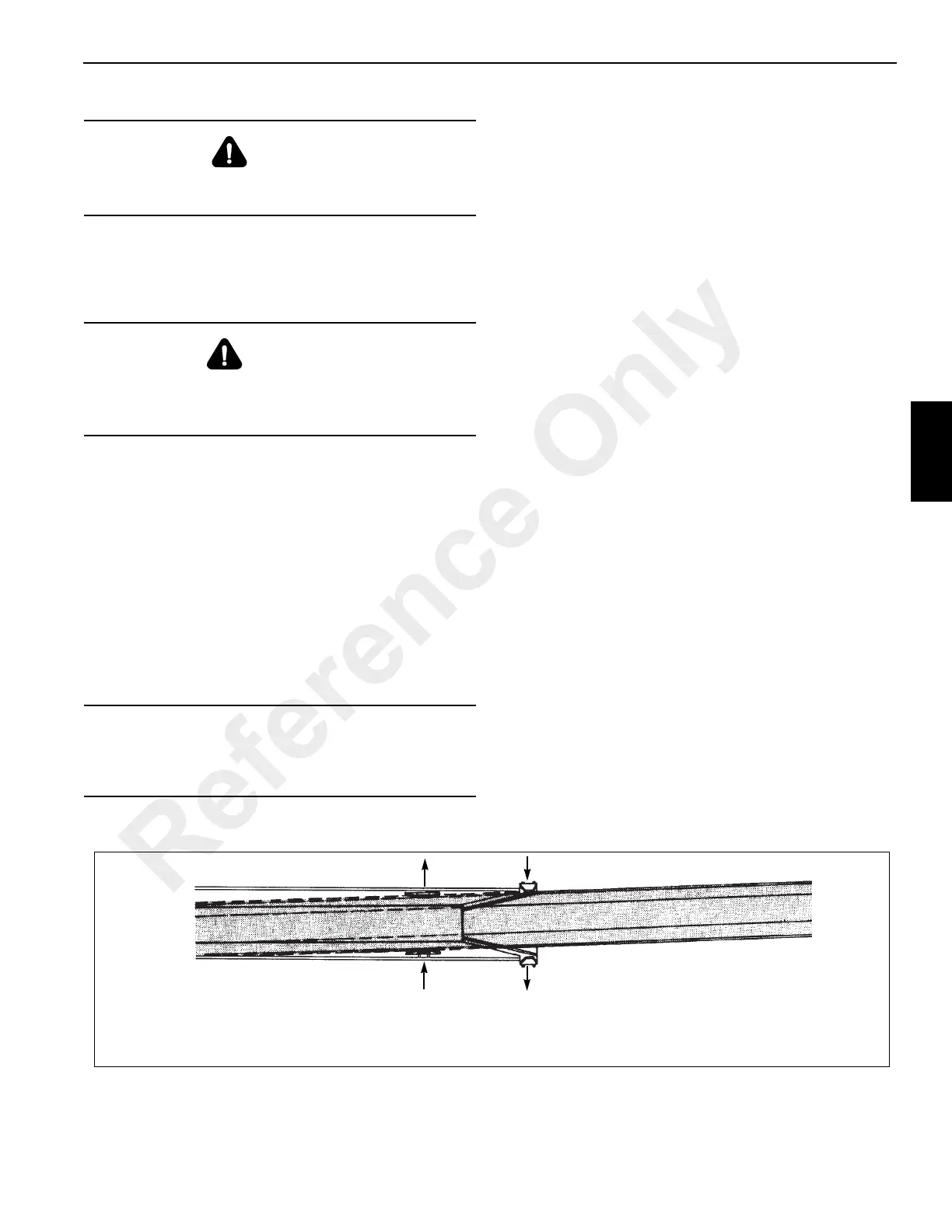

Boom alignment (see Figure 4-2) is achieved by adjustment

of the wear pads located at various points in the boom

assembly. Adjustment of the wear pads is as follows:

1. Fully extend the boom horizontally.

2. Lubricate the boom bottom plates (sides and bottom).

3. Shim the front top wear pads such that wear pad is just

touching or is no more than 2 mm (0.078 in) from

contacting the next section both at the top and side

surfaces of the top radius.

DANGER

Failure to properly support the boom lift cylinder may

result in death or injury to personnel.

WARNING

If the hydraulic system must be activated to extend or

retract the lift cylinder, ensure the rod end is properly

aligned with the lift cylinder attach fitting.

CAUTION

If removed, ensure the large access covers on each side

of the boom Section 1 are installed before extending the

boom.

NOTE: Deflection exaggerated for illustration purposes

FIGURE 4-2

Reference Only

Loading...

Loading...