SWING SYSTEM TMS700E SERVICE MANUAL

6-16 Published 01-29-2015, Control # 512-01

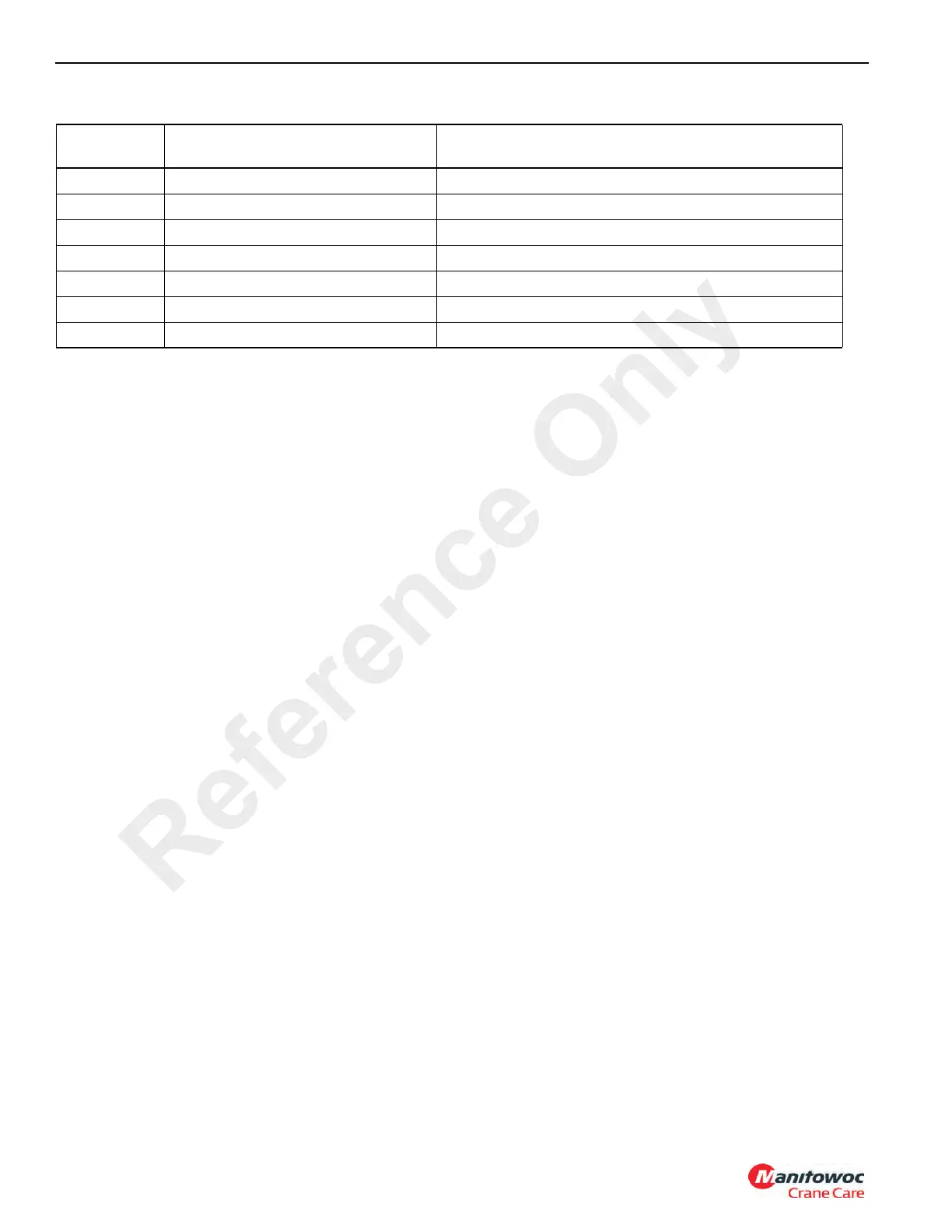

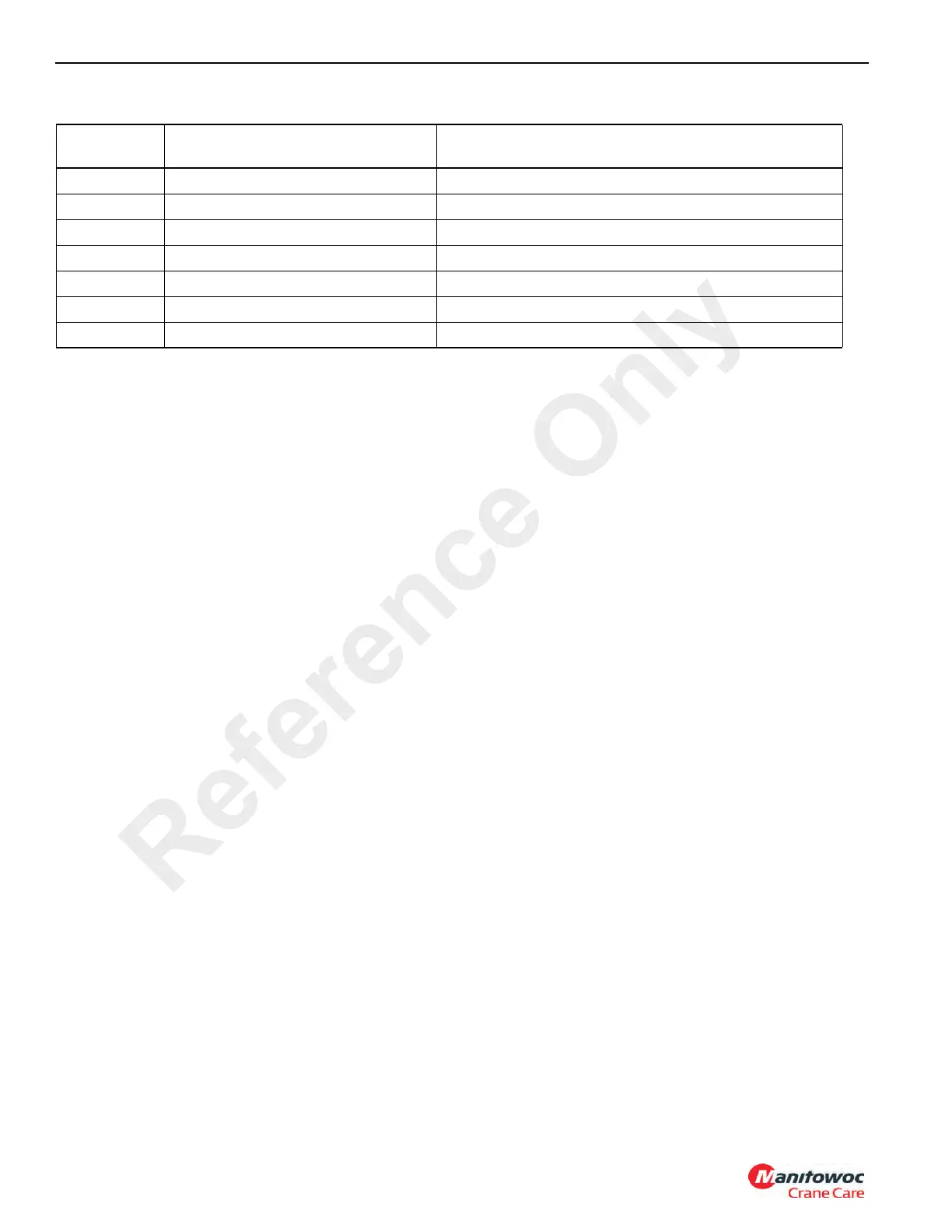

Table 6-1

NOTE: This blocking is to add extra support for the boom.

Any seepage or leakage in the holding valves or

internally in the cylinders will allow the boom to

settle over a period of time.

4. Use the oak blocking to block between the barrel of the

lift cylinder and the boom Section 1.

5. Tag and disconnect the hydraulic lines from the case of

the hydraulic swivel. Cap or plug all lines and openings.

6. Tag and disconnect the hydraulic lines and water lines

from the spool of the hydraulic swivel. Cap or plug all

lines and openings.

7. Tag and disconnect the water lines from the case of the

water swivel. Cap or plug all lines and openings.

8. Disconnect the swivel wiring harness connectors from

the carrier and superstructure receptacles and the

yellow ground wire from the weld stud on the carrier and

superstructure frame. If necessary, remove the electrical

swivel. Refer to Electrical Swivel, page 6-18.

NOTE: The hydraulic swivel weighs approximately 117 kg

(258 lb). The hydraulic, water, and electrical swivel

combined weigh approximately 142 kg (313 lb).

9. On the bottom of the swivel, bend the retainer tabs away

from the bolt heads. Remove the eight bolts and four bolt

retainers securing the two retainer plates to the spool.

Remove the retainer plates from the spool and the lugs

on the carrier frame.

NOTE: It may be necessary to remove some drive line

components to remove the swivel.

10. Position an adequate supporting device beneath the

swivel.

11. Remove the capscrews, washers, and bushings

securing the swivel barrel to the turntable base plate and

lower the swivel to the ground.

Installation

NOTE: The hydraulic swivel weighs approximately 117 kg

(258 lb). The hydraulic, water, and electrical swivel

combined weigh approximately 142 kg (313 lb).

1. Raise the swivel into position.

2. Secure the hydraulic swivel to the turntable base plate

with the bushings, capscrews, and washers. Properly

torque the bolts, refer to Fasteners and Torque Values,

page 1-12.

3. Position the two retainer plates on the hydraulic swivel

spool ensuring they engage the lugs on the carrier

frame. Secure the retainer plates with eight bolts and

four bolt retainers. Apply Loctite 271 to the bolt threads.

Refer to Fasteners and Torque Values, page 1-12 for the

torque value for the eight retainer plate bolts. Bend all

the retainer tabs to make contact with the bolt heads.

Tighten the four retainer plate capscrews, leaving a

maximum 0.79 mm (1/32 in) gap between each bolt and

lug on carrier frame, then tighten the locking nuts.

4. If removed, install the electrical swivel. Refer to

Electrical Swivel, page 6-18. Connect the swivel wiring

harness connectors to the carrier and superstructure

receptacles and the yellow ground wire to the weld stud

on the carrier and superstructure frame. Secure ground

wire with washer, lockwasher and nut.

5. Install the clamp, lockwasher, flat washer and hex head

bolt to the bottom of the swivel retainer plate securing

the wiring harness.

6. Connect the hydraulic lines and water lines to the spool

of the hydraulic swivel as tagged during removal.

7. Connect the hydraulic lines to the hydraulic swivel case

as tagged during removal.

8. Connect the water lines to the water swivel case as

tagged during removal.

9. Remove the blocking material from the lift cylinder.

10. Activate all systems; cycle all functions and observe for

proper operation and any leakage.

Port #

Test Pressure

bar (psi)

Function

1 170 (2500) Air Conditioning

2 34 (500) Dual Return

3 240 (3500) Swing

4 240 (3500) Lift/Tele/Hoist

5 34 (500) Drain

A 2.1 (30) Heater Supply (Coolant)

B 2.1 (30) Heater Return (Coolant)

Reference Only

Loading...

Loading...