Grove Published 01-29-2015, Control # 512-01 8-39

TMS700E SERVICE MANUAL UNDERCARRIAGE

Spring Brake Actuator

The upper part of the brake air chamber containing the large

spring is not serviceable; however, the lower part of the

assembly is serviceable.

1. Remove the caging bolt and washer from its storage

hole on the outside of the brake chamber.

2. Remove the dust cap from the bolt hole in the top of the

chamber.

3. Insert the head of the caging bolt through the opening

and turn bolt 1/4 turn clockwise.

4. Thread the nut and washer on the bolt and turn the nut

clockwise about 18 to 21 turns. Air pressure can be

applied to the spring brake chamber through the parking

port to compress the spring while the nut is being

tightened.

5. Do not force the nut beyond its normal stop. A torque of

40.6 Nm (30 lb-ft) is the maximum that should be

required. Reverse the procedure to uncage the spring.

Removal

1. Cage the spring brake.

2. Tag, remove, and cap the air lines to the brake air

chamber.

3. Remove the pin(s) connecting the clevis to the slack

adjuster.

4. Mark the position of the clevis on push rod so that the

clevis can be reinstalled in the same position.

5. Brake is dragging. a. Low spring brake hold-off air

pressure, 70 psi (482 kPa).

a. Check for minimum spring

brake pressure, 4.82 bar (70

psi). Check for proper

functioning of air system

components.

b. Improper connection of the

service line at spring brake.

b. Check and connect line to

proper port.

c. Leaking lines or spring brake

seals.

c. Tighten connections on air

lines or replace spring brake

unit seals.

Symptom Probable Cause Solution

WARNING

Spring brake unit is powerful enough to cause parts to fly

apart with enough force to cause personal injury. The

spring brake must be caged before removing or servicing

brakes before returning the crane to service.

DANGER

Cage the spring brake before removal of air brake

chamber.

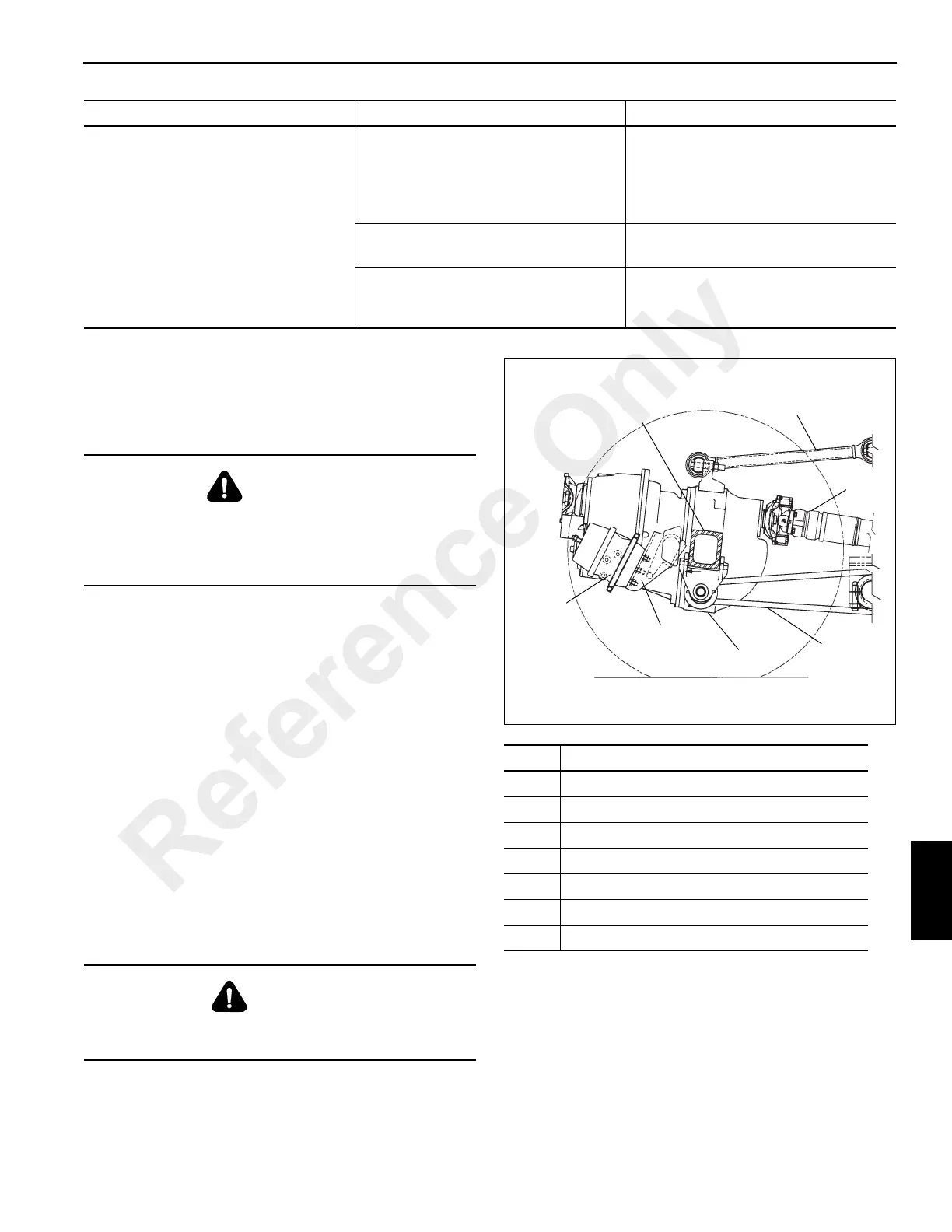

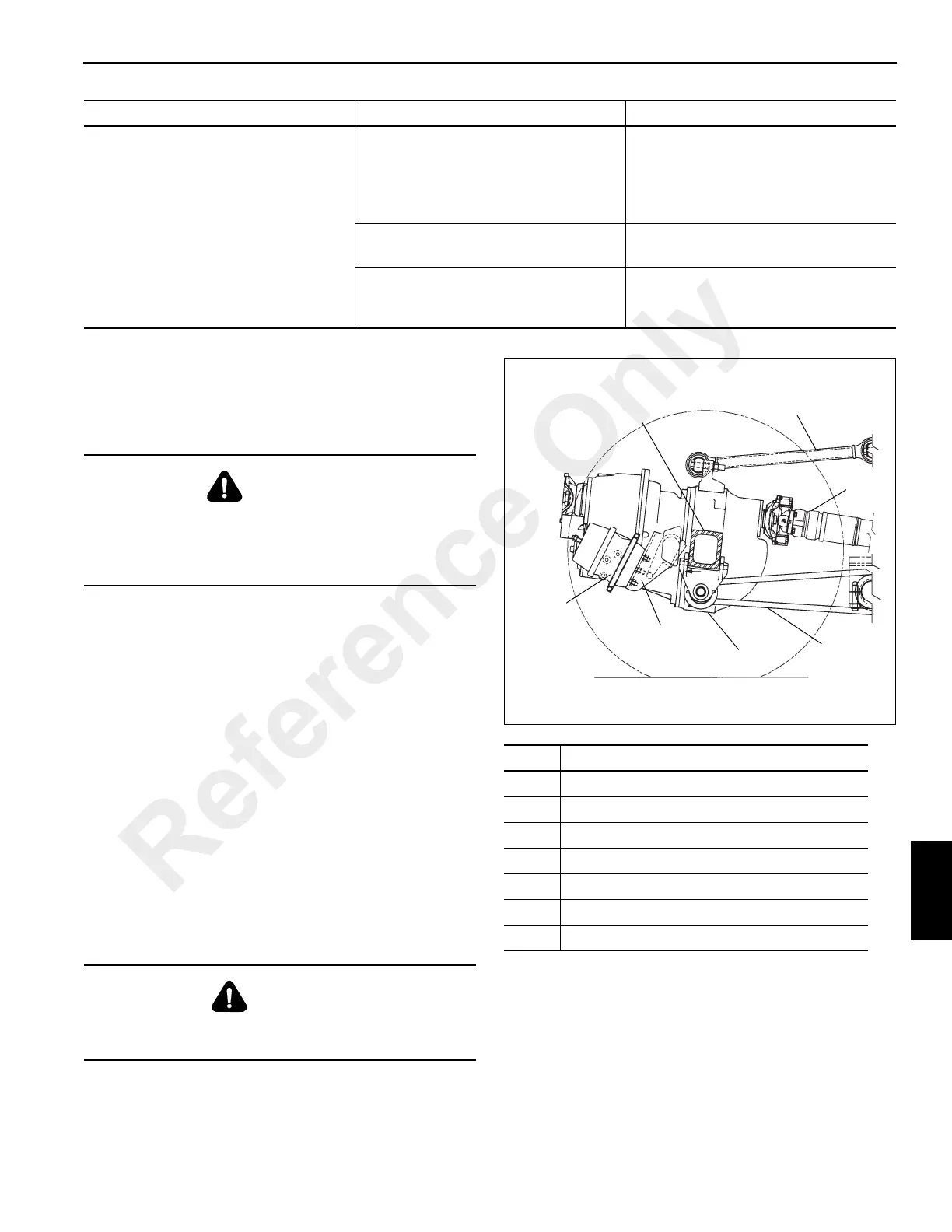

Item Description

1 Brake Air Chamber

2 Axle No. 3

3 Torque Rod

4 Drive Shaft

5 Stabilizer Beam

6 Differential

7 Mounting Bracket

Reference Only

Loading...

Loading...