Grove Published 01-29-2015, Control # 512-01 2-39

TMS700E SERVICE MANUAL HYDRAULIC SYSTEM

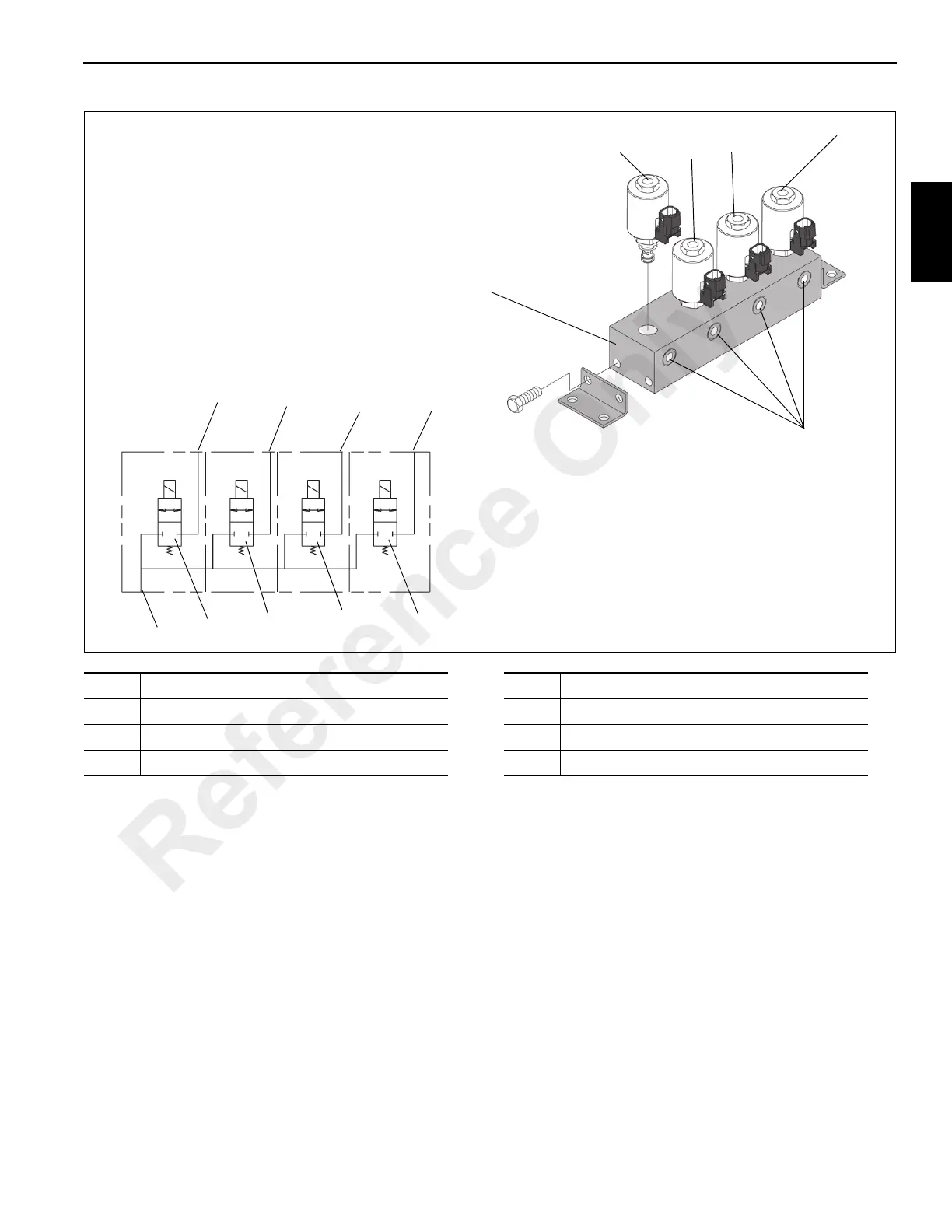

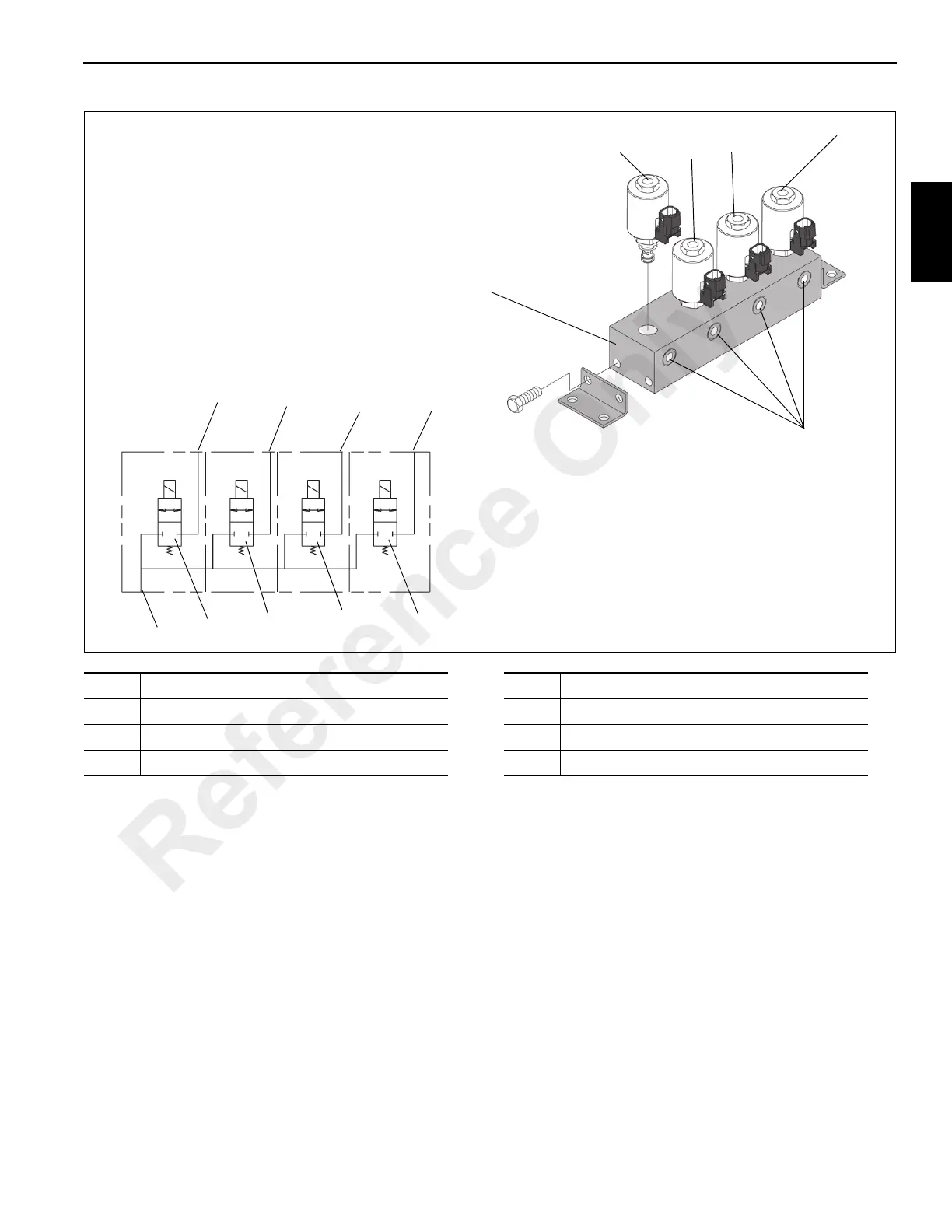

FIGURE 2-26

6137-2

6544-1

2

2

2

2

1

3

4

5

6

4

5

6

2

3

Item Description

1In Port

2Out Ports

3 Left Rear Extension Cylinder

Item Description

4 Left Rear Jack Cylinder

5 Right Rear Jack Cylinder

6 Right Rear Extension Cylinder

Reference Only

Loading...

Loading...