Manitowoc Published 05-26-17, Control # 238-02 5-1

MLC165-1 SERVICE/MAINTENANCE MANUAL HOISTS

SECTION 5

HOISTS

HOIST THEORY OF OPERATION

This section will discuss the electrical and hydraulic control

of the crane hoists. For details on individual components,

some are covered later in this section and others are

covered in Section 2 Hydraulics and Section 3 Electrical.

NOTE For a description of the overall crane hydraulic

system and additional free fall details on the

components described in this section, refer to

Section 2.

Overview of the Hoist System

Also see Figure 5-2 on page 5-2.

Each hoist system (drum 1, 2, 3, and 4) is comprised of

essentially identical control circuits and components. The

main differences between the hoists are:

• Drum 1 and 2 use identical motors. See Drum 1 and

Drum 2 Motor on page 5-5.

• Drum 3 and 4 use identical motors. See Drum 3 and

Drum 4 Motor on page 5-7.

• The control software governs the operational

characteristics differently for each hoist.

• A free fall option is available for hoists 1 and 2. See Free

Fall System (Optional) on page 5-8.

The hydraulic system for each hoist motor is comprised of a

high-volume, high-pressure circuit and a low-pressure pilot

circuit. The high-pressure, high-volume flow is supplied by

the double main pump. The pilot system is supplied by the

charge pump.

The main pump generates two flows to the control valve

manifold. The two flows can remain separate within the

manifold or they can be shared by use of the Drum Speed

switch. See Flow Sharing

on page 5-1.

For each hoist, the pilot system consists of two hydraulic

circuits which originate at the control handle in the operator

cab: an up circuit and a down circuit. Both pilot circuits

terminate at a directional control valve that is proportional

and is located on the control valve manifold.

Depending on how the directional control valve is

commanded by the control handle (by way of the pilot

system), the valve routes high pressure working flow to the A

port or the B port of the hoist motor.

Flow Sharing

NOTE The hoist motors are on an open-loop system fed

by the double main pump. This means that the

hoist motor speed can be affected by the

simultaneous operation of other crane equipment.

See Section 2 for more information on the open

loop system.

At times it may be desirable to combine the two flows from

the main pump. This can be done through the use of the

Drum Speed switch. When the switch is moved to the high

speed position, it energizes a solenoid valve located in the

control valve manifold. The solenoid valve shifts an on-off

valve which connects the load sense and working pressure

flows within the two halves of the control valve manifold.

With the Drum Speed switch in the closed position (high

speed), both of the main pump flows feed all hoist and travel

motors. In the open position (low speed), each flow

separately supplies two hoist motors and one travel motor.

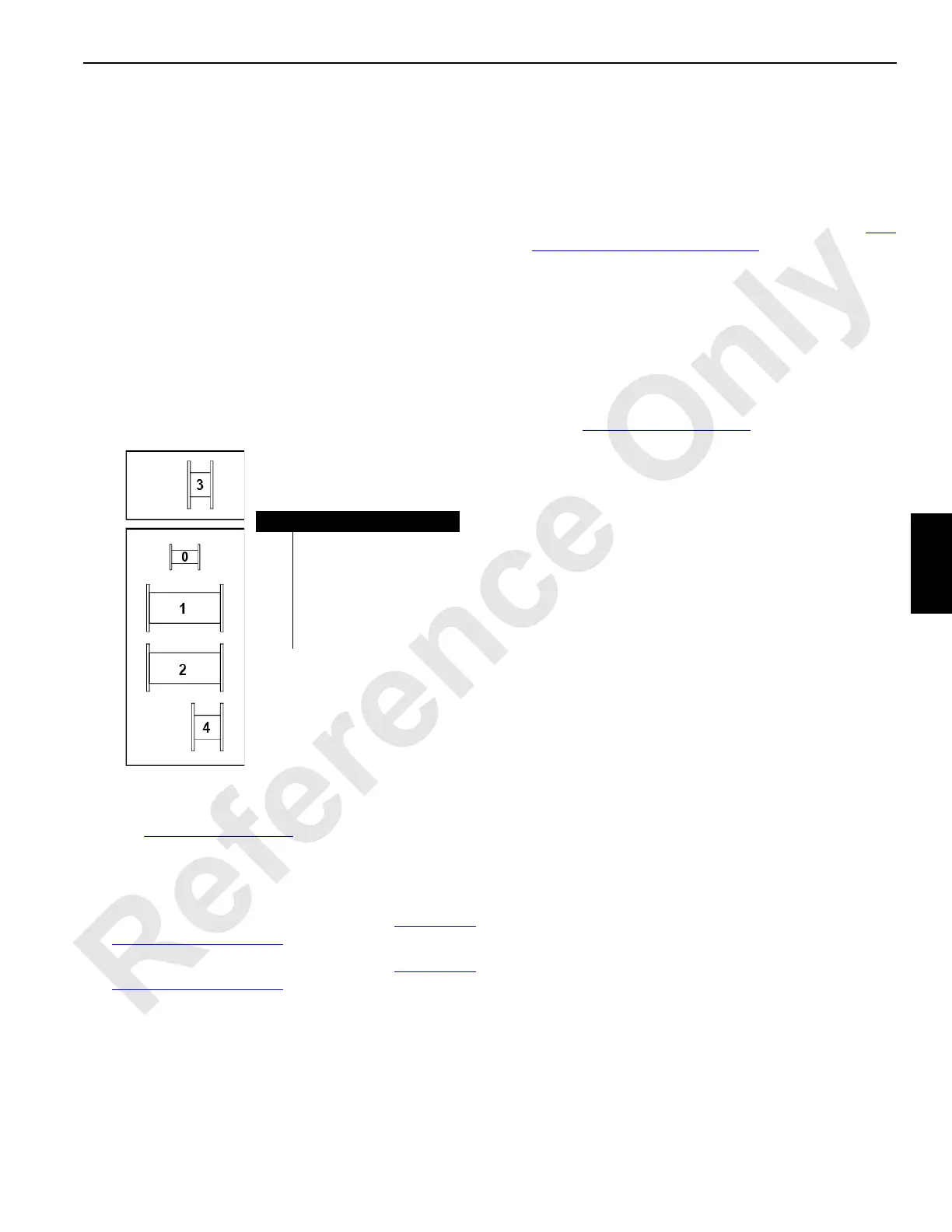

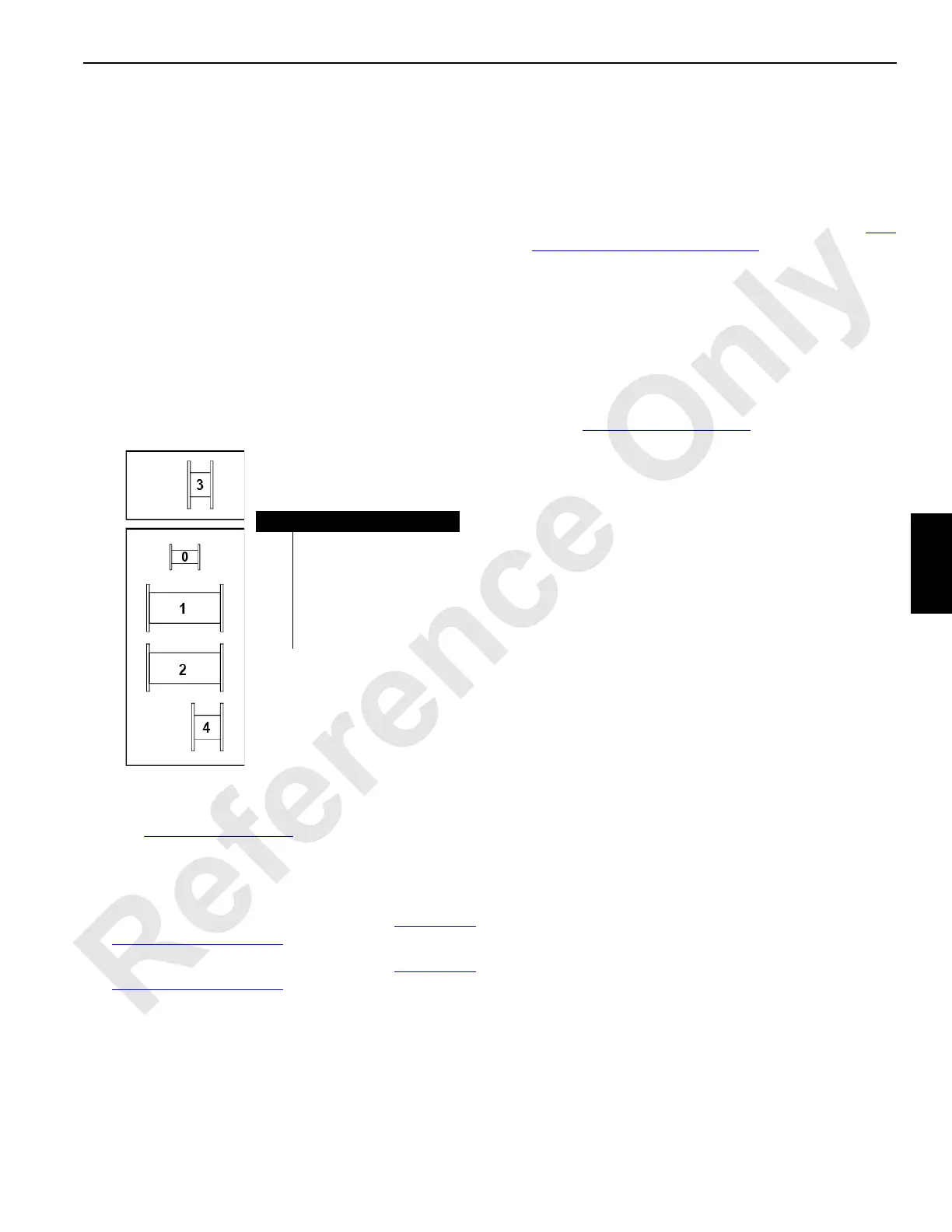

Item Description

0 Rigging Winch

1 Front Load Drum

2 Rear Load Drum

3 Auxiliary Load Drum or

Luffing Hoist (in boom butt)

4 Boom Hoist

Front of Crane

Figure 5-1. Drum Number Designations

M101099

Loading...

Loading...