Manitowoc Published 05-26-17, Control # 238-02 5-33

MLC165-1 SERVICE/MAINTENANCE MANUAL HOISTS

SPEED SENSOR—HOIST MOTORS

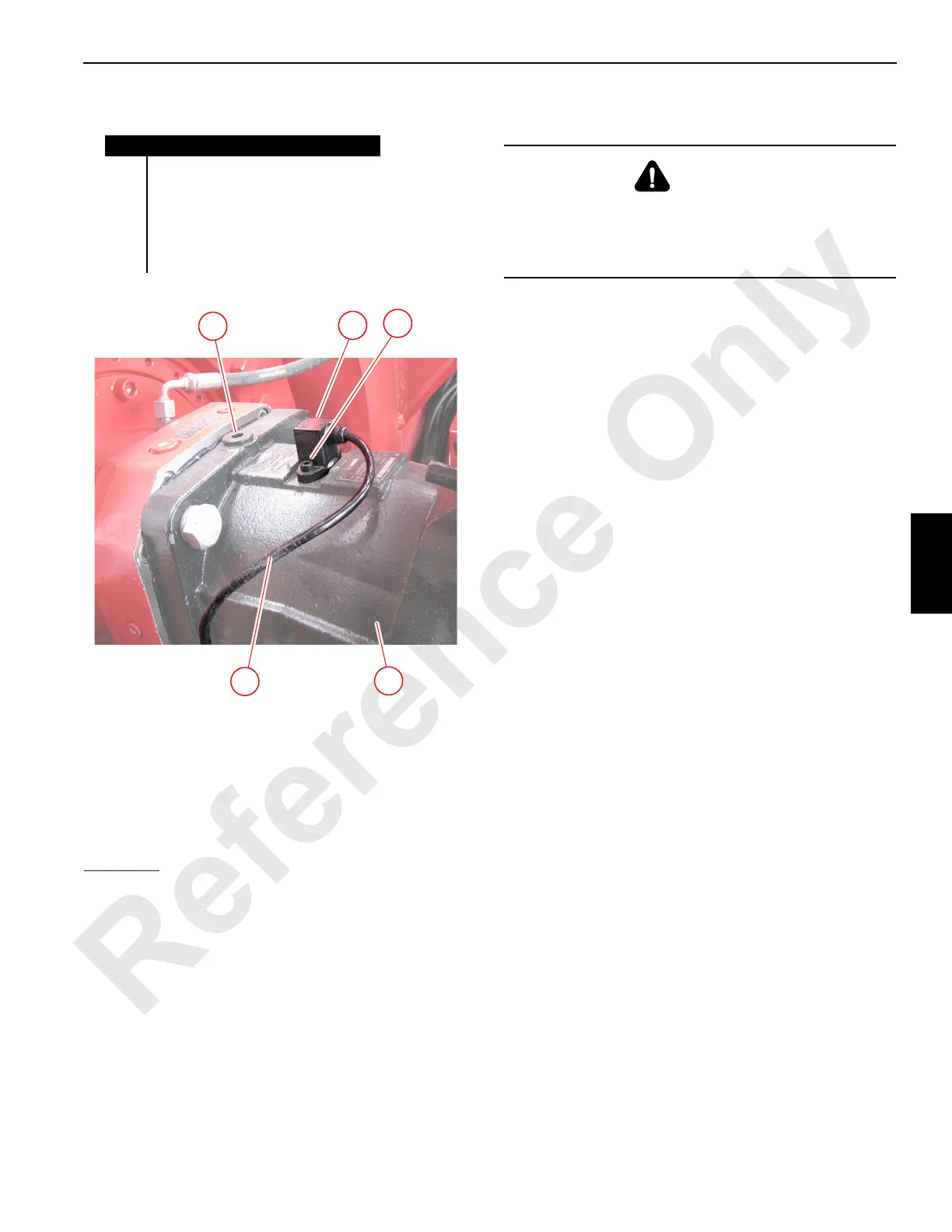

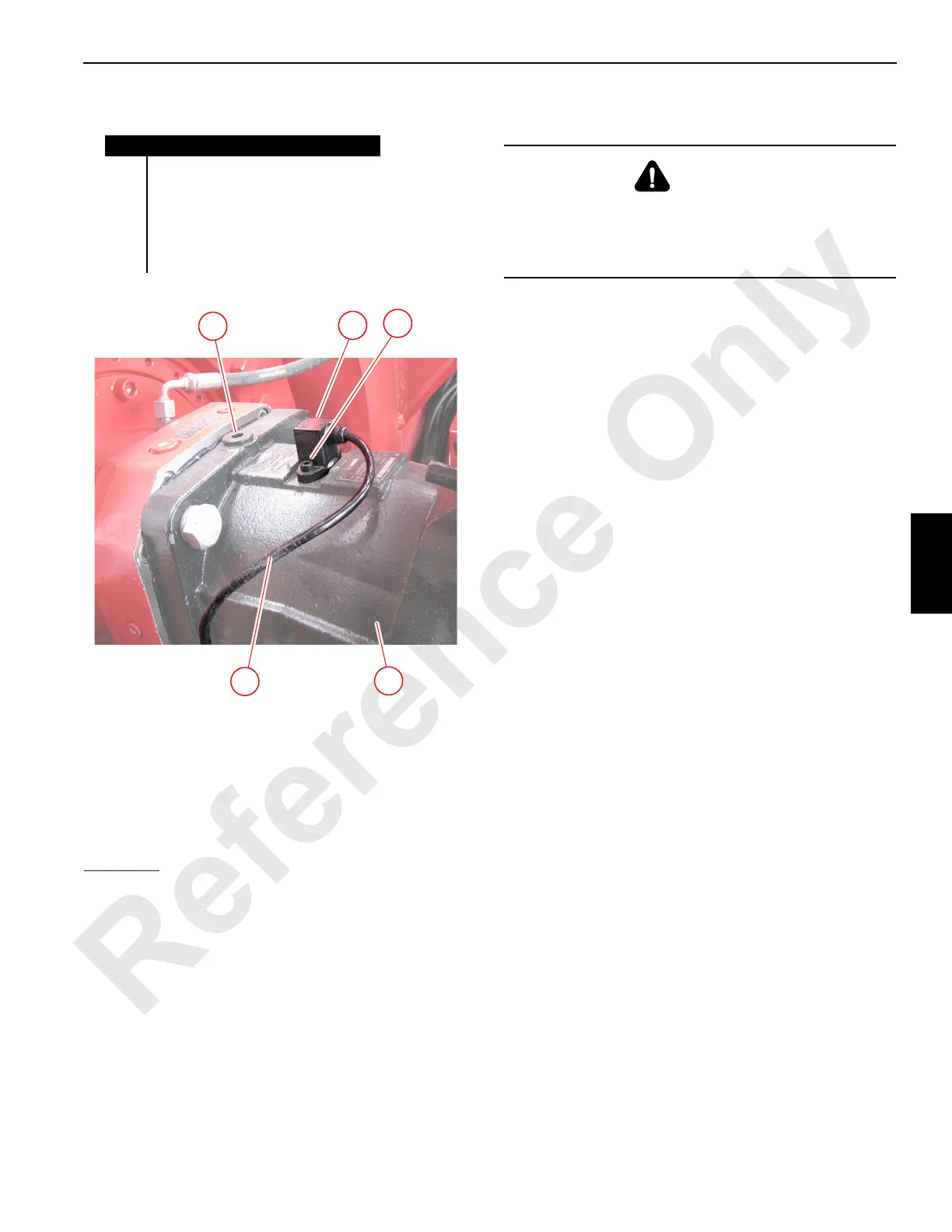

Figure 5-24

A speed sensor (1) is installed in each non-free fall hoist

motor. The sensor sends rotational speed and direction

information to the master controller to be used by the crane

control functions.

There is no adjustment for the speed sensor.

Replacement

1. Stop the engine and wait for the hydraulic oil to cool.

2. Disconnect the sensor cable (4) from the wire harness.

3. Thoroughly clean all around the sensor to prevent dirt

from entering the hydraulic system.

4. On motors positioned so that the sensor is on the

underside of the motor, place a suitable container under

the drain plug (5) and remove the drain plug.

5. Remove the two sensor mounting screws (2).

6. Remove the faulty sensor (1) with O-ring. Be careful to

contain any hydraulic fluid that might drain from the

motor.

7. Clean the mating surfaces, then install a new sensor and

O-ring.

8. Install the mounting screws to the correct torque value

for the size screw.

9. Re-connect the sensor cable to the wire harness.

10. On motors positioned so that the sensor is on the

underside of the motor:

a. Make sure that the drain plug is clean, then install

the drain plug.

b. Thoroughly clean all around the fill plug, then

remove the fill plug.

c. Fill the motor with filtered hydraulic oil of the proper

type.

d. Make sure that the fill plug is clean, then re-install

the fill plug.

11. Start the engine and operate the hoist.

12. Check for a steady drum speed (rpm) and direction

signal on the corresponding drum’s information display

in cab.

13. Make sure there is no leakage.

Figure 5-24. Motor Speed Sensor

Item Description

1 Speed Sensor (with O-ring)

2Screw (2)

3Hoist Motor

4Sensor Cable

5 Drain Plug (when motor is positioned

with sensor underneath)

1

3

2

4

M100746

5

WARNING

Burn Hazard

Oil will drain from the port when the sensor is removed.

Wait for the hydraulic oil to cool before removing the

sensor.

Loading...

Loading...