ELECTRICAL SYSTEM MLC165-1 SERVICE/MAINTENANCE MANUAL

3-4

Published 05-26-17, Control # 238-02

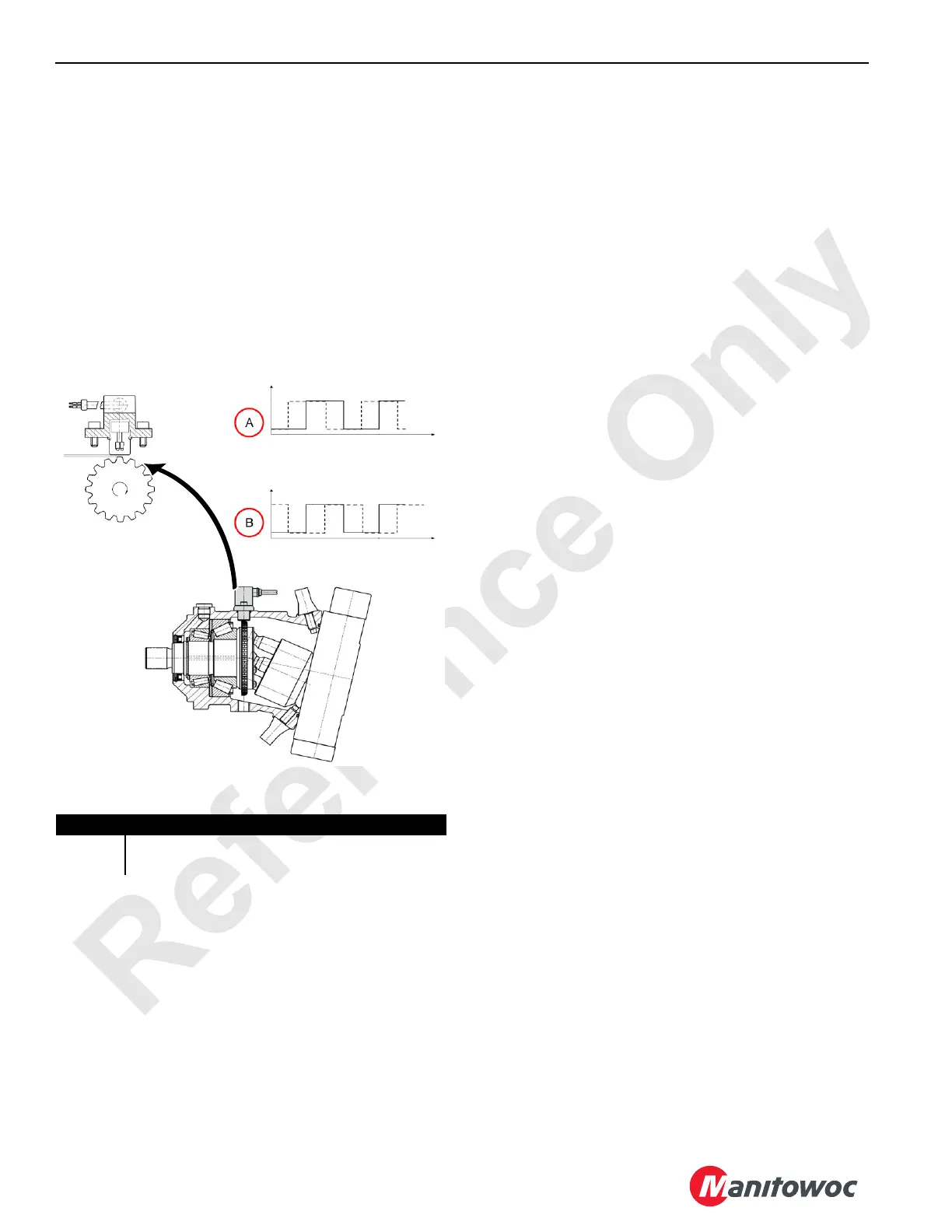

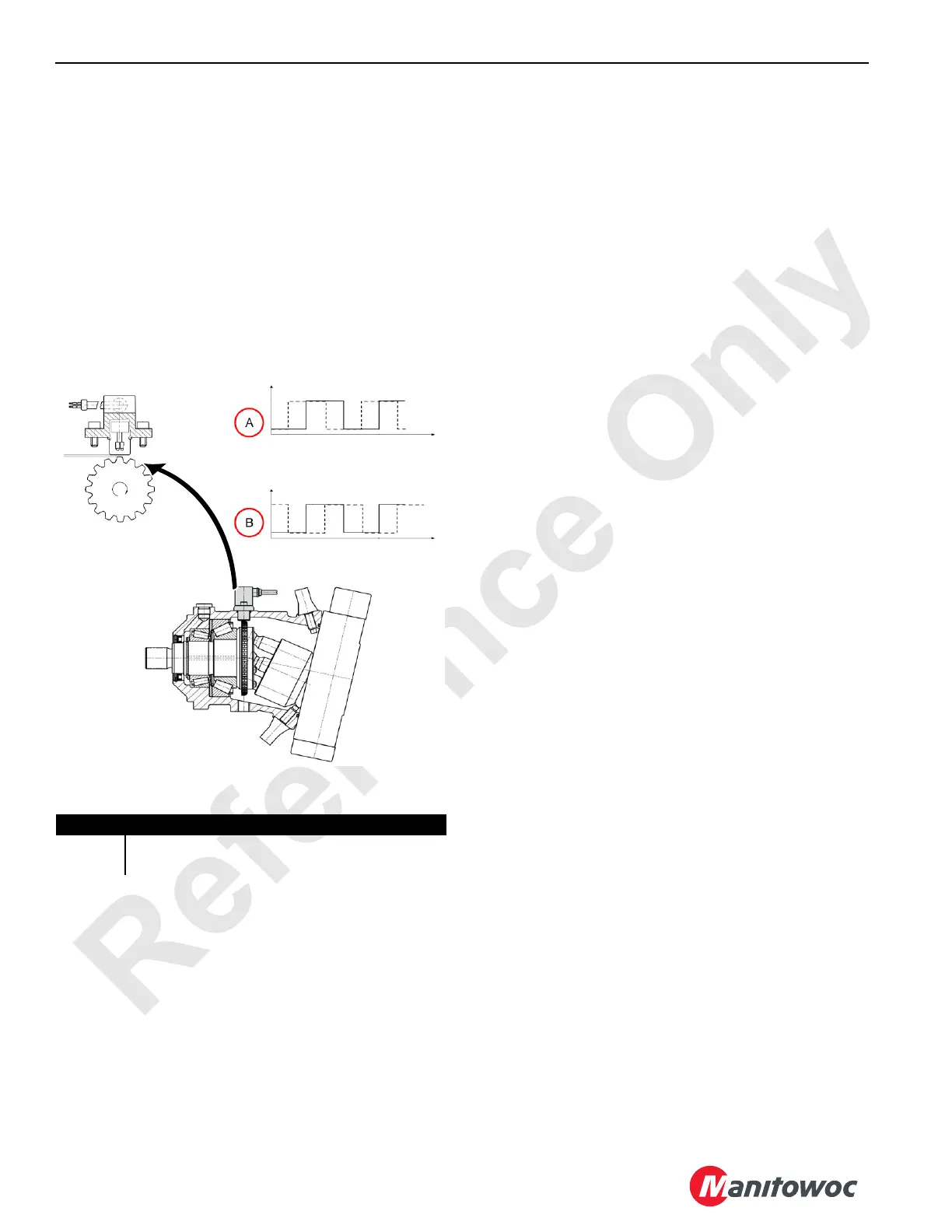

Motor Speed Sensors

A universal node provides power to Hall-effect speed

sensors within the hydraulic motors that drive the drums and

rotational bed. A gear wheel within the motor has teeth that

move past the speed sensor as a motor shaft spins, causing

the sensor to produce two square-wave signals that are

offset with a 90° phase delay.

The frequency of the square waves is determined by the

number of teeth on the circumference of the gear wheel and

shaft speed. The rotational direction is determined by which

signals phase leads the other. Software uses the square-

wave frequency and phase information to calculate the

rotational speed and direction of the motor.

Drum Free Fall Sensors

Universal node 5 provides power to an incremental encoder

within the free fall sensors of Drum 1 and 2. As drum rotation

causes the encoder shaft to rotate, the encoder produces

two square-wave signals that are offset with a 90° phase

delay.

The number of pulses produced is proportional to the

amount of shaft rotation. The rotational direction is

determined by which signals phase leads the other. Software

then uses the pulse count and phase information to calculate

drum position and rotational direction.

Limit Switches — Single Contact

In the non-tripped state, a universal node provides power to

the normally closed contact. The universal node reads the

applied power back through the normally closed contact as a

logic high. When the switch is tripped, the normally closed

contact opens, breaking the path of power through the

common terminal. The universal reads this as a logic low.

Limit Switches — Dual Contact

In the non-tripped state, a universal node provides power to

the normally closed contact and grounds the normally open

contact. The universal node reads the applied power through

the normally closed contact back through the common

center terminal as a logic high. When the switch is tripped,

the normally closed contact opens, breaking the path of

power through the common terminal. At the same time, the

normally open contact closes, grounding the common

terminal and sending the universal l node a logic low signal.

Limit switches are used to sense the travel limits of:

• Swing limit

• Drum 1 and 2 minimum bail limits

• Maximum boom angle

• Boom and luffing jib upper and lower block up limits

• Minimum and maximum luffing jib angles

Solenoids

Solenoids activate hydraulic valves and provide control of:

• Boom raise and hinge pin cylinders

• Brake cylinders

• Counterweight cylinders and pins

• Cab tilt cylinders

• Assembly cylinder

• Drum motors

• Swing motor

• Handle Selects

• Horse power over-ride

• Load sense shifting

• Travel pilot

• Pilot pressure unloading

• Cooler fan pump

• Proportional pressure control

• Free fall enables

• Auto grease control

Item Description

A Clockwise Rotation Signals

B Counter-Clockwise Rotation Signals

Figure 3-7. Motor Speed Sensor

M100821

Loading...

Loading...